Energy-saving, environment-friendly and high-efficiency battery pole piece oven

A technology for battery pole pieces, energy saving and environmental protection, applied in drying, dryers, progressive dryers, etc., can solve the problems of burnt products, less hot air circulation, and low operating efficiency, so as to increase the air flow rate, Effect of increasing drying speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

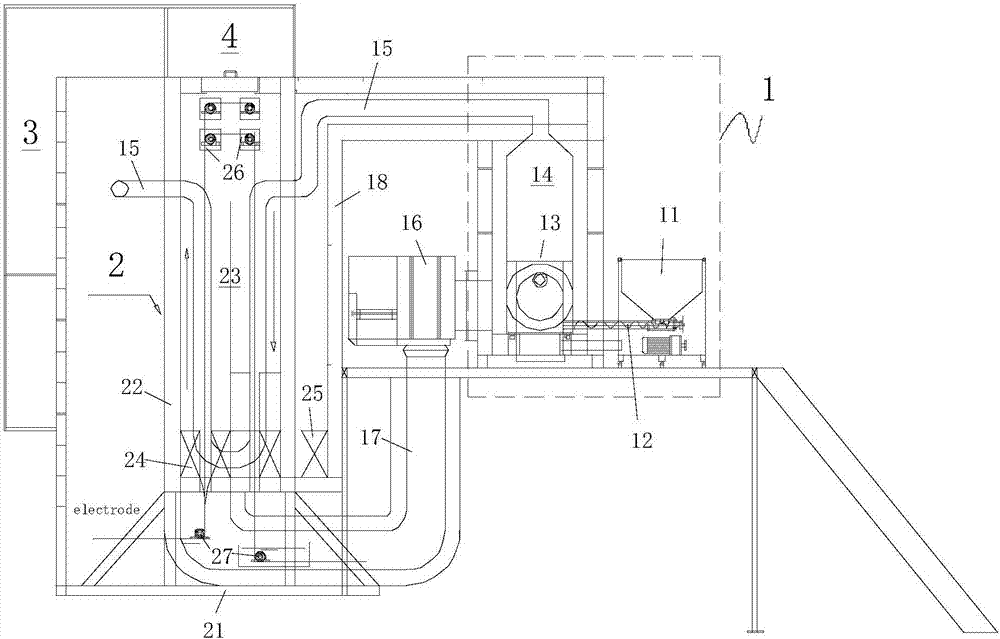

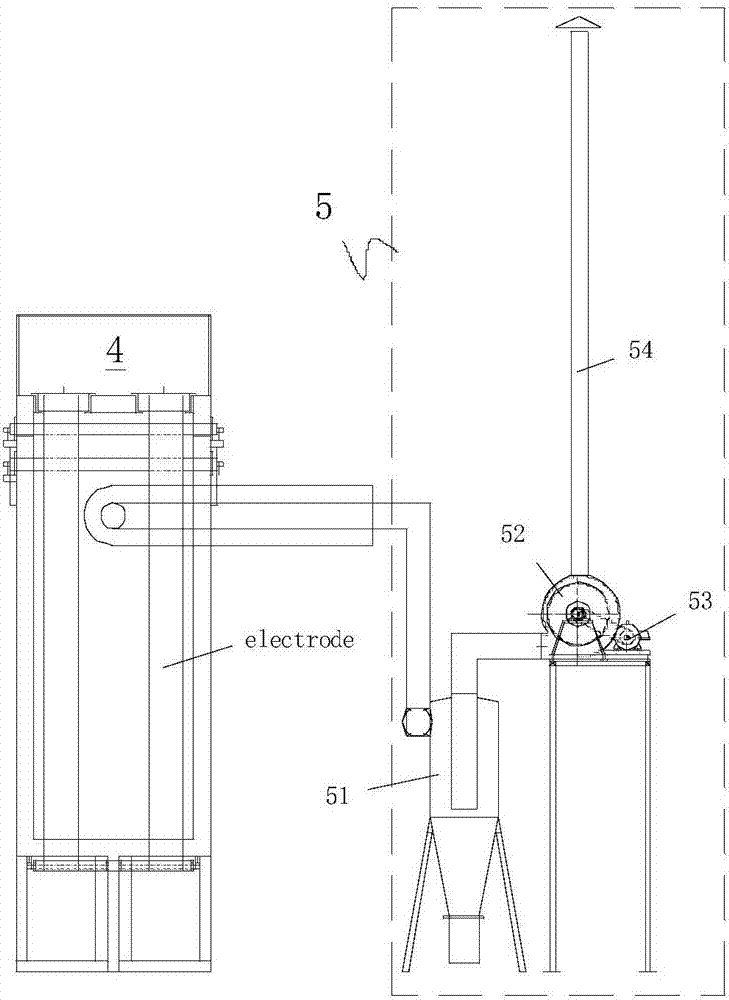

[0018] see figure 1 , figure 1 It is a structural schematic diagram of an energy-saving, environment-friendly and high-efficiency battery electrode oven in a preferred embodiment of the present invention, as figure 1 As shown, the energy-saving, environment-friendly and high-efficiency battery electrode oven provided by the present invention includes the biological particle burner 1, the oven 2, the exhaust gas treatment system 5, the steel structure 21, the biological particle burner 1, the oven 2 and the exhaust gas The processing system 5 is fixedly installed on the ground through a steel structure 21 .

[0019] The combustion material machine 1 includes a hopper 11, a screw feeder 12, a combustion chamber 13 and an inner tank 14; the feed end of the screw feeder 12 is connected to the bottom outlet of the hopper 11, and the discharge end of the screw feeder 12 is connected to the combustion chamber. The chamber 13 and the combustion chamber 13 are arranged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com