Silicon carbide semiconductor device and preparation method therefor

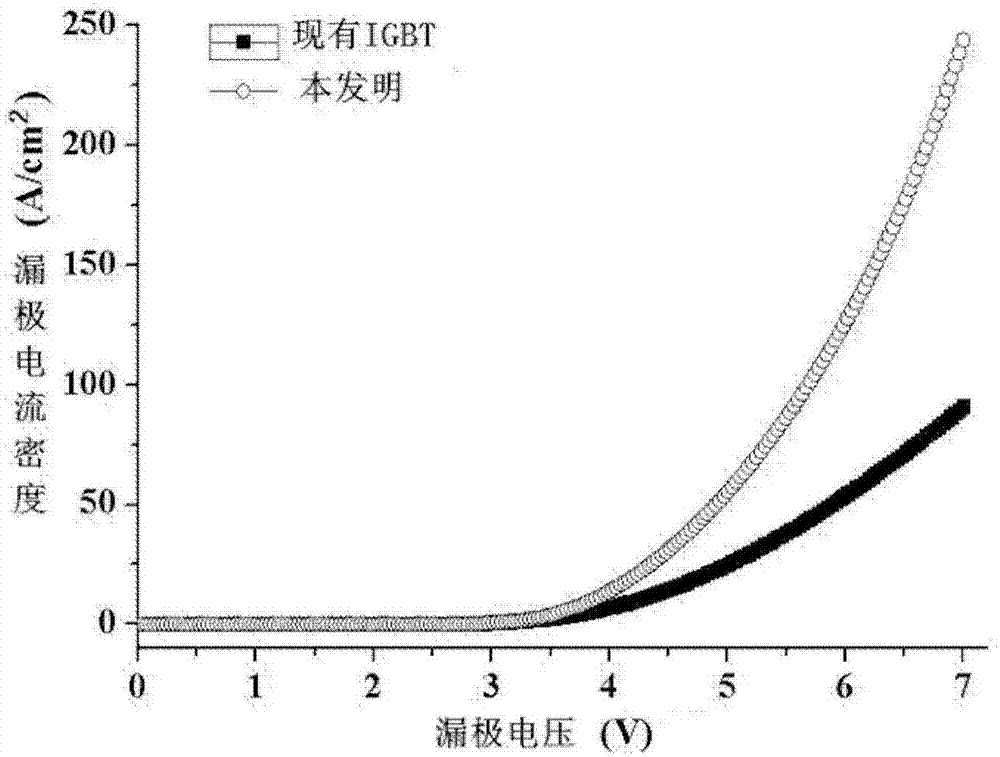

A semiconductor and silicon carbide technology, applied in the field of silicon carbide semiconductor devices, can solve the problems of limiting the application of SiCIGBT devices and high voltage drop in the drift region, achieve good conduction characteristics and switching characteristics, improve device conduction performance, and improve emitter injection than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the present invention, the directional terms such as "upper", "lower", "adjacent", "below" or "above" only refer to the directions of the attached drawings, wherein "upper", "lower", " Under" or "over" means contact or non-contact with a single or multiple elements. These directional terms are used to illustrate, not to limit the invention.

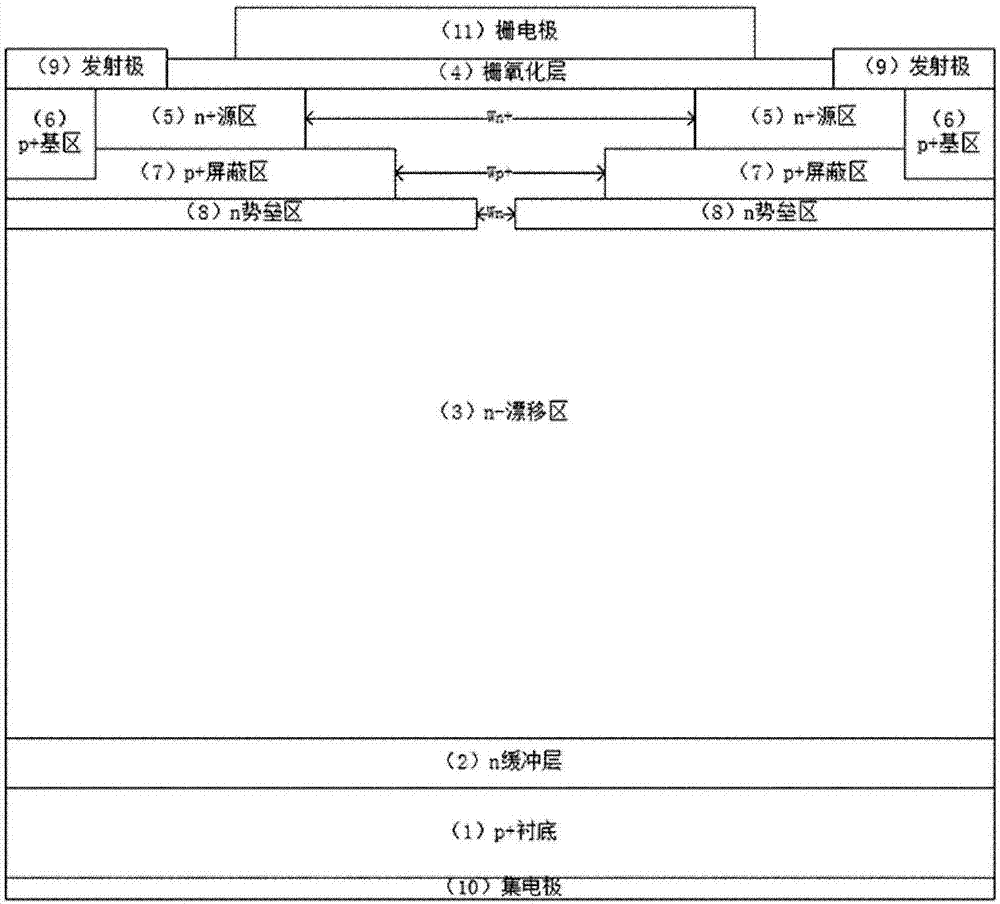

[0047] In order to reduce the high drift region resistance of the silicon carbide IGBT device, reduce the conduction voltage drop of the device, and improve the conduction capability of the silicon carbide IGBT device. The invention provides a silicon carbide device structure, which can be applied to high-voltage conditions such as traction transmission and smart grids. In addition, the device can also greatly increase the carrier concentration in the drift region during the conduction process of the device, so that the conduction of the device It has an extremely low drift region on-resistance when on.

[0048] In order to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com