Planar junction perovskite solar cell and fabrication method thereof

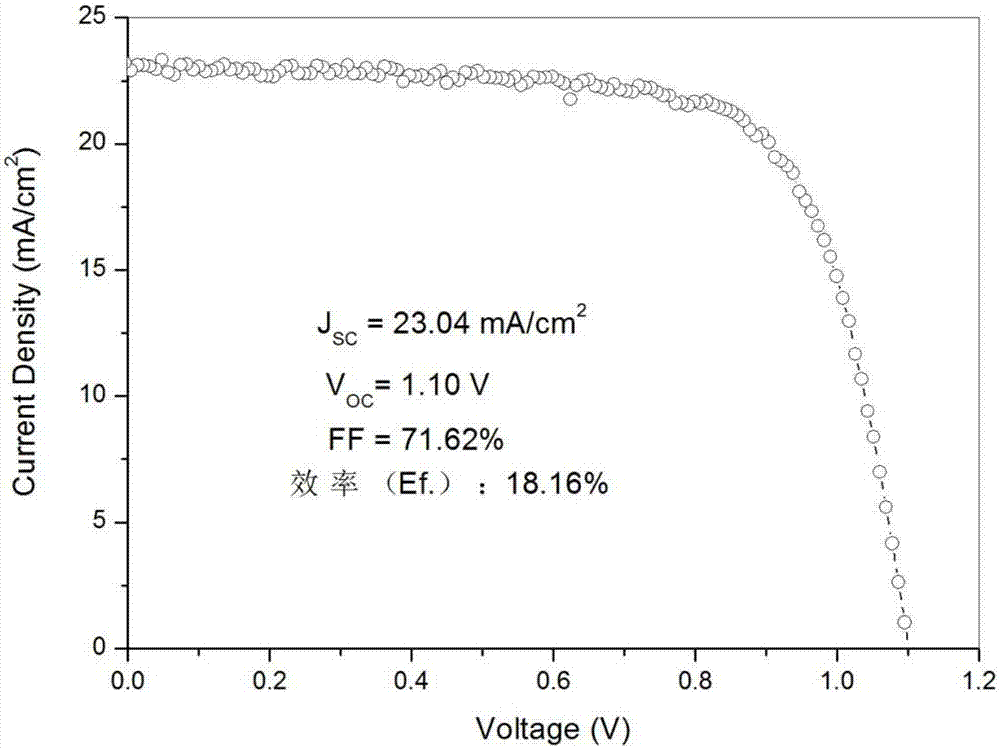

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as high energy consumption and complex process, and achieve the effects of simple cost, optimized device structure, and efficient absorption and conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Clean the substrate

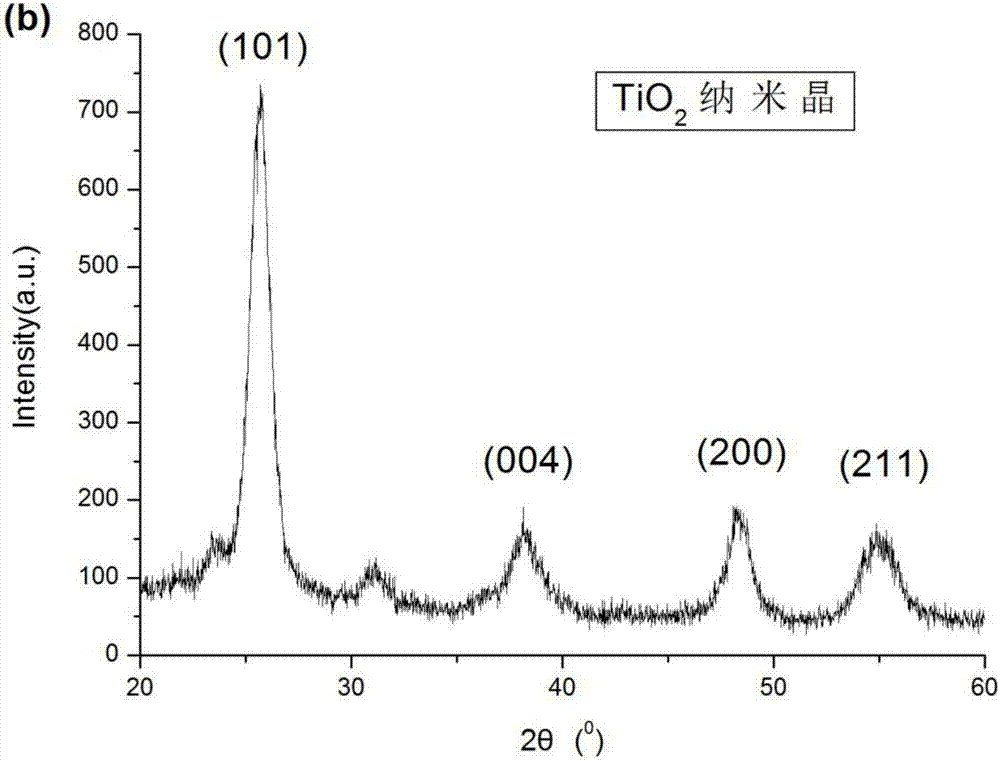

[0040] (2) Prepare the solution: Mix 50ml of titanium isopropoxide and 30ml of isopropanol to form a precursor solution for later use, then take 100ml of distilled water and place it in a round-bottomed flask and add 1ml of hydrochloric acid, and keep stirring at 600r.p.m. / min Stir, slowly add the titanium isopropoxide precursor solution drop by drop to the continuously stirring distilled water, heat at 60°C for 4 hours and hydrolyze to obtain a titanium dioxide glue;

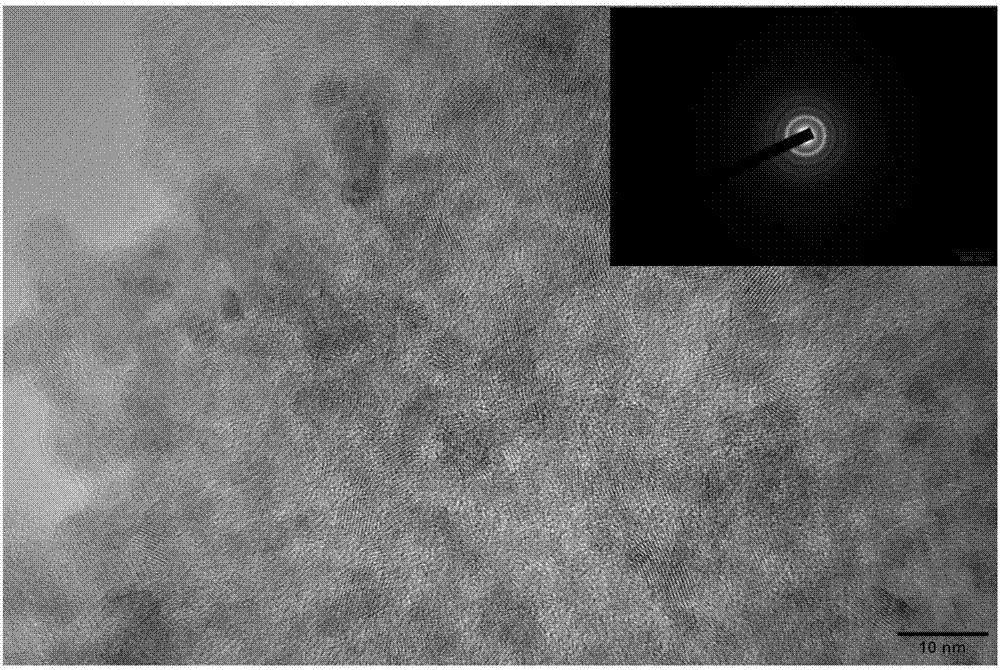

[0041] (3) Spin-coat anatase-type titanium dioxide nanocrystals: use a spin coater to spin-coat 1 to 5 layers of dense titanium dioxide layered structures on the above substrate. 4000r.p.m. / min, spin coating time is 50s;

[0042] (4) spin coating perovskite absorbing layer: utilize two-step method to prepare perovskite absorbing layer, first spin-coat one deck PbI on the dense titanium dioxide layered structure described in step (3) 2 thin film, and then spin-coat formamidine ...

Embodiment 2

[0048] (1) Clean the substrate

[0049](2) Preparation of solution: Mix 20-80ml of titanium tert-butoxide and 10-60ml of isopropanol to form a precursor solution for later use, then take 50-150ml of distilled water and place it in a round-bottomed flask and add 0.5-3ml of hydrochloric acid. Stir continuously at 200-600r.p.m. / min, slowly add titanium isopropoxide precursor solution drop by drop to the continuously stirred distilled water, heat at 50-95°C for 1h-6h to obtain titanium dioxide glue;

[0050] (3) Spin-coat anatase titanium dioxide nanocrystals: use a spin coater to spin-coat 1 to 5 layers of dense titanium dioxide layered structures on the above substrate, the specific parameters are: each layer uses 30μL-60μL titanium dioxide glue, The coating speed is 3000~4000r.p.m. / min, and the spin coating time is 50s~60s;

[0051] (4) spin coating perovskite absorbing layer: utilize two-step method to prepare perovskite absorbing layer, first spin-coat one deck PbI on the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com