Lithium ion battery piezoelectric positive electrode composite pole piece and lithium ion battery application thereof

A technology of lithium ion battery and positive electrode plate, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as poor safety performance, achieve low expansion rate, strong adhesion, and improve conduction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

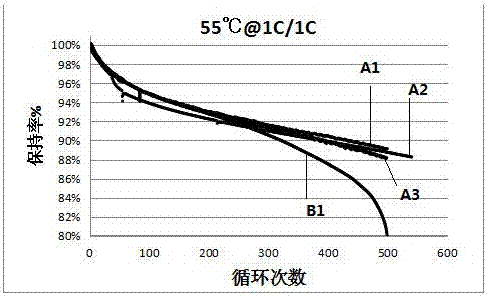

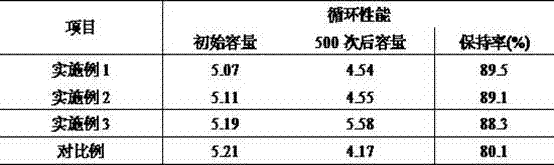

Examples

Embodiment 1

[0020] Preparation of lithium-ion battery piezoelectric cathode composite pole piece:

[0021] Weigh 8.5g of polyvinylidene fluoride and 1.5g of polystyrene carbonate and add them to 500g of N-methylpyrrolidine, and disperse evenly to obtain a binder solution; then weigh 1.5 times the binder solution, and add 5g of oxidation Graphene and 5g of alkyl glucoside thereof, and uniformly dispersed, then added 70g of barium titanate ceramic material, and uniformly dispersed by a ball mill to obtain piezoelectric ceramic composite slurry;

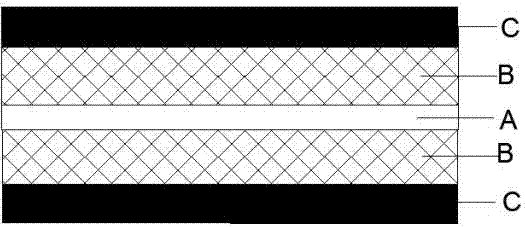

[0022] At the same time, weigh 5g of polyvinylidene fluoride, dissolve it in 200g of N-methylpyrrolidone and disperse evenly, then add 5g of SP conductive agent and its 90g of LiNi 1 / 3 co 1 / 3 mn 1 / 3 O2 The ternary material prepares the slurry, and then coats the slurry on the upper surface of the positive electrode aluminum foil current collector A by a coating machine, and obtains the positive electrode sheet containing the active material layer...

Embodiment 2

[0025] Weigh 8.0g of polyvinylidene fluoride and 2.0g of polystyrene carbonate and add them to 500g of N-methylpyrrolidine, disperse evenly to obtain a binder solution; then weigh the above binder solution, and add 1g of vapor phase growth Carbon fiber and 1g of ammonium oxide are uniformly dispersed, then 80g of lead titanate ceramic material is added, and uniformly dispersed by a ball mill to obtain piezoelectric ceramic composite slurry;

[0026] At the same time, weigh 5g of polyvinylidene fluoride, dissolve it in 200g of N-methylpyrrolidone and disperse evenly, then add 5g of SP conductive agent and its 90g of LiNi 1 / 3 co 1 / 3 mn 1 / 3 O2 The ternary material prepares a slurry, and then coats the slurry on the upper surface of the positive electrode aluminum foil current collector A by a coating machine, and obtains a positive electrode sheet containing an active material layer B on the surface of the current collector after drying;

[0027] Afterwards, the piezoelectric c...

Embodiment 3

[0029] Weigh 9.0g of polyvinylidene fluoride and 1.0g of polystyrene carbonate and add it to 500g of N-methylpyrrolidine, and disperse evenly to obtain a binder solution; then weigh 2 times the binder solution and add 10g of carbon Nanotubes and 10g of glyceride thereof, and uniformly dispersed, then added 60g of lead magnesium niobate ceramic material, and uniformly dispersed by a ball mill to obtain piezoelectric ceramic composite slurry;

[0030] At the same time, weigh 5g of polyvinylidene fluoride, dissolve it in 200g of N-methylpyrrolidone and disperse evenly, then add 5g of SP conductive agent and its 90g of LiNi 1 / 3 co 1 / 3 mn 1 / 3 O2 The ternary material prepares a slurry, and then coats the slurry on the upper surface of the positive electrode aluminum foil current collector A by a coating machine, and obtains a positive electrode sheet containing an active material layer B on the surface of the current collector after drying;

[0031] Afterwards, the piezoelectric c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com