An improved stripline high-power microwave switch and its manufacturing method

A technology for microwave switches and manufacturing methods, which is applied in the direction of waveguide devices, circuits, electrical components, etc., can solve the problems of harsh assembly process requirements, high welding process requirements, and difficult reliability guarantees, and achieve low-loss microwave signal transmission and improve The effect of carrying high power and short switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

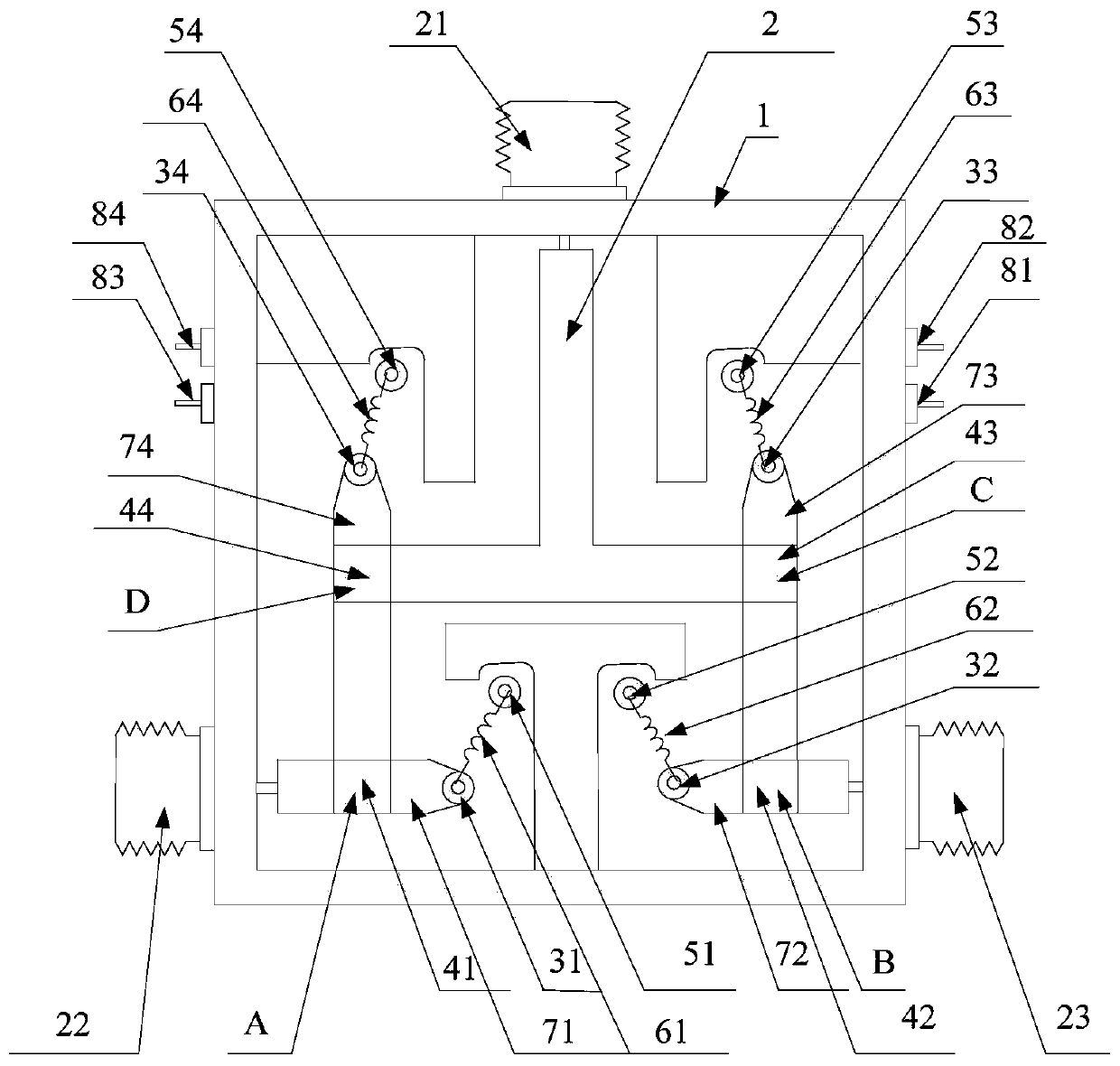

[0037] Below in conjunction with accompanying drawing, the present invention is described in further detail:

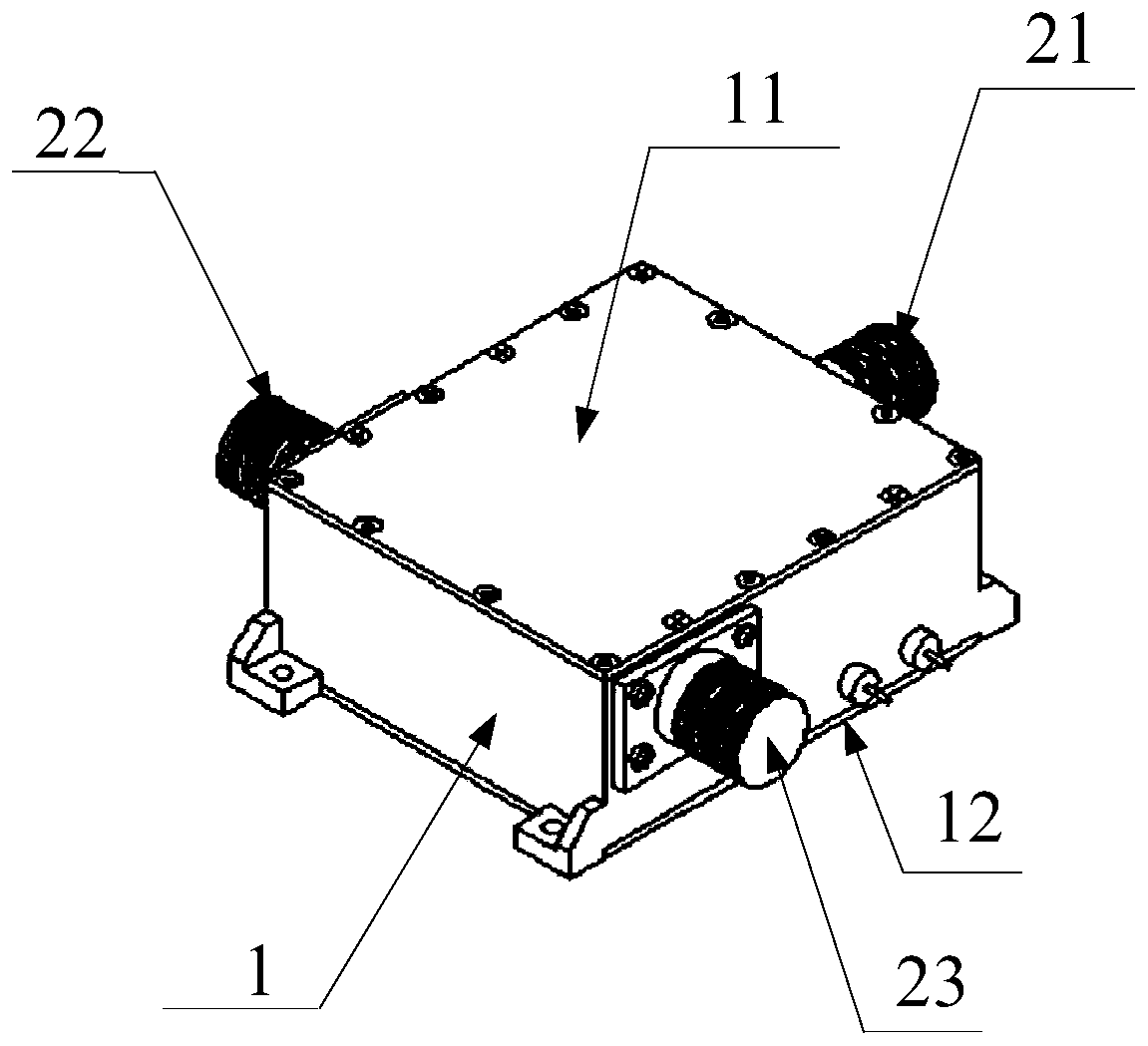

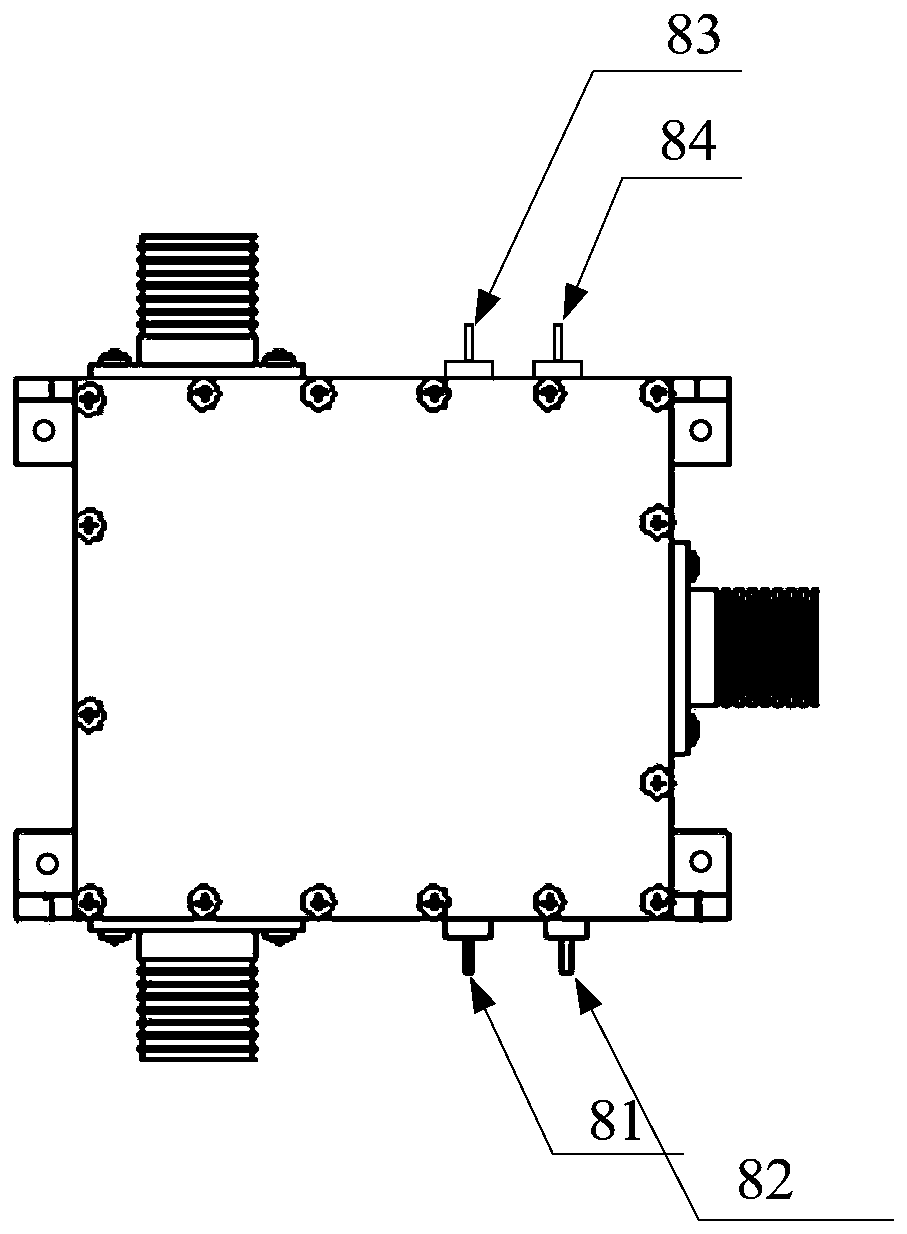

[0038] figure 1 It is a structural schematic diagram of the improved stripline high-power microwave switch of the present invention; Picture 1-1 It is another structural schematic diagram of the improved stripline high-power microwave switch of the present invention; figure 2 It is a partial schematic diagram of the internal structure of the improved stripline high-power microwave switch of the present invention. combine figure 1 , Picture 1-1 and figure 2 , the manufacturing method of the improved stripline high-power microwave switch comprises the following steps:

[0039] Step 1: Connect the first high-frequency socket 21, the second high-frequency socket 22, and the third high-frequency socket 23 with the microwave switch box body 1;

[0040] Step 2: Weld the center conductor core wire 2 with the core wire of the first high-frequency socket 21 installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com