A synthetic method of gold nanoparticle catalysts having a controllable dimension, gold catalysts and applications of the catalysts

A technology of gold nanoparticle and synthesis method, applied in the field of gold nanoparticle catalyst synthesis, can solve the problems of easy aggregation, poor stability, difficulty in large-scale production, poor monodispersity, etc., and achieves good high temperature stability, easy control, and avoidance of loss. and the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

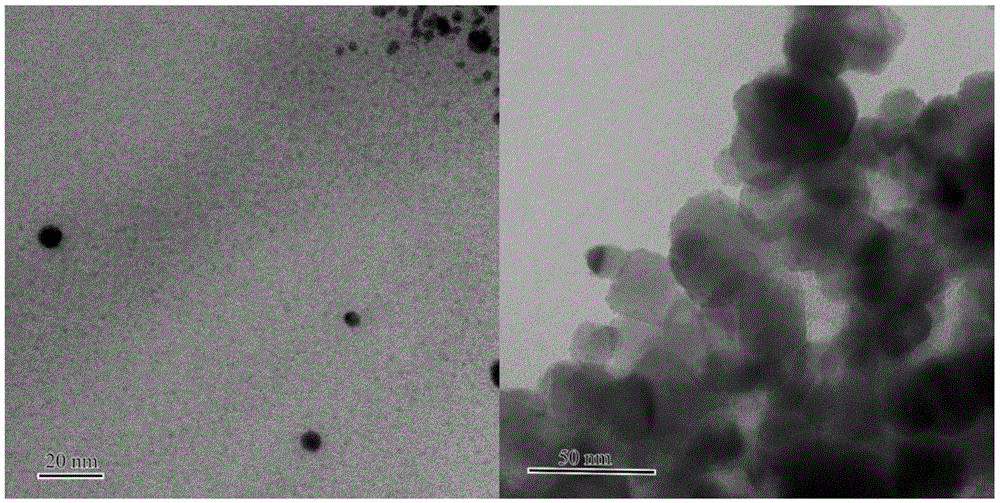

[0033] Embodiment 1: 1wt% Au / TiO with a diameter of about 1 nanometer of Au nanoparticles 2 Synthesis.

[0034] The mass concentration is 0.084mg.ml -1 The polyvinyl alcohol was added to a concentration of 1.6 mM HAuCl 4 solution, stirred for 30min to mix well. Weigh 10.7-11.0 mg of .075 times the molar equivalent of NaBH 4 Dissolve in 40mL of deionized water, take half of it and pour it into the above-mentioned protected chloroauric acid mixed solution for direct reduction to obtain a purple-brown colloidal solution. Add carrier TiO directly after reducing 3-5mim 2 , the measured pH value of the colloid is about 3, and the change is not significant after adding the carrier. Stirring and loading for 60 minutes, a blue-purple slurry was obtained, and after suction filtration, washing and drying in a vacuum oven, a blue-purple powder sample was obtained. Place the solid sample in a quartz tube at 3%% O 2 Oxidation treatment was carried out at 250°C for 4 hours at 250°C (a...

Embodiment 2

[0037] Embodiment 2: The proportion of reducing agent is different: 1wt% Au / TiO with a diameter of about 1.5 nanometers of Au nanoparticles 2 Synthesis.

[0038] The mass concentration is 0.084mg.ml -1 The polyvinyl alcohol was added to a concentration of 1.6 mM HAuCl 4 solution, stirred for 30min to mix well. Weigh 18.0-18.2 mg of 1.25 times the molar equivalent of NaBH 4 Dissolve in 40mL of deionized water, take half of it and pour it into the above-mentioned protected chloroauric acid mixed solution for direct reduction to obtain a purple-brown colloidal solution. Add carrier TiO directly after reducing 3-5mim 2 , the pH value of the colloid was measured to be around 3.2, and there was little change after adding the carrier. Stirring and loading for 60 minutes, a blue-purple slurry was obtained, and after suction filtration, washing and drying in a vacuum oven, a blue-purple powder sample was obtained. Place the solid sample in a quartz tube at 20% O 2 Oxidation trea...

Embodiment 3

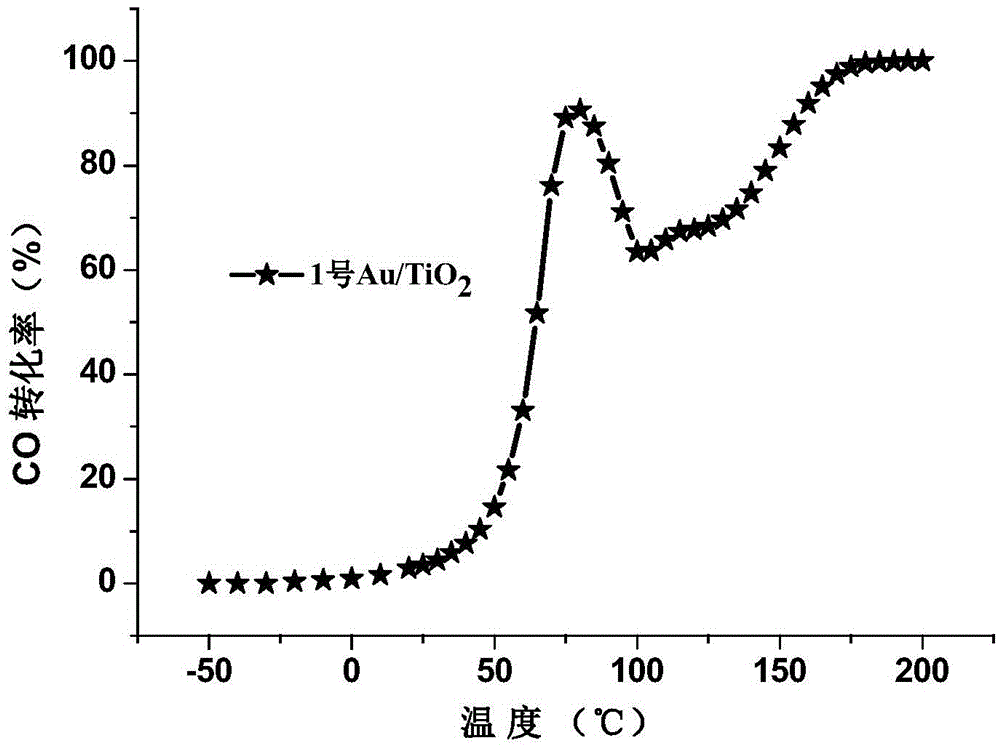

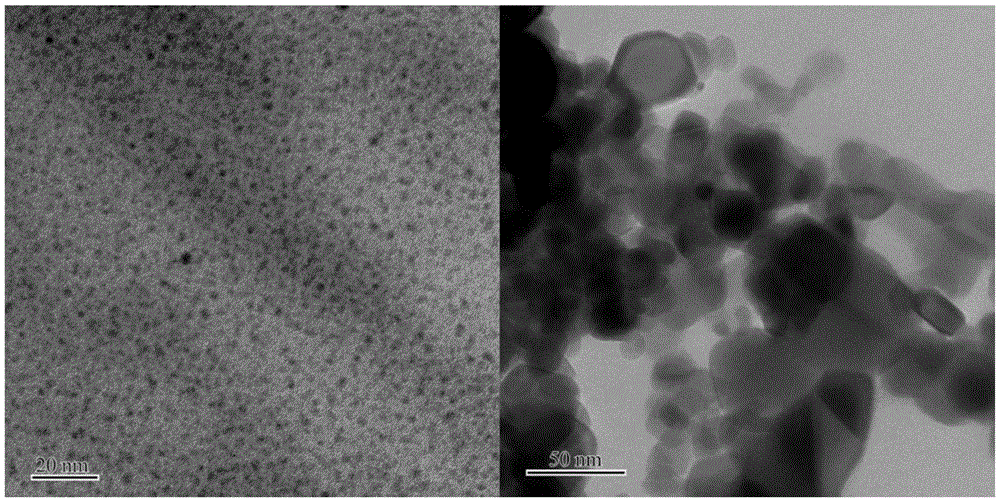

[0041] Embodiment 3: The proportion of reducing agent is different: 1wt% Au / TiO with Au nanometer particle diameter of about 3 nanometers 2 Synthesis.

[0042] The mass concentration is 0.084mg.ml -1 The polyvinyl alcohol was added to a concentration of 1.6 mM HAuCl 4solution, stirred for 30min to mix well. Weigh 36.2-36.4 mg of 5 times the molar equivalent of NaBH 4 Dissolve it in 20mL of deionized water, and pour it all at once into the above-mentioned protected chloroauric acid mixed solution for direct reduction to obtain a brown-red colloidal solution. Add carrier TiO directly after reducing 3-5mim 2 , the pH value of the colloid is measured at 5-6, and the change is not significant after adding the carrier. Stirring and loading for 60 minutes, a brown-red slurry was obtained, and after suction filtration, washing and drying in a vacuum oven, a brown-red powder sample was obtained. Place the solid sample in a quartz tube in 10% O 2 Oxidation treatment was carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com