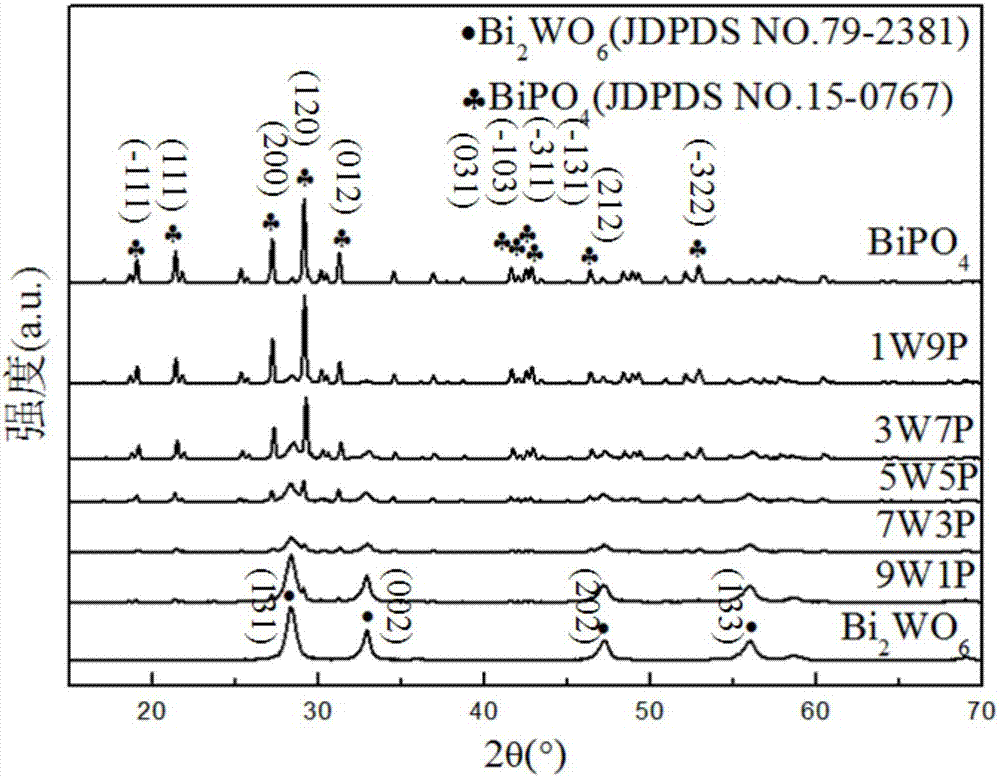

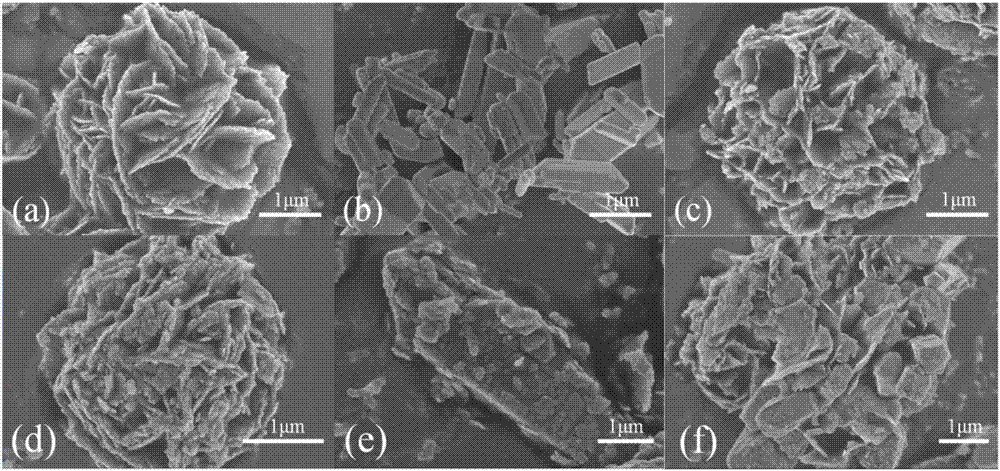

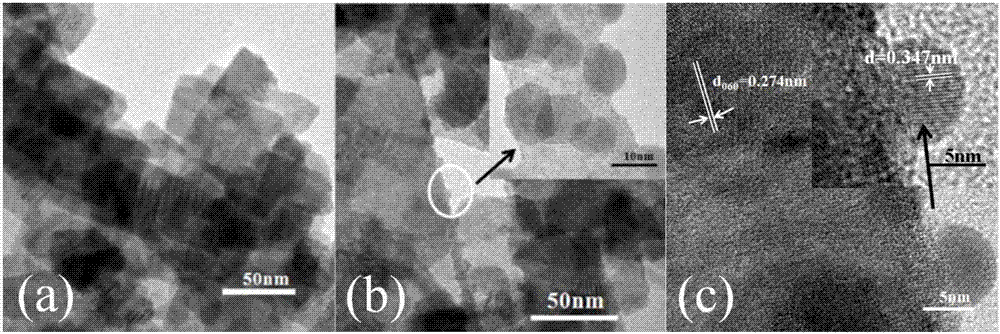

Bismuth tungstate/bismuth phosphate heterojunction photocatalyst and preparation method and application thereof

A photocatalyst, bismuth phosphate technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sewage treatment, etc., to achieve high crystallinity, improved photocatalytic performance, and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water, stir vigorously for 20min to obtain a white mixed solution, the concentration of Bi element in the mixed solution is 0.133mol / L, ultrasonically disperse the mixed solution in an ultrasonic instrument with a power of 400W for 30min, and then at room temperature with 300rad / L Min speed magnetic stirring for 2 hours, and finally transferred to a hydrothermal reaction kettle with a microwave power of 300W, microwave hydrothermal reaction at 180°C for 1 hour, and a white mixed solution was obtained. The precipitate was washed three times with absolute ethanol and deionized water, and dried at 80 °C for 15 h to obtain white Bi 2 WO 6 Powder;

[0034] Step 2: Add 3mmol Na 3 PO 4 , 3mmol Bi(NO 3 ) 3 and 5mL of 1mol / L nitric acid solution were dissolved in deionized water, and after stirring, a white mixed solution was obtained. The concentration of Bi element in the mixed soluti...

Embodiment 2

[0037] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water, stir vigorously for 20min to obtain a white mixed solution, the concentration of Bi element in the mixed solution is 0.14mol / L, ultrasonically disperse the mixed solution in an ultrasonic instrument with a power of 500W for 20min, and then at room temperature at 350rad / L Magnetically stirred for 1.5 hours at a speed of min, and finally transferred to a hydrothermal reaction kettle with a microwave power of 300W. Microwave hydrothermal reaction was carried out at 190°C for 0.8 hours to obtain a white mixed solution. The mixed solution was left to stand for stratification, and the supernatant was removed. , the precipitate was washed three times with absolute ethanol and deionized water, and dried at 75 °C for 18 h to obtain white Bi 2 WO 6 Powder;

[0038] Step 2: Add 3mmol Na 3 PO 4 , 3mmol Bi(NO 3 ) 3 and 4mL 1mol / L nitric acid solution were dissolved in deionized water...

Embodiment 3

[0041] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water, stir vigorously for 20min to obtain a white mixed solution, the concentration of Bi element in the mixed solution is 0.145mol / L, ultrasonically disperse the mixed solution in an ultrasonic instrument with a power of 450W for 25min, and then at room temperature with 400rad / L Magnetically stirred at a speed of min for 1 hour, and finally transferred to a hydrothermal reaction kettle with a microwave power of 300W, microwave hydrothermal reaction at 200°C for 0.5 hours, and a white mixed solution was obtained. The precipitate was washed three times with absolute ethanol and deionized water, and dried at 70 °C for 20 h to obtain white Bi 2 WO 6 Powder;

[0042] Step 2: Add 3mmol Na 3 PO 4 , 3mmol Bi(NO 3 ) 3 and 4.5mL 1mol / L nitric acid solution were dissolved in deionized water, and a white mixed solution was obtained after stirring. The concentration of Bi element in the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com