A kind of preparation method of nano-micron multi-level structure composite glass fiber

A glass fiber and nanotechnology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of high hardness, smooth surface and weak bonding force with the substrate, easy wear of materials, etc. firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

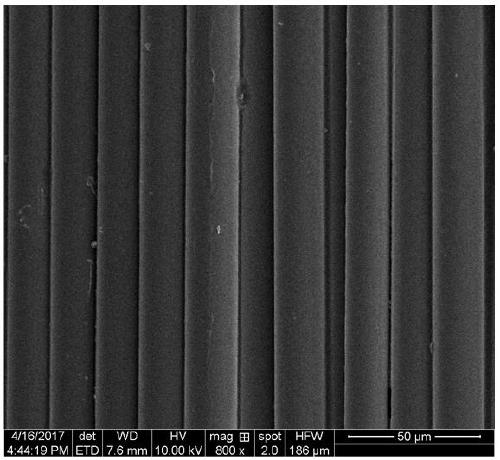

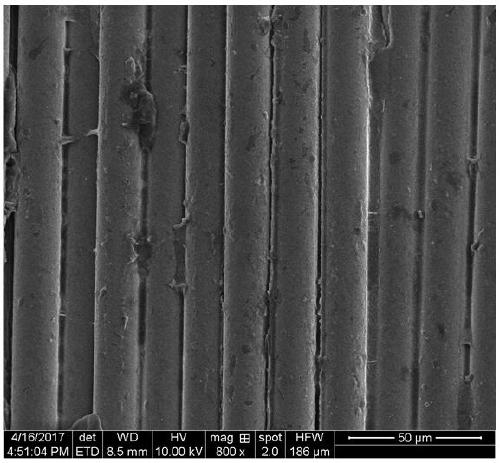

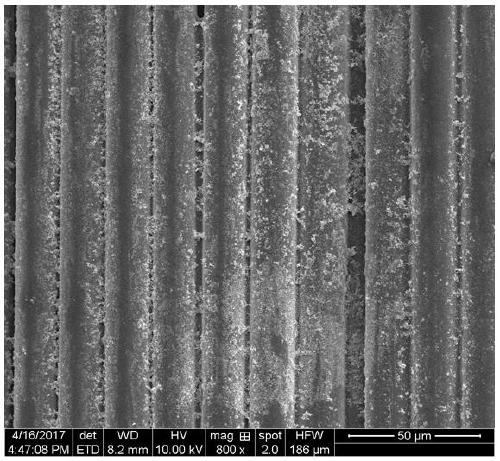

Image

Examples

Embodiment 1

[0026] Example 1 A method for preparing composite glass fibers with a nano-micron multi-level structure specifically includes the following preparation steps:

[0027] (1) Graphene oxide solids were prepared by the Hummers method reported in the literature, and a 0.5 mg / mL graphene oxide solution was prepared by means of an ultrasonic cell disruptor;

[0028] (2) Use a pipette gun to measure 500 μL of polydiallyldimethylammonium chloride into 200 mL of secondary water, and ultrasonically disperse it in the secondary water;

[0029] (3) Weigh 10 g of chopped glass fiber and add it to the solution obtained in step (2), place it in a water bath shaker at 20°C for 24 hours, and then wash it with secondary water;

[0030] (4) Add 150 mL of the graphene oxide solution prepared in step (1) to the product obtained in step (3), and react for 12 h in a shaking environment; wash the product with secondary water; place the washed product in After drying in a vacuum drying oven at 50°C, p...

Embodiment 2

[0035] Example 2 The preparation steps are the same as in Example 1, except that the KMnO described in step (5) 4 The solution concentration is 0.02 M, the Mn(CH 3 COO) 2 The solution concentration is 0.02 M.

Embodiment 3

[0036] Example 3 The preparation steps are the same as in Example 1, except that the Mn(CH 3 COO) 2 The solution dropping speed is 5 seconds / drop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com