Preparation method of conductive foam composite material for seepage electric simulation experiment

A conductive foam, electrothermal technology, applied in the analysis of materials, suspension and porous materials, permeability/surface area analysis, etc., to achieve the effect of eliminating electrolytic reaction, simple measurement method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) First, add the dried HDPE, EVA, and LDPE into the double-roller open mill, the component distribution ratio is HDPE:EVA:LDPE=50:40:10, and knead for 8 minutes, and then add the acetylene mixed with white oil Carbon black (CB) (filling dosage is 20phr), add in the mill, kneading 5min, finally add crosslinking agent DCP to be 0.5phr (phr is percentage content), foaming agent azodicarbonamide ( AC) is added in an amount of 6phr (the ratio of AC to Zn-St is 4:1) and is added to the open mill for 5 times, and then the tablet is removed, and the mixing temperature is 170°C.

[0029] (2) After the mixed sample is placed at room temperature for 24 hours, it is put into a foaming mold, and foamed on a flat vulcanizing machine at a molding temperature of 180°C and a molding pressure of 10Mpa, and the foaming time is 30 minutes.

[0030] (3) Put the prepared foam material into a vacuum drying oven, and heat balance for 3 hours under the condition of 100° C. under normal pressu...

Embodiment 2

[0034] (1) First, add the dried HDPE, EVA, and LDPE into the double-roller open mill, the component distribution ratio is HDPE:EVA:LDPE=50:40:10, and knead for 4 minutes, and then add the acetylene mixed with white oil Carbon black (CB) (filling dosage is 30phr), add in the mill, kneading 4min, finally the addition amount of crosslinking agent DCP is 0.5phr, foaming agent azodicarbonamide (AC) addition amount is 4phr ( The ratio of AC to Zn-St is 4:1) Add it into the open mill and pass it 4 times, then the next piece, the mixing temperature is 170°C.

[0035] (2) After the mixed sample is placed at room temperature for 24 hours, it is put into a foaming mold, and foamed on a flat vulcanizing machine at a molding temperature of 180°C and a molding pressure of 10Mpa, and the foaming time is 28 minutes.

[0036] (3) Put the prepared foam material into a vacuum drying oven, and heat balance for 2.5 hours under the condition of normal pressure of 100°C.

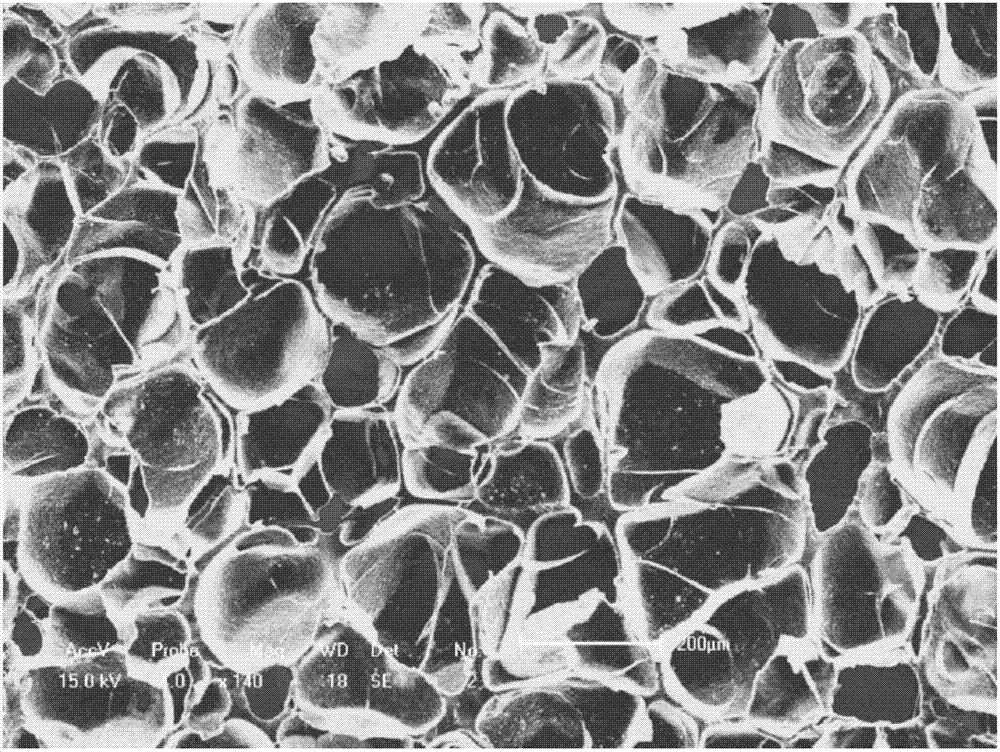

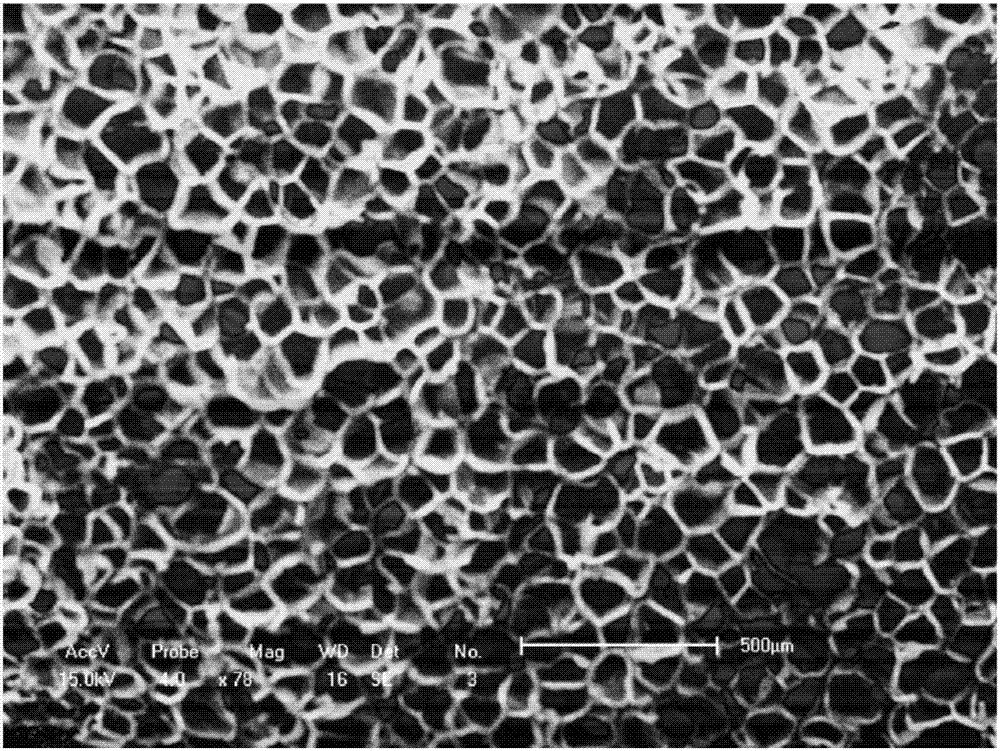

[0037] (4) The SEM photog...

Embodiment 3

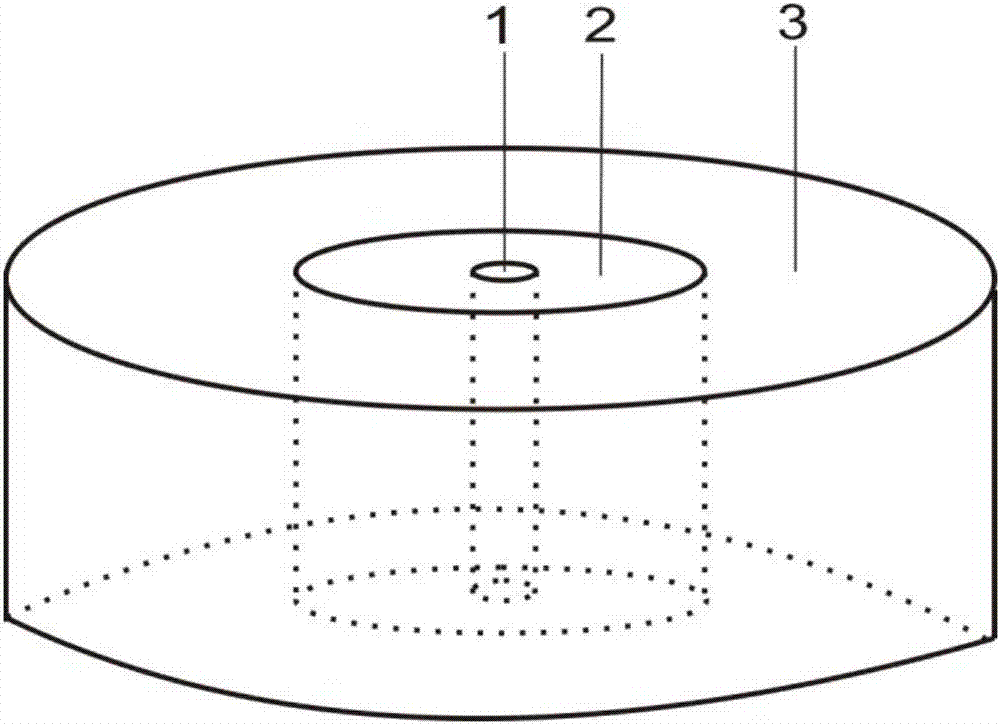

[0040] (1) The formed conductive foam composite material was put into a numerical control electric thermal cutting machine for electric thermal cutting treatment, and the material obtained in Example 1 was processed into a cylindrical ring with an outer radius of 0.5m and an inner radius of 0.3m. The material obtained in Example 2 was processed into a cylindrical ring with an outer radius of 0.3 m and an inner radius of 0.02 m.

[0041] (2) The two cylindrical rings made above are tightly nested together, and the inner diameter of the inner cylindrical ring is inserted into a 0.02m copper simulation well, such as image 3 As shown, among them, 1—copper simulated vertical well, 2—outer cylindrical ring, and 3—inner cylindrical ring, the electric simulation experiment of planar heterogeneous formation can be carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com