Sewage treatment filler

A sewage treatment and flame retardant technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of long service life and achieve long service life and film-hanging speed Fast and compact sewage treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

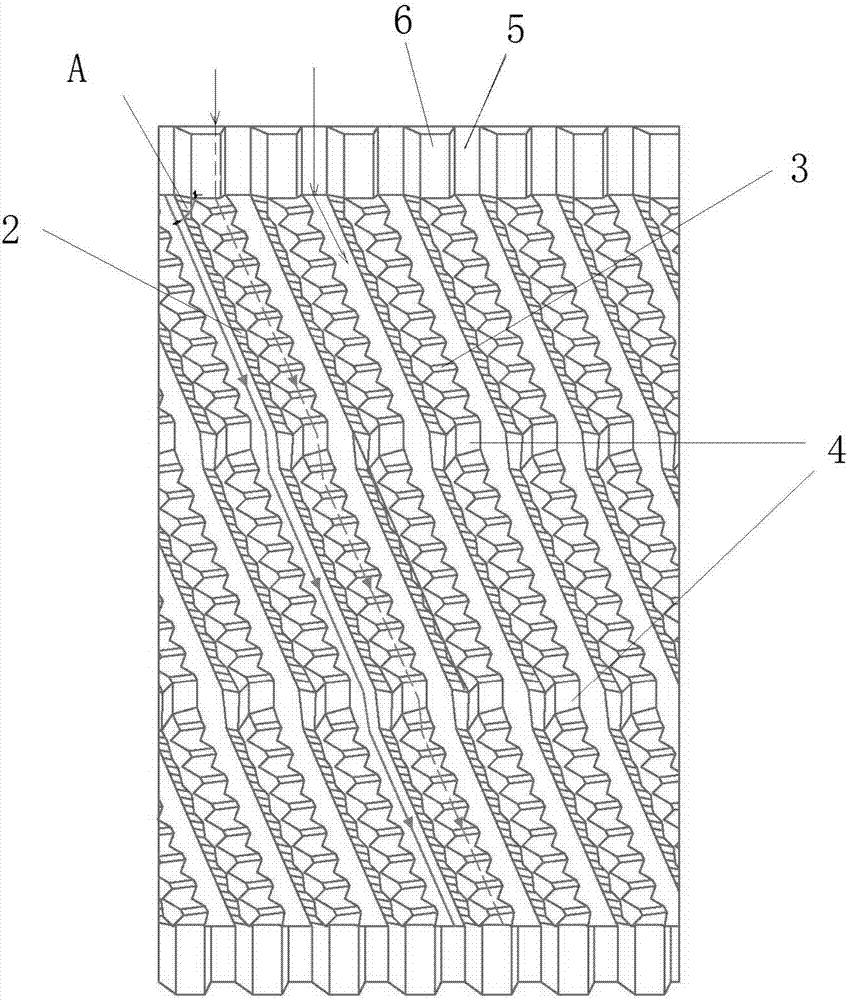

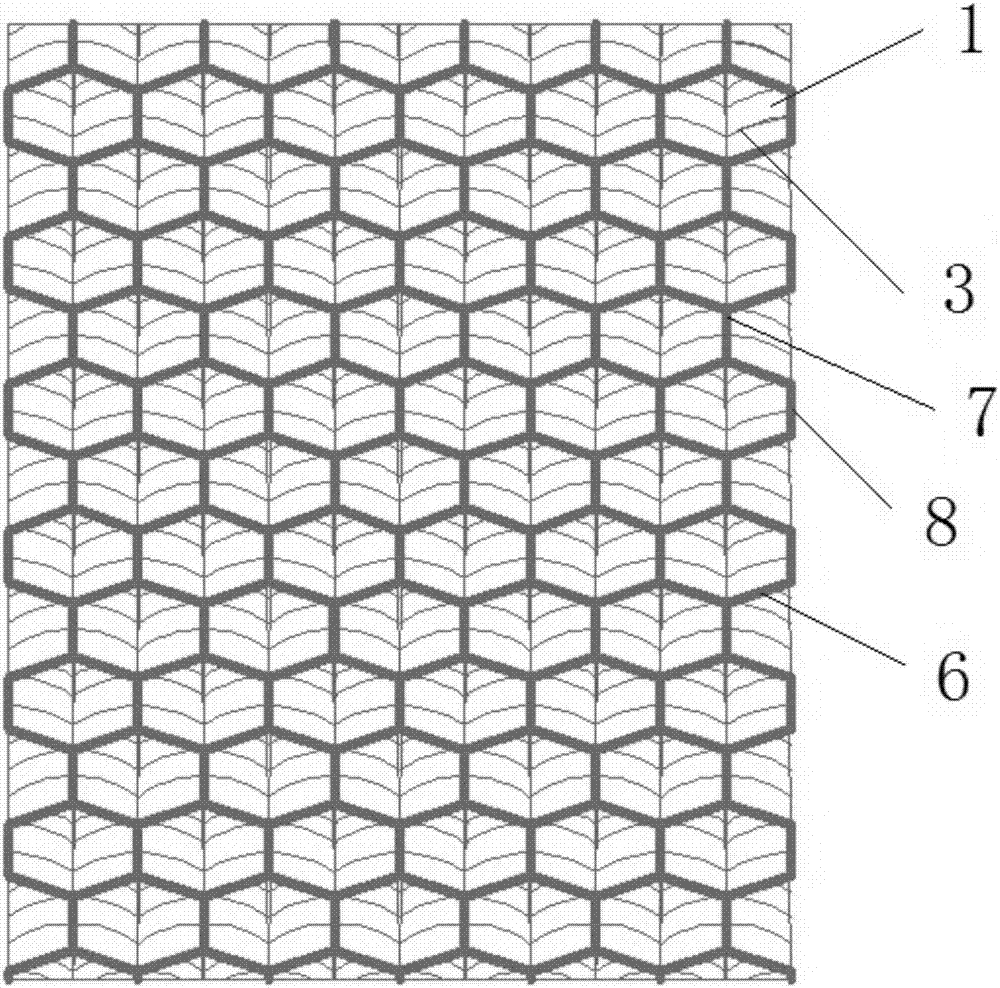

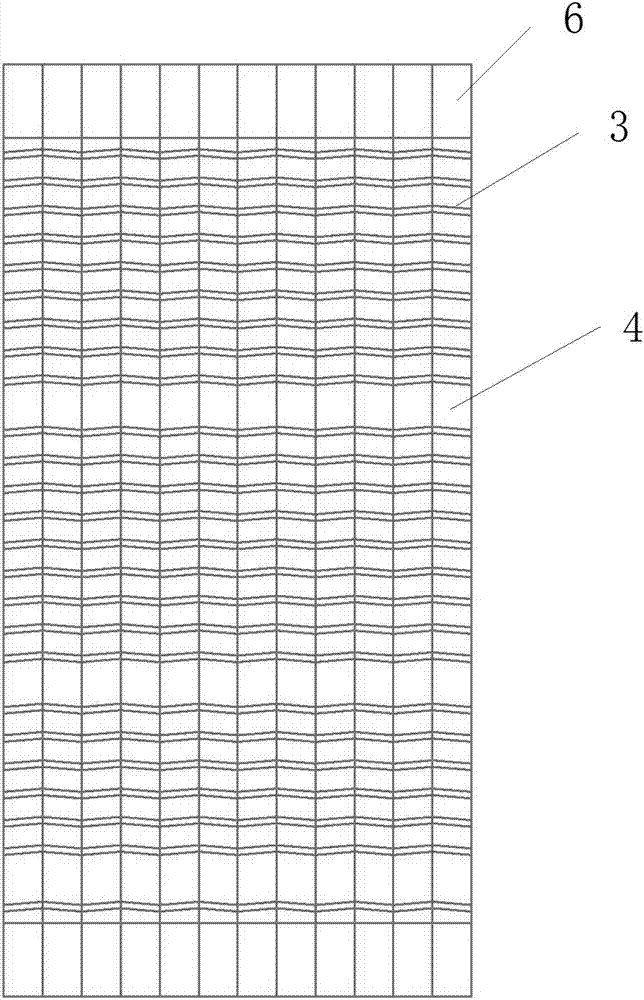

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] The sewage treatment filler of this embodiment includes: resin, dispersant, antioxidant, lubricant, light stabilizer, plasticizer, flame retardant, toughener and metal deactivator. Wherein, the resin is polypropylene, and the contact angle of polypropylene is less than 90°; the filler component is hydrated magnesium silicate; the dispersant is EBS; the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionic acid] pentaerythritol ester; lubricants include methyl palmitate and methyl stearate; light stabilizer is hindered amine light stabilizer 944; plasticizer is phthalates; flame retardant is decabromo Diphenyl ether; toughening agent is SBS; metal deactivator is 1,2 bis(2-hydroxyanisole) hydrazine. Antioxidants also include auxiliary antioxidants, auxiliary flame retardants, auxiliary antioxidants are tris(nonyl phe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com