Polyamide polycarbonate alloy material and preparation method and applications thereof

A polycarbonate and alloy material technology, applied in the field of polyamide polycarbonate alloy material and its preparation, can solve the problems of poor mechanical properties, poor dispersion, and weak interface adhesion of the blend system, and achieve good Dimensional stability and creep resistance, water absorption reduction, effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063]

[0064] The preparation method of above-mentioned polyamide polycarbonate alloy material comprises the steps:

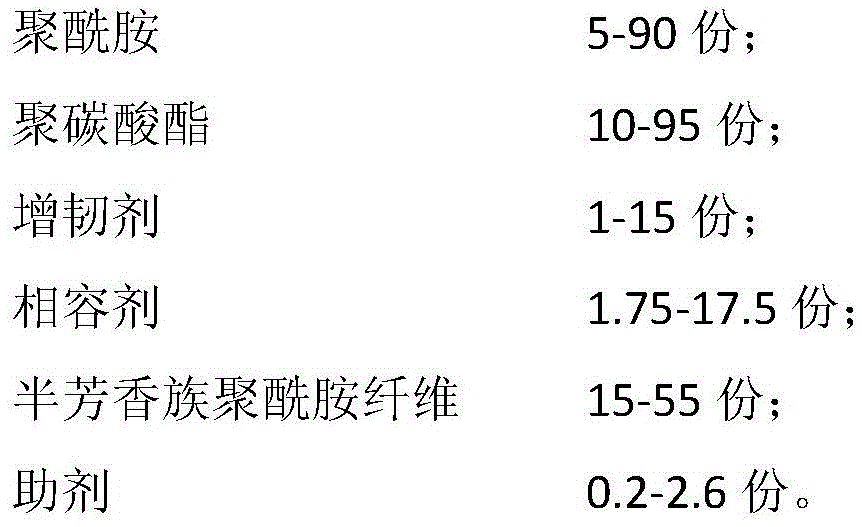

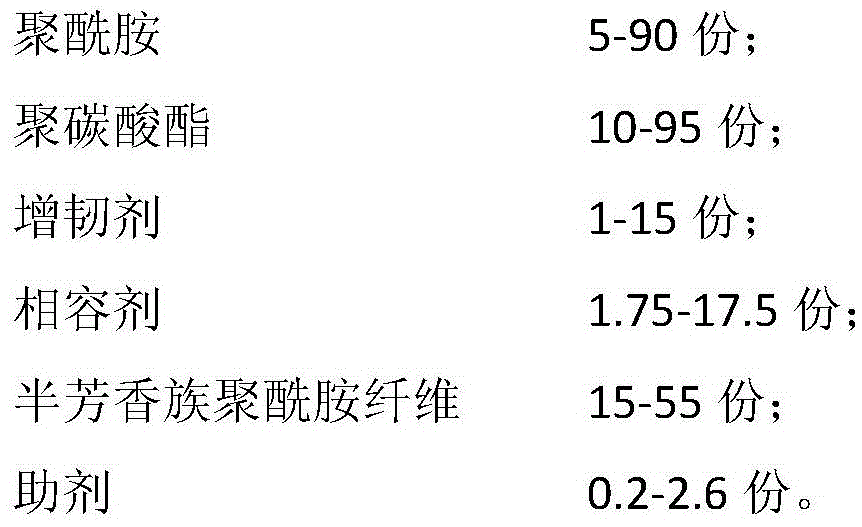

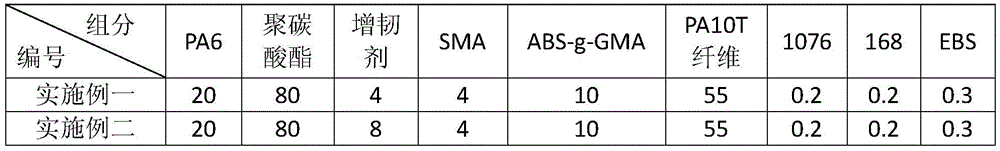

[0065] (1), 5-90 parts of dry polyamide, 10-95 parts of dry polycarbonate, 1-15 parts of dry toughening agent, 1.75-17.5 parts of dry compatibilizer and 0.2-2.6 parts of auxiliary Mix in a high-speed mixer for 5‐10min to obtain a premix;

[0066] (2) Add the premixed material into the main feeding hopper of the twin-screw extruder, add 15-55 parts of dry semi-aromatic polyamide fibers into the side feeding hopper of the twin-screw extruder, and pass through the twin-screw extruder. The extruder is extruded, stretched and pelletized to obtain the polyamide polycarbonate alloy material.

[0067] Wherein, in step (1), dry polyamide, dry polycarbonate, dry toughening agent and dry compatibilizer are respectively made of polyamide, polycarbonate, toughening agent and compatibilizer at 90‐ The obtained product was dried in an electric blast drying oven at 110°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com