Natural sausage casing processing method

A processing method, casing technology, applied in the field of radiation degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A processing method for natural casings: irradiate casings containing chloramphenicol after pickling, draining, and bagging the finished product at room temperature, and adopt the continuous irradiation method of automatic back and forth accumulation type suspension chains, and the electrical parameters of the speed of the suspension chains The irradiation time is 2-12h; the casing irradiation dose per bag is 2-9kGy; the unevenness of the same batch of products treated with the same irradiation dose is 1.1-1.4.

[0016] The casing is preferably one that does not contain sundries, has no peculiar smell, has no mildew, and has a good color.

[0017] The electrical parameter of the suspension chain speed is preferably 18Hz.

[0018] The unevenness of the same batch of products treated with the same radiation dose is preferably 1.2.

Embodiment 2

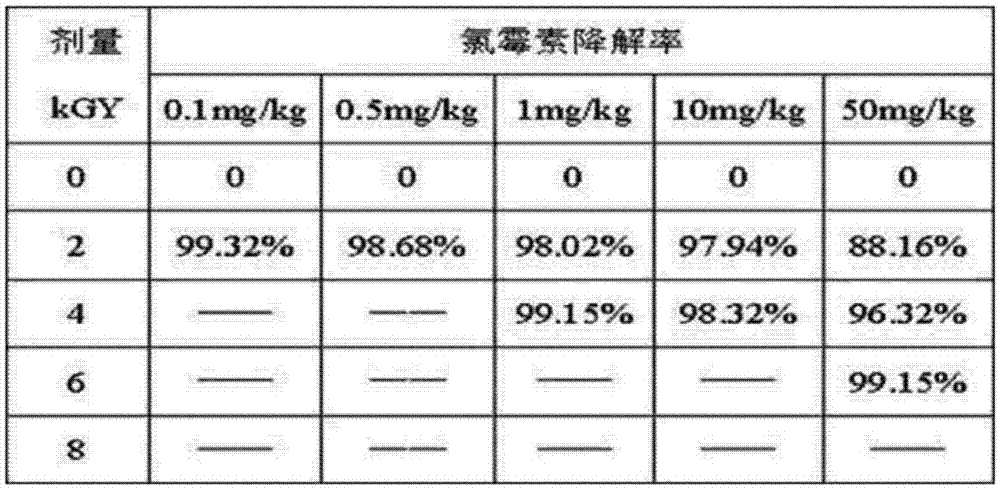

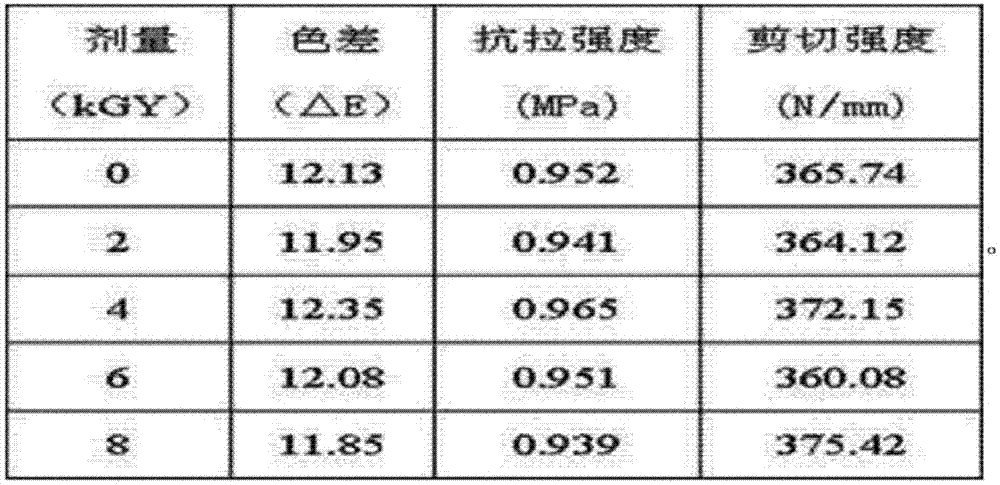

[0020] Select no sundries, no foreign matter, no moldy casings, do different irradiation doses (0kGy, 2kGy, 4kGy, 6kGy, 8kGy) for different initial contents of chloramphenicol in casings (0.1mg / kg, 0.5mg / kg, 1mg / kg, 10mg / kg, 50mg / kg), the irradiation parameters are set as follows: the continuous irradiation method of the hanging chain with automatic front and rear turning and storage is selected, the electric parameter of the hanging chain speed is 20Hz, and the samples with different irradiation doses The irradiation time is 0, 2.5, 5, 7.5, and 10 hours respectively; the irradiation dose of each bag of casing is 0kGy, 2kGy, 4kGy, 6kGy, 8kGy respectively; the unevenness of the same batch of products treated with the same irradiation dose is 1.2 .

[0021] Casing raw materials: provided by Rugao Baxin Casing Co., Ltd.;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com