Continuous synthetic method and synthetic equipment for 3,4-dichlorotrifluoromethyl benzene

A technology of dichlorobenzotrifluoride and p-chlorobenzotrifluoride, which is applied in the field of continuous synthesis of 3,4 dichlorobenzotrifluoride, can solve the technical problems of continuous production that cannot be overcome, the continuous production process cannot be industrialized, and the Time unevenness and other problems, to achieve the effect of long service life, high production capacity, closed production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

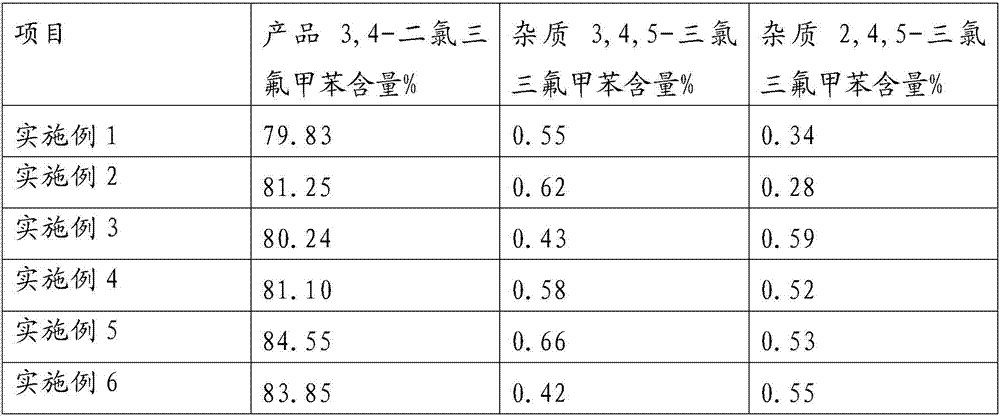

Embodiment 1

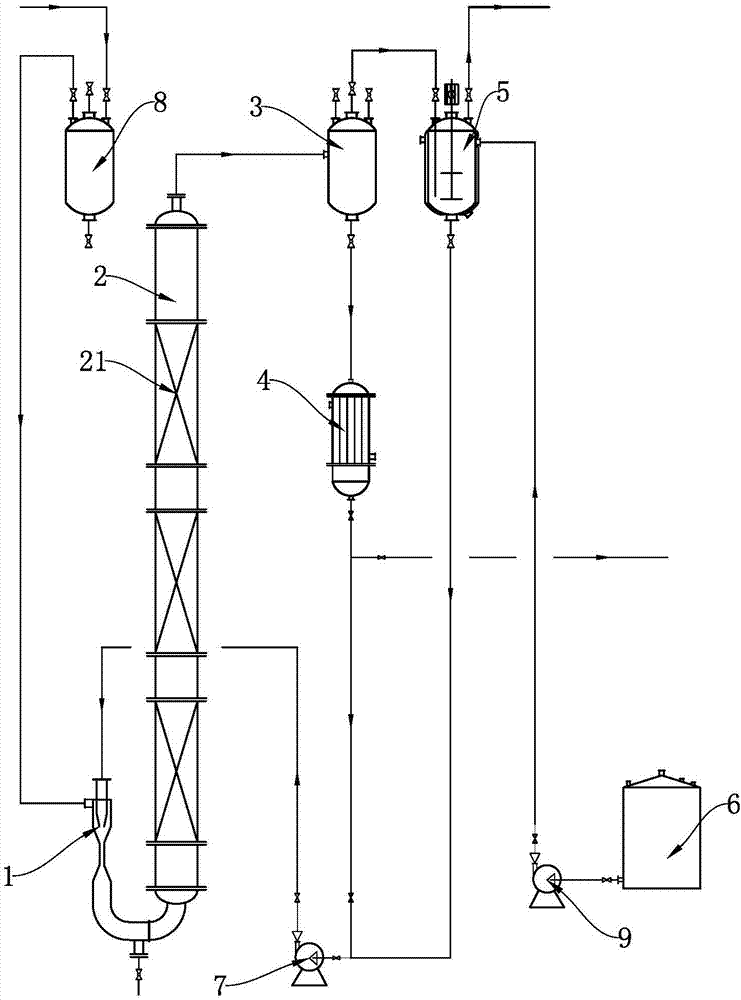

[0056] Using chlorine gas and p-chlorobenzotrifluoride as raw materials, the raw material chlorine gas and p-chlorobenzotrifluoride and the circulating material first enter the gas-liquid ejector, and are fully mixed through the gas-liquid ejector;

[0057] The mixed raw material enters the chlorination tower filled with iron shaving filler from the bottom to carry out continuous chlorination reaction, and the reactant is obtained from the top of the chlorination tower;

[0058] Part of the reactant obtained at the top of the chlorination tower is returned to the gas-liquid injector as a circulating material to continue the mixed reaction, and the rest is refined to obtain the product 3,4-dichlorotrifluorotoluene.

Embodiment 2

[0060] Using chlorine gas and p-chlorobenzotrifluoride as raw materials, the raw material chlorine gas and p-chlorobenzotrifluoride and the circulating material first enter the gas-liquid ejector, and are fully mixed through the gas-liquid ejector;

[0061] The mixed raw materials enter the chlorination tower filled with iron corrugated packing from the bottom to carry out continuous chlorination reaction, and the reactants are obtained from the top of the chlorination tower;

[0062] The reactant obtained at the top of the chlorination tower first undergoes gas-liquid separation, and the liquid-phase 3,4-dichlorobenzotrifluoride crude product after gas-liquid separation first passes through the heat exchanger to recover heat, and a part of it is returned to the gas-liquid injector as a circulating material to continue Mixed reaction, the rest is refined to obtain the product 3,4-dichlorobenzotrifluoride; the gas phase after gas-liquid separation uses raw material p-chlorobenzo...

Embodiment 3

[0064] Using chlorine gas and p-chlorobenzotrifluoride with a material ratio of 1:0.75 as raw materials, the raw material chlorine gas, p-chlorobenzotrifluoride and circulating materials first enter the gas-liquid ejector, and are fully mixed through the gas-liquid ejector;

[0065] The mixed raw materials enter the chlorination tower filled with iron Pall ring packing from the bottom to carry out continuous chlorination reaction. The temperature of the chlorination tower is controlled at 80-82°C, the chlorination reaction time is 32h, and the top of the chlorination tower gets the reaction Matter, the content of 3,4-dichlorobenzotrifluoride in the reactant is 70wt%;

[0066] The reactant obtained at the top of the chlorination tower first undergoes gas-liquid separation, and the liquid-phase 3,4-dichlorobenzotrifluoride crude product after gas-liquid separation first passes through the heat exchanger to recover heat, and a part of it is returned to the gas-liquid injector as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com