Biological fracturing fluid system as well as preparation and application thereof

A fracturing fluid and system technology, which is applied in the direction of production fluids, drilling compositions, chemical instruments and methods, etc., can solve the problems of residual glue blocking pores, incomplete gel breaking, etc., achieve high flowback rate, improve inability to The effect of breaking the glue or not breaking the glue completely, and breaking the glue completely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

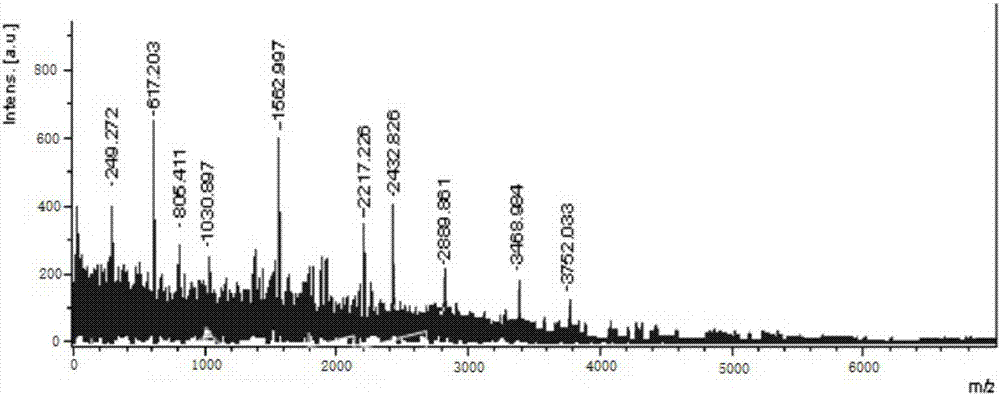

Image

Examples

Embodiment 1

[0034] The preparation of a new type of biological fracturing fluid system used in unconventional gas reservoirs is achieved in the following ways:

[0035] 1) Weigh 0.20 g of vegetable gum polymer (specifically hydroxypropyl guar gum) according to the weight ratio, and add 100 mL of water at a constant speed under high-speed stirring to prepare a guar gum base liquid.

[0036] 2) Add biological fungicide (specifically bacitracin) 0.02g, biological drainage aid (specifically surfactin) 0.025g, clay stabilizer (specifically KCl) 2g, biological enzyme breaker (specifically β-mannan) Enzyme) 30mg / L.

[0037] 3) Add a pH regulator to adjust the pH to 8.5-9.5.

[0038] 4) Adding a cross-linking agent for cross-linking, the cross-linking agent is a 1.5 wt% borax aqueous solution, the added amount is 5 mL, while gently stirring, the jelly used for fracturing can be obtained.

Embodiment 2

[0040] The preparation of a new type of biological fracturing fluid system used in unconventional gas reservoirs is achieved in the following ways:

[0041] 1) Weigh 0.20 g of vegetable gum polymer (specifically hydroxypropyl guar gum) according to the weight ratio, and add 100 mL of water at a constant speed under high-speed stirring to prepare a guar gum base liquid.

[0042] 2) Add biological fungicide (specifically polymyxin) 0.02g, biological drainage aid (specifically surfactin) 0.025g, clay stabilizer (specifically KCl) 2g, biological enzyme breaker (specifically β-mannan) Glycanase) 30mg / L.

[0043] 3) Add a pH regulator to adjust the pH to 8.5-9.5.

[0044] 4) Adding a cross-linking agent for cross-linking, the cross-linking agent is a 1.5 wt% borax aqueous solution, the added amount is 5 mL, while gently stirring, the jelly used for fracturing can be obtained.

Embodiment 3

[0046] The preparation of a new type of biological fracturing fluid system used in unconventional gas reservoirs is achieved in the following ways:

[0047] 1) Weigh 0.20 g of vegetable gum polymer (specifically carboxymethyl hydroxypropyl guar gum) according to the weight ratio, and add 100 mL of water at a constant speed under high-speed stirring to prepare a guar gum base liquid.

[0048] 2) Add biological fungicide (specifically polymyxin) 0.02g, biological drainage aid (specifically rhamnolipid) 0.003g, clay stabilizer (specifically KCl) 2g, biological enzyme breaker (specifically β-mannanase) 30mg / L.

[0049] 3) Add a pH regulator to adjust the pH to 8.5-9.5.

[0050] 4) Adding a cross-linking agent for cross-linking, the cross-linking agent is a 1.5 wt% borax aqueous solution, the added amount is 5 mL, while gently stirring, the jelly used for fracturing can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com