Skin-core composite fiber with nano fiber surface and preparation method thereof

A technology of nanofibers and composite fibers, applied in the direction of cellulose/protein conjugated artificial filaments, conjugated synthetic polymer artificial filaments, etc., can solve the problems of small specific surface area and inability to achieve good sensing, and achieve The effect of large specific surface area, excellent adsorption characteristics, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

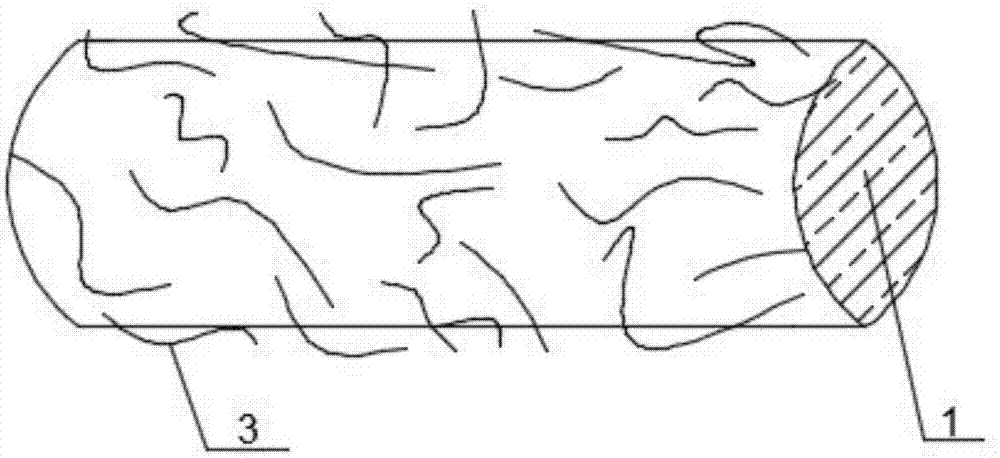

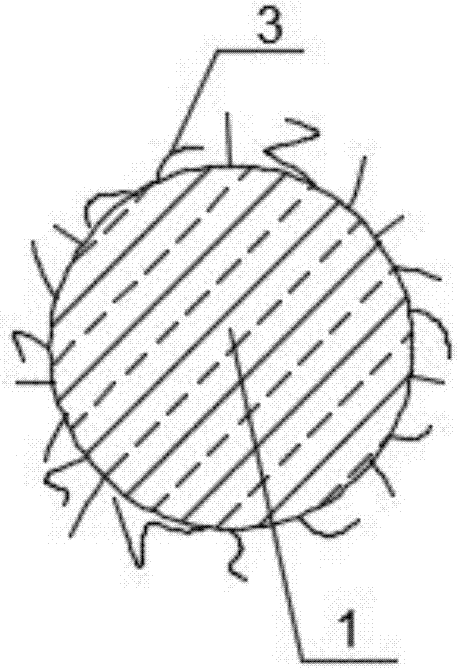

[0028] A preparation method of a skin-core composite fiber on the surface of a nanofiber, comprising the following steps:

[0029] 1) Preparation of skin-core composite fibers:

[0030] Weighing cortex raw materials: according to the mass ratio, weigh polypropylene 100g and cellulose acetate butyrate 900g, mix evenly to obtain cortex raw materials;

[0031] Core raw material: weigh 1000g of polypropylene;

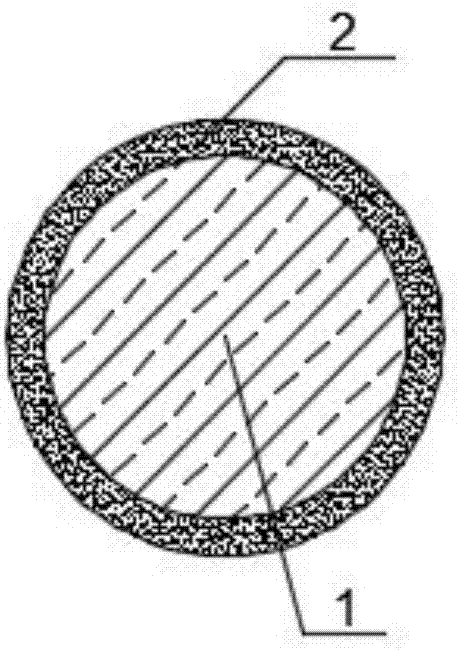

[0032] Put the cortex raw material and the core layer raw material into a two-component sheath-core composite spinning machine, melt spinning at 200°C, the cortex raw material is extruded by twin-screw in the two-component sheath-core composite spinning machine, and the core layer raw material is passed After the single-screw extrusion in the two-component sheath-core composite spinning machine, the sheath-core composite fiber (such as image 3 shown);

[0033] 2) Prepare the skin-core composite fiber on the surface of the nanofiber:

[0034] The sheath-core composite f...

Embodiment 2

[0037] A preparation method of a skin-core composite fiber on the surface of a nanofiber, comprising the following steps:

[0038] 1) Preparation of skin-core composite fibers:

[0039] Weighing cortex raw materials: weigh polyethylene 400g and cellulose acetate butyrate 600g according to mass ratio, and mix evenly to obtain cortex raw materials;

[0040] Core raw material: weigh polyethylene 4000g;

[0041] Put the cortex raw material and the core layer raw material into a two-component sheath-core composite spinning machine, melt spinning at 250°C, the cortex raw material is extruded by the twin-screw in the two-component sheath-core composite spinning machine, and the core layer raw material is passed through After the single-screw extrusion in the two-component sheath-core composite spinning machine, the sheath-core composite fiber (such as image 3 shown);

[0042] 2) Prepare the skin-core composite fiber on the surface of the nanofiber:

[0043] The sheath-core compo...

Embodiment 3

[0046] A preparation method of a skin-core composite fiber on the surface of a nanofiber, comprising the following steps:

[0047] 1) Preparation of skin-core composite fibers:

[0048] Weighing cortex raw materials: according to mass ratio, weigh 200g of polyester and 800g of cellulose acetate butyrate, mix evenly to obtain cortex raw materials;

[0049] Core material: weigh 250g of polyester;

[0050] Put the cortex raw material and the core layer raw material into a two-component sheath-core composite spinning machine, melt spinning at 300°C, the cortex raw material is extruded by twin-screws in the two-component sheath-core composite spinning machine, and the core layer raw material is passed through After the single-screw extrusion in the two-component sheath-core composite spinning machine, the sheath-core composite fiber (such as image 3 shown);

[0051] 2) Prepare the skin-core composite fiber on the surface of the nanofiber:

[0052] The sheath-core composite fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com