Superconductive graphene composite film line/strip and superconductive graphene composite cable

A graphene composite, superconducting thin film technology, applied in the field of power transmission system, can solve the problems of large superconductor, high consumption of constant conducting metal, unstable quench, etc., to improve mechanical strength, improve work stability and safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

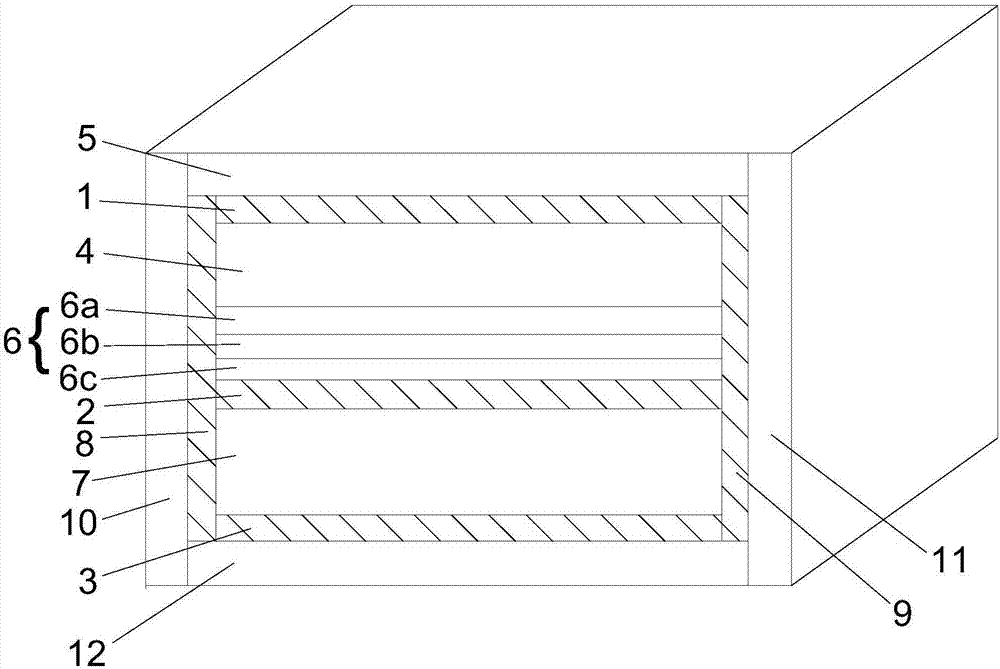

Embodiment 1

[0030] The structural sectional schematic diagram of single-sided superconducting graphene composite thin film line / strip of the present invention is as follows figure 1 Shown, the single-sided superconducting graphene composite thin film line / strip structural feature is: there is a superconducting thin film layer 4 on one side of the substrate layer 7; in the present embodiment 1: the first transverse graphene layer 1, the second The transverse graphene layer 2, the third transverse graphene layer 3, the longitudinal side graphene layer 8, and the longitudinal side graphene layer 9 all adopt graphene film; the superconducting thin film layer 4 adopts YBa 2 Cu 3 o 7-x (YBCO) coated conductor strip; the first transverse stabilizing layer 5, the second transverse stabilizing layer 12, the longitudinal side stabilizing layer 10, and the longitudinal side stabilizing layer 11 all adopt Cu plating layer; the substrate layer 7 adopts Ni alloy; buffer layer 6 consists of three laye...

Embodiment 2

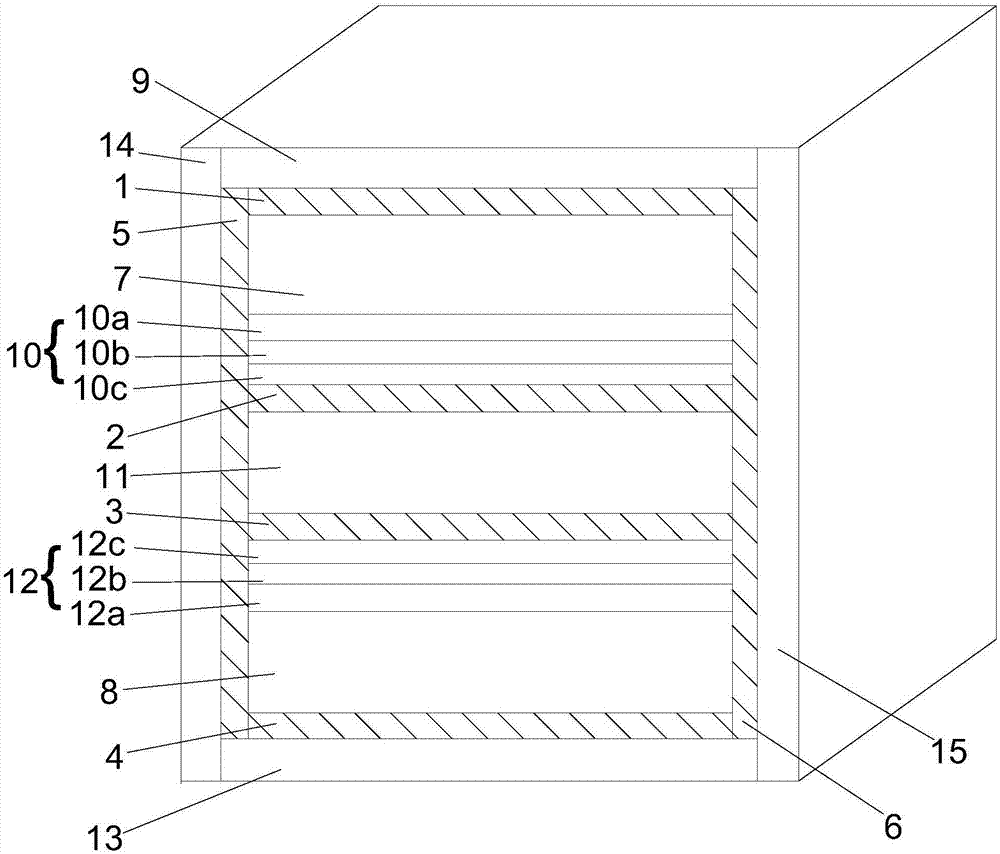

[0034] The structural sectional schematic diagram of double-sided superconducting graphene composite thin film line / strip of the present invention is as follows figure 2 As shown, the double-sided superconducting graphene composite thin film line / strip refers to: the upper side superconducting thin film layer 7 and the lower side superconducting thin film layer 8 are arranged in the substrate layer 11; in the present embodiment 2, the first transverse graphene Layer 1, the second transverse graphene layer 2, the third transverse graphene layer 3, the fourth transverse graphene layer 4, the longitudinal side graphene layer 5, and the longitudinal side graphene layer 6 all adopt superconducting graphene layers, namely: Graphene intercalation composite material layer; the superconducting thin film on the upper side, 7, and the superconducting thin film layer 8 on the lower side are all made of: GdBa 2 Cu 3 o 7-x (GBCO) superconducting tape; lateral stabilizing layer 9, lateral...

Embodiment 3

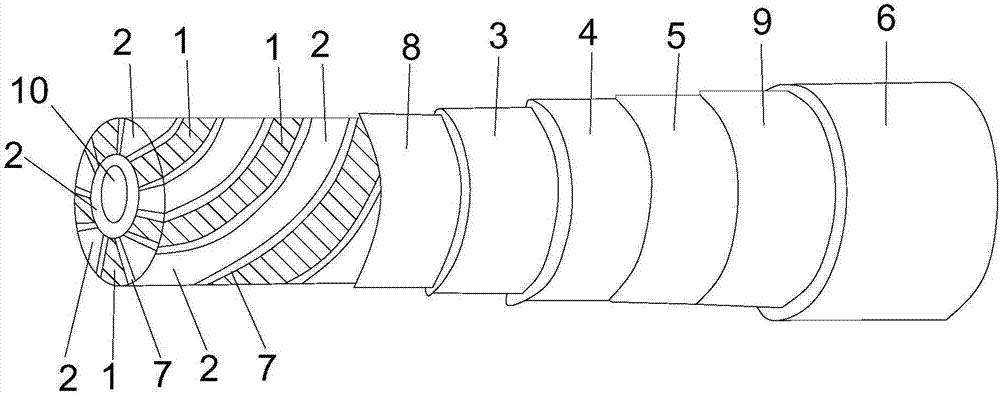

[0038] The structural representation of the five-convex-concave skeleton superconducting graphene composite cable of the present invention is as follows image 3 As shown, the structural cross-sectional schematic diagram of the superconducting graphene composite cable with five convex-concave skeletons is shown in Figure 4 Shown; superconducting graphene composite cable, including: superconducting graphene composite film line / strip 1, skeleton 2, graphene layer 7, graphene layer 8, heat insulation layer 3, electrical insulation layer 4, shielding layer 5, Graphene layer 9 and protective layer 6; superconducting graphene composite film line / strip 1 adopts double-sided superconducting graphene composite film line / strip, and its superconductor is: GdBa 2 Cu 3 o 7-x (GBCO) superconducting tape; skeleton 2 adopts: inner hollow and outer convex-concave skeleton, and its material is metal copper; the number of convex and concave shapes of inner hollow outer convex-concave skeleton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com