Preparation method of amino-functionalized porous CO2 adsorption material

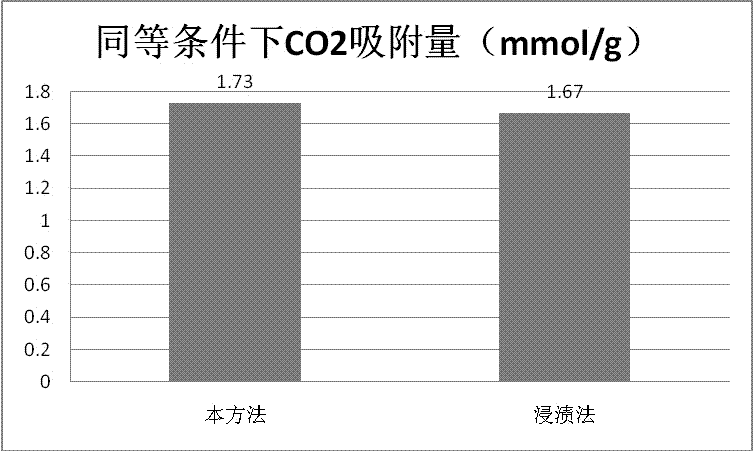

A technology of amino-functionalized and adsorbent materials, which is applied in the field of preparation of amino-functionalized porous adsorbent materials for CO2 adsorption, can solve the problems of affecting CO2 adsorption effect, destroying the pore structure of porous materials, and complicated preparation engineering, etc., and achieves easy industrial production, The effect of large adsorption capacity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

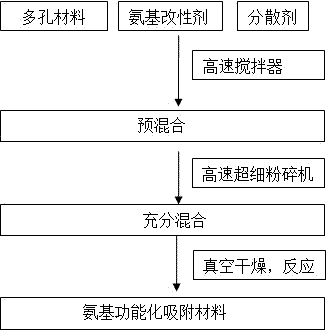

[0025] Embodiment 1: Prepare composite adsorbent according to the following steps

[0026] (1) Dry the attapulgite clay in an oven at 100°C for 4 hours; add 100 parts by weight of dried attapulgite clay, 10 parts by weight of ethylenediamine, and 10 parts by weight of silane coupling agent in a high-speed mixer KH550, mixing for 5 minutes, rotating speed 500rpm;

[0027] (2) Send the above-mentioned pre-mixed composite materials into a mechanical pulverizer for thorough mixing, the speed is 500r / min, and the pulverization time is 120min;

[0028] (3) Put the composite material obtained in step 2 into an oven at 60°C for 6 hours in vacuum to make the amino modifier fully react with the porous material to obtain amino-functionalized porous CO 2 Adsorbent material.

Embodiment 2

[0029] Embodiment 2: prepare composite adsorbent according to the following steps

[0030] (1) Dry the zeolite molecular sieve in an oven at 90°C for 5 hours; add 100 parts by weight of dried zeolite molecular sieve SAPO-34, 50 parts by weight of diethylenetriamine, and 4 parts by weight of polymethyl The acrylate was mixed for 10 minutes at a speed of 300 rpm, and the stirring was stopped for 3 minutes every 5 minutes to prevent frictional heat from causing the material to stick;

[0031] (2) Send the above-mentioned pre-mixed composite materials into the jet mill for thorough mixing, the speed is 1200 r / min, and the grinding time is 50 minutes;

[0032] (3) Put the composite material obtained in step 2 into a vacuum oven at 70°C for 5 hours to fully react the amino modifier with the porous material to obtain amino-functionalized porous CO 2 Adsorbent material.

Embodiment 3

[0033] Embodiment 3: prepare composite adsorbent according to the following steps

[0034] (1) Dry the silica in an oven at 80°C for 6 hours; add 100 parts by weight of dried silica, 60 parts by weight of triethylenetetramine, and 5 parts by weight of titanate in a high-speed mixer Coupling agent, mix for 20 minutes, rotate at 50rpm, and stop for 3 minutes every 5 minutes to prevent friction and heat from sticking the material;

[0035] (2) Send the above-mentioned pre-mixed composite materials into an ultrasonic pulverizer for thorough mixing, the speed is 2000 r / min, and the pulverization time is 30 minutes;

[0036] (3) Put the composite material obtained in step 2 into an oven at 80°C for 4 hours in vacuum to make the coupling agent fully react with silica to obtain amino-functionalized porous CO 2 Adsorbent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com