Nanostructure material assembled by carbon nanotubes prepared based on low-temperature pyrolysis of metal-organic framework compounds, preparation method of nanostructure material and application

A metal-organic framework and carbon nanotube technology, applied in the direction of carbon nanotubes, nanotechnology for materials and surface science, nanocarbon, etc., can solve problems such as simple structure and limited high-temperature pyrolysis, and achieve simple and efficient methods. The effect of cheap raw materials, simple process and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

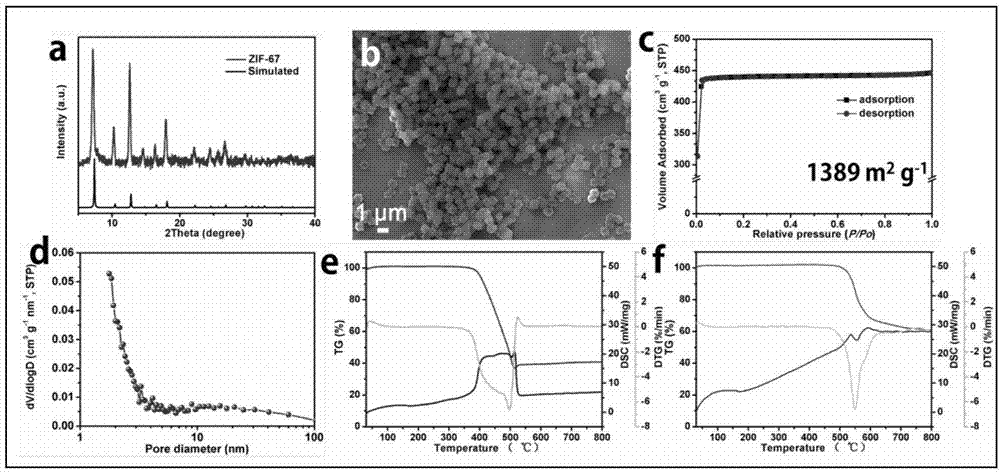

[0040] 1) Dissolve 1 mmol of cobalt nitrate hexahydrate in 25 mL of methanol; in addition, weigh 4 mmol of 2-methylimidazole and dissolve in 25 mL of methanol, then pour into the former pink solution, and stir the mixed solution for 24 h. Centrifuge and wash three times with methanol solution to obtain a purple solid, which is the metal organic framework compound Co-ZIF-67 powder;

[0041] 2) Place the powder obtained in step 1) in an oven at 80°C to dry for 5h;

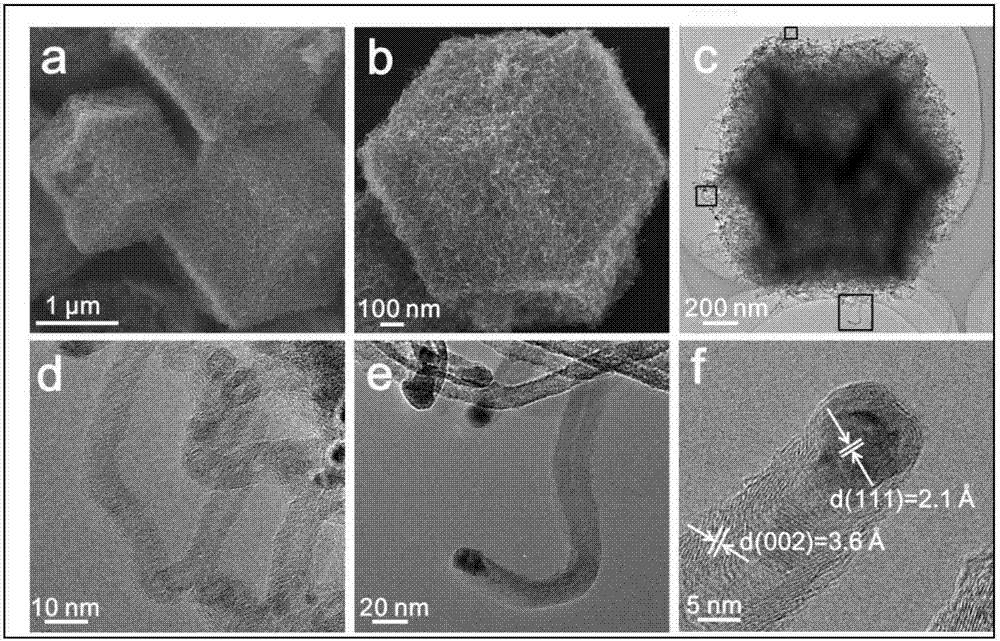

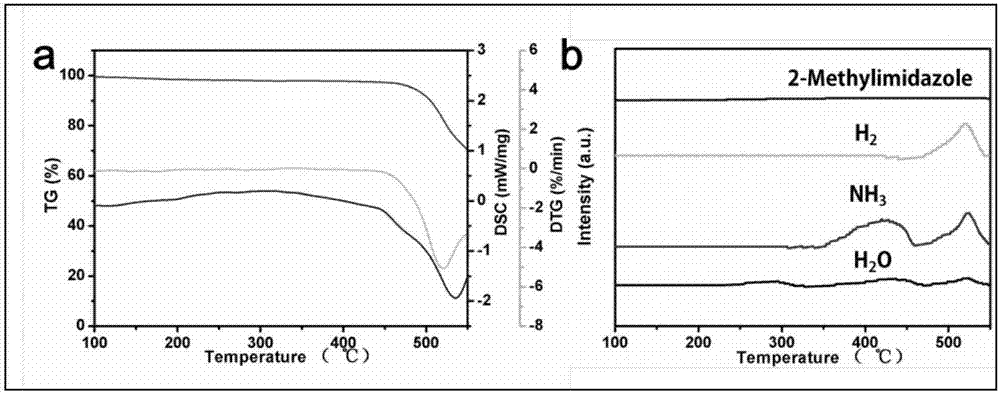

[0042] 3) The metal-organic framework compound Co-ZIF-67 powder obtained in step 2) was placed under an argon atmosphere at a temperature of 2 °C for min -1 The hollow dodecahedral structure material (product) assembled with nitrogen-doped carbon nanotubes can be obtained by slowly heating up to 435° C. and holding the temperature for 8 hours.

[0043] The formation process of the hollow dodecahedral structure assembled by nitrogen-doped carbon nanotubes of the present invention: such as figure 1 As shown, the form...

Embodiment 2

[0051] 1) Weigh 2mmol of cobalt nitrate hexahydrate and 0.3mmol of ferric nitrate nonahydrate and dissolve them in 20mL of N,N-dimethylformamide; The methylformamide solution was mixed, fully stirred, transferred to a 50 mL reaction kettle, and kept at 180 °C for 24 h. The metal organic framework compound Co, Fe-ZIF powder was obtained by centrifuging and washing three times with methanol solution;

[0052] 2) Place the powder obtained in step 1) in an oven at 80°C to dry for 5h;

[0053] 3) The metal-organic framework compound Co, Fe-ZIF powder obtained in step 2) was placed in an argon atmosphere at a temperature of 2 °C min -1 The microsphere structure material (product) assembled with carbon nanotubes can be obtained by slowly heating up to 435° C. and holding the temperature for 8 hours.

[0054] The microsphere structure material assembled with the carbon nanotubes obtained in this example, such as Figure 14As shown, the precursor has a relatively uniform morphology ...

Embodiment 3

[0056] 1) take by weighing the nickel nitrate hexahydrate of 1mmol and be dissolved in the methanol of 20mL; in addition take by weighing the 2-methylimidazole of 4mmol also be dissolved in the methanol of 20mL, pour into former solution then, fully stir, transfer to 50mL reactor Incubate at 140°C for 12h. The metal organic framework compound Ni-ZIF powder was obtained by centrifuging and washing three times with methanol solution;

[0057] 2) Place the powder obtained in step 1) in an oven at 80°C to dry for 5h;

[0058] 3) The metal-organic framework compound Ni-ZIF powder obtained in step 2) was placed under an argon atmosphere at a temperature of 2 °C for min -1 The microsphere structure material (product) assembled with carbon nanotubes can be obtained by slowly heating up to 435° C. and holding the temperature for 8 hours.

[0059] The microsphere structure material assembled with the carbon nanotubes obtained in this example, such as Figure 15 As shown, the precurso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com