Paper for photocatalytic cracking of water, a preparing method thereof and applications of the paper

A photocatalytic and nano-paper technology, applied in the field of photocatalytic materials, can solve the problems of high hydrogen energy preparation cost, difficult recovery of photocatalysts, and difficulty in wide application, achieving great application value, enhanced performance of photocatalytic splitting water for hydrogen production, Apply convenient and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

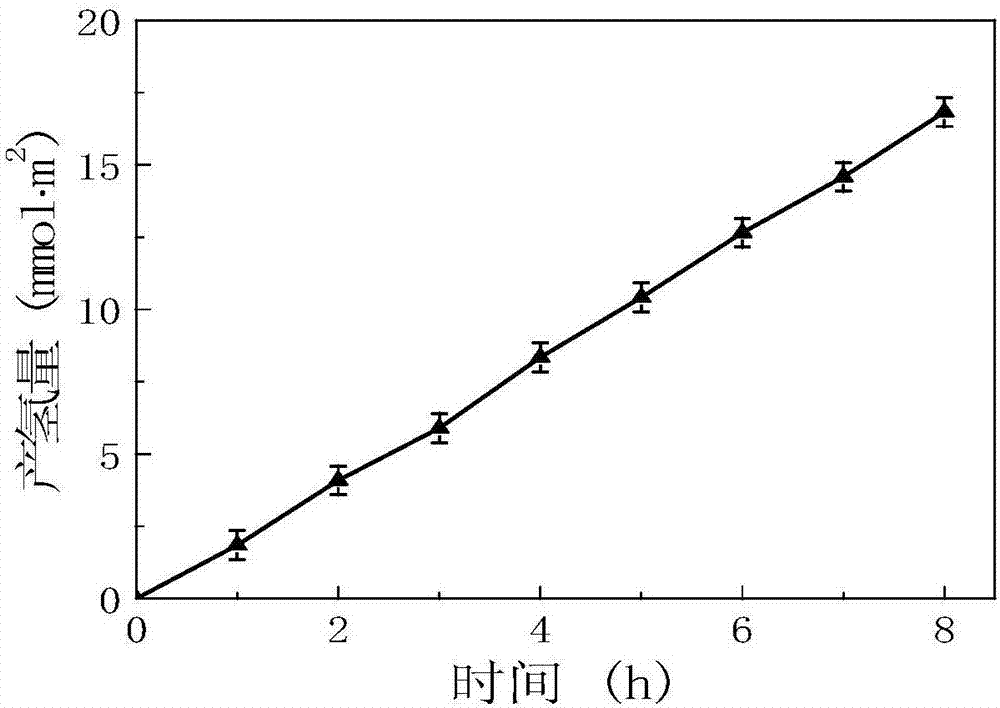

Embodiment 1

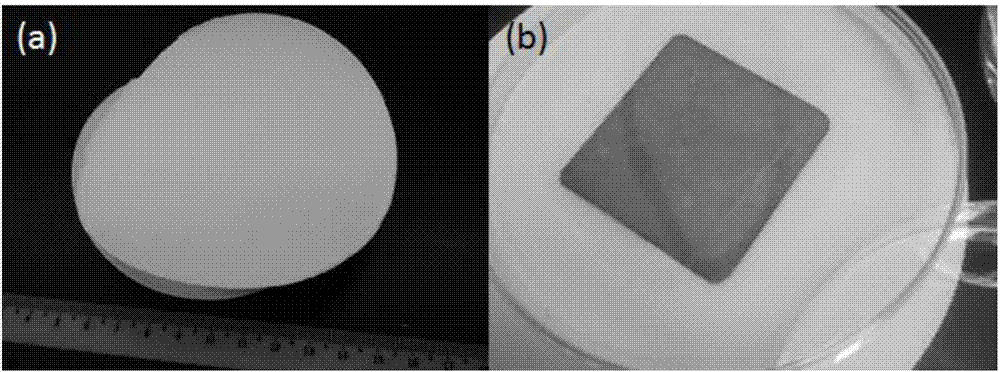

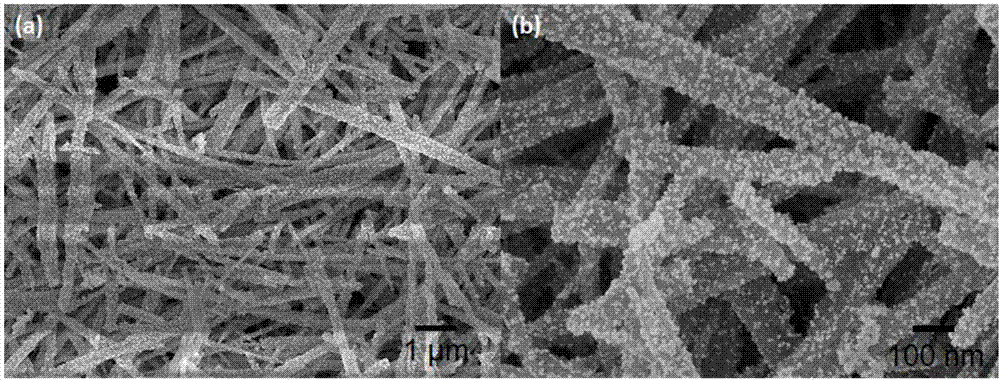

[0022] ①Weigh one-dimensional titanium dioxide nanobelts and disperse them in deionized water, ultrasonically disperse and magnetically stir for 20±5 minutes each to obtain a titanium dioxide dispersion with a concentration of 0.5g / L; then slowly drop a hydrogen chloride solution with a concentration of 0.15mol / L Add it to the prepared titanium dioxide dispersion to adjust the pH to 2; pour the adjusted pH titanium dioxide dispersion into the Buchner funnel suction filtration device, obtain a filter cake layer with a certain thickness after suction filtration, and rinse it with water until Neutral, then take out the filter cake, dry at 50±10°C for 12-18 hours, remove the filter paper to get TiO with a thickness range of 0.1mm 2 nano paper;

[0023] ②Cut the TiO obtained in step ① of size setting 2 The nano paper is soaked in ethanol solution with a volume concentration of 2% tetrabutyl titanate, soaked for 0.5-5 hours, taken out and dried naturally to obtain hydrophilic modif...

Embodiment 2

[0031]① Weigh one-dimensional titanium dioxide nanowires and disperse them in deionized water, ultrasonically disperse and magnetically stir for 20±5 minutes each to prepare a titanium dioxide dispersion with a concentration of 0.1g / L; then slowly add a hydrogen chloride solution with a concentration of 0.3mol / L dropwise Into the obtained titanium dioxide dispersion, adjust the pH to 1.5; pour the adjusted pH titanium dioxide dispersion into a Buchner funnel suction filtration device for suction filtration to obtain a filter cake layer of a certain thickness, wash it with water until neutral, and then take out Filter cake, dry at 50±10°C for 12-18 hours, remove the filter paper to obtain TiO with a thickness range of 0.1mm 2 nano paper;

[0032] ②Cut and set the size step (①Obtained TiO 2 The nano paper is soaked in ethanol solution with a volume concentration of 1% tetrabutyl titanate, soaked for 0.5-5 hours, taken out and dried naturally to obtain hydrophilic modified TiO ...

Embodiment 3

[0036] ①Weigh one-dimensional titanium dioxide nanotubes and disperse them in deionized water, ultrasonically disperse and magnetically stir for 20±5min respectively to prepare a titanium dioxide dispersion with a concentration of 0.2g / L; then slowly add hydrogen chloride solution with a concentration of 0.4mol / L Into the obtained titanium dioxide dispersion, adjust the pH to 3; pour the adjusted pH titanium dioxide dispersion into a Buchner funnel suction filtration device for suction filtration to obtain a filter cake layer of a certain thickness, wash it with water until neutral, and then take out Filter cake, dry at 50±10°C for 12-18 hours, remove the filter paper to obtain TiO with a thickness range of 0.2mm 2 nano paper;

[0037] ②Cut the TiO obtained in step ① of size setting 2 The nano paper is soaked in ethanol solution with a volume concentration of 4% tetrabutyl titanate, soaked for 0.5-5 hours, taken out and dried naturally to obtain hydrophilic modified TiO 2 Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com