Papermaking wastewater treatment agent

A technology for papermaking wastewater and treatment agent, which is applied in processing wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex process, poor flocculation and adsorption effect, low flocculation characteristics, etc. Good treatment effect, high efficiency, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

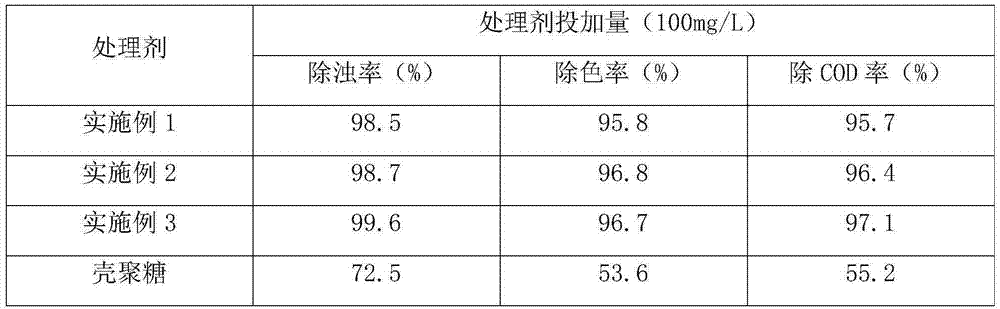

Examples

Embodiment 1

[0015] A papermaking wastewater treatment agent, comprising raw materials of the following weight: 4kg of bentonite, 9kg of diatomite, 10kg of aluminum hydroxide gel, 3kg of sodium humate, 10kg of sodium polyacrylate, 5kg of polysorbate, 5kg of aluminum sulfate, and 4kg of nano-titanium dioxide , activated carbon 5kg, sodium carbonate 1kg and water 100L.

[0016] A preparation method of a papermaking wastewater treatment agent, comprising the steps of: taking raw materials of the following weight: 4kg of bentonite, 9kg of diatomaceous earth, 10kg of aluminum hydroxide gel, 3kg of sodium humate, 10kg of sodium polyacrylate, 5kg of polysorbate, 5kg of aluminum sulfate, 4kg of nano-titanium dioxide, 5kg of activated carbon, and 1kg of sodium carbonate are uniformly mixed, pulverized, added with 100L of water, ball milled, dried, and passed through a 100-200 mesh sieve to obtain the papermaking wastewater treatment agent.

Embodiment 2

[0018] A papermaking wastewater treatment agent, comprising the following raw materials: 8kg of bentonite, 6kg of diatomite, 7kg of aluminum hydroxide gel, 6kg of sodium humate, 8kg of sodium polyacrylate, 7kg of polysorbate, 3kg of aluminum sulfate, and 8kg of nano-titanium dioxide , activated carbon 3kg, sodium carbonate 3kg and water 85L.

[0019] The preparation method is the same as that of Example 1, except that the dosage of each component is different.

Embodiment 3

[0021] A papermaking wastewater treatment agent, comprising the following raw materials in weight: 12kg of bentonite, 3kg of diatomite, 5kg of aluminum hydroxide gel, 9kg of sodium humate, 5kg of sodium polyacrylate, 10kg of polysorbate, 1kg of aluminum sulfate, and 12kg of nano-titanium dioxide , activated carbon 1kg, sodium carbonate 5kg and water 70L.

[0022] The preparation method is the same as that of Example 1, except that the dosage of each component is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com