Monocrystal lithium-rich manganese-based multi-component positive electrode material and preparation method

A lithium-rich manganese-based, cathode material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low tap density, limiting the practical application of lithium-rich manganese-based multi-component materials, and unfavorable electrode sheet rolling and preparation. , to achieve the effect of easy control, suitable for large-scale production and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

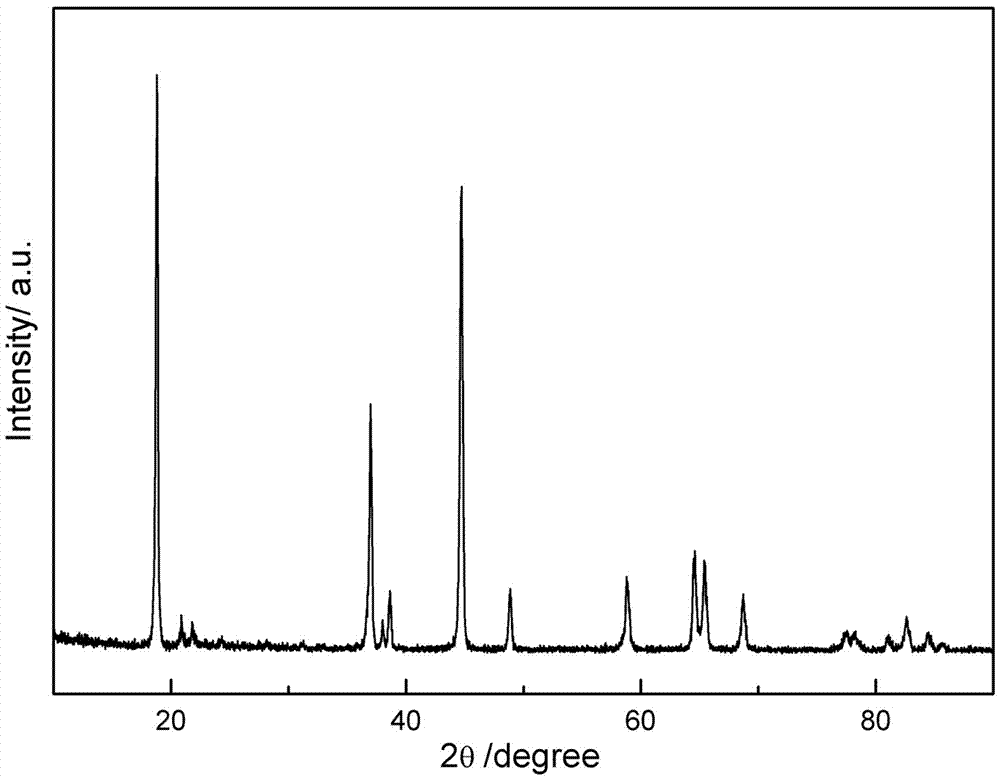

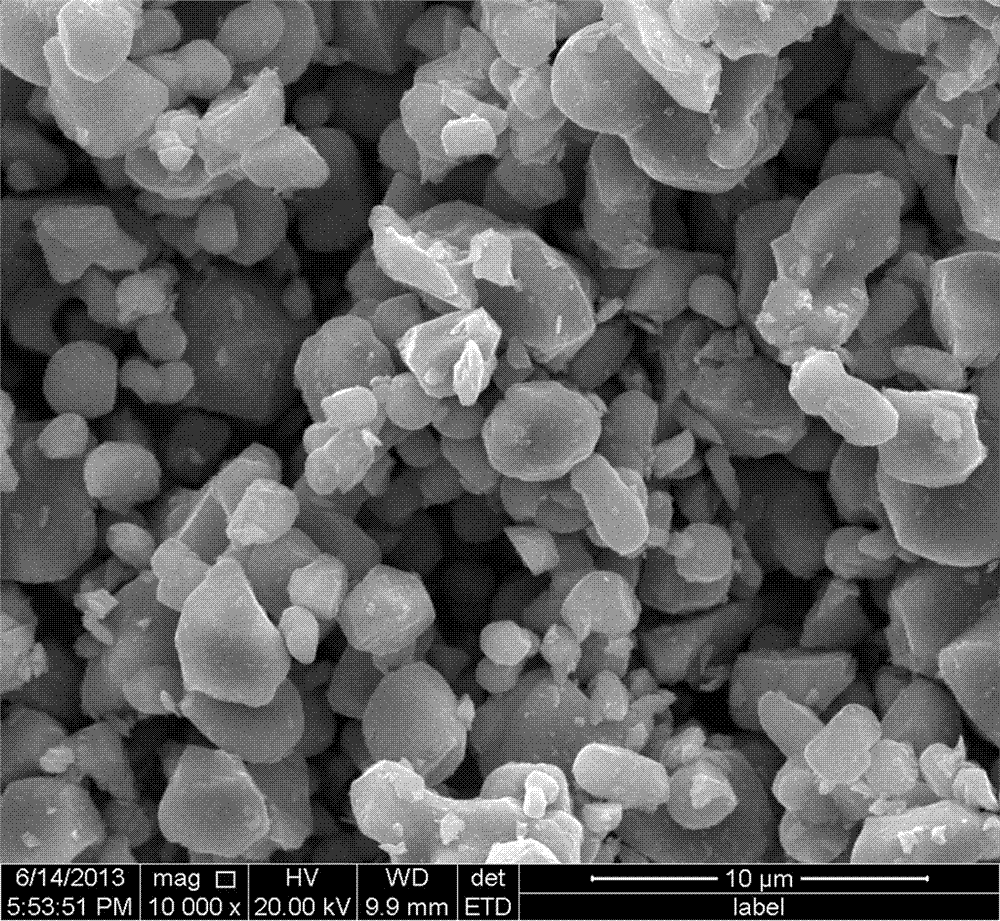

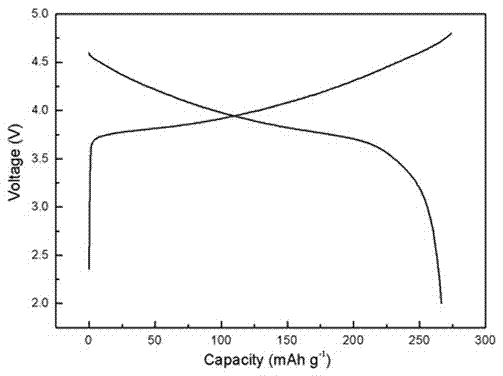

[0022] Prepare sample 0.5Li 2 MnO 3 ·0.5LiNi 0.33 Mn 0.33 Co 0.33 O 2 . Dissolve nickel sulfate, manganese sulfate and cobalt sulfate in deionized water according to the stoichiometric ratio to form solution A with a metal ion concentration of 0.5 mol / L; configure a mixed solution B of sodium carbonate and sodium bicarbonate, in which sodium carbonate and carbonic acid The molar ratio of sodium hydrogen is 1:1, and the concentration of carbonate ions is 0.5mol / L; the solutions A and B are added dropwise to the beaker with a constant flow pump and continuously stirred at 50°C. The pH value is adjusted by ammonia water and maintained at 7.5. After the reaction is complete, the precipitate is aged for 6 hours at 50°C; the obtained precipitate is filtered and washed with deionized water several times, and dried in an oven at 100°C to obtain a carbonate precursor; weigh 1.05 times the stoichiometric ratio of hydroxide Lithium and carbonate precursors were crushed and ball milled for...

Embodiment 2

[0024] Prepare sample 0.5Li 2 MnO 3 ·0.5LiNi 0.45 Mn 0.45 Mg 0.1 O 2 . Weigh nickel acetate, manganese acetate and magnesium acetate according to the stoichiometric ratio and dissolve them in deionized water to form a solution A with a metal ion concentration of 2.0 mol / L; configure a mixed solution B of sodium carbonate and sodium bicarbonate, in which sodium carbonate and carbonic acid The molar ratio of sodium hydrogen is 3:1, and the concentration of carbonate ion is 2.0mol / L; the solutions A and B are added dropwise to the beaker with a constant flow pump and continuously stirred at 40°C. The pH value is adjusted and maintained at 8.0 with ammonia water. After the reaction is complete, the precipitate is aged for 24 hours at 40°C; the obtained precipitate is filtered and washed with deionized water several times, and dried in an oven at 100°C to obtain a carbonate precursor; weigh 1.1 times the stoichiometric ratio of lithium nitrate Crushing and ball milling with carbonat...

Embodiment 3

[0026] Prepare sample 0.4Li 2 MnO 3 ·0.6LiNi 0.32 Mn 0.32 Co 0.32 Al 0.03 O 2 . Weigh nickel nitrate, manganese nitrate, cobalt nitrate and aluminum nitrate according to the stoichiometric ratio and dissolve them in deionized water to form solution A with a metal ion concentration of 1.5 mol / L; configure a mixed solution B of sodium carbonate and sodium bicarbonate, in which carbonic acid The molar ratio of sodium to sodium bicarbonate is 2:1, and the concentration of carbonate ions is 1.5mol / L; use a constant flow pump to drop solutions A and B into the beaker and stir continuously at 55°C. Use ammonia to adjust the pH and maintain At 8.0, after the reaction is complete, the precipitate is aged for 10 hours at 55°C; the obtained precipitate is filtered and washed with deionized water several times, and dried in an oven at 100°C to obtain a carbonate precursor; the stoichiometric ratio is 1.08 times Lithium carbonate and carbonate precursor are crushed and ball milled for 1.0h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com