Bamboo leaf ferment and preparation method thereof

A technology of bamboo leaves and enzymes, applied in the field of enzymes, to achieve the effects of simple preparation methods, good fermentation effects, and no additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

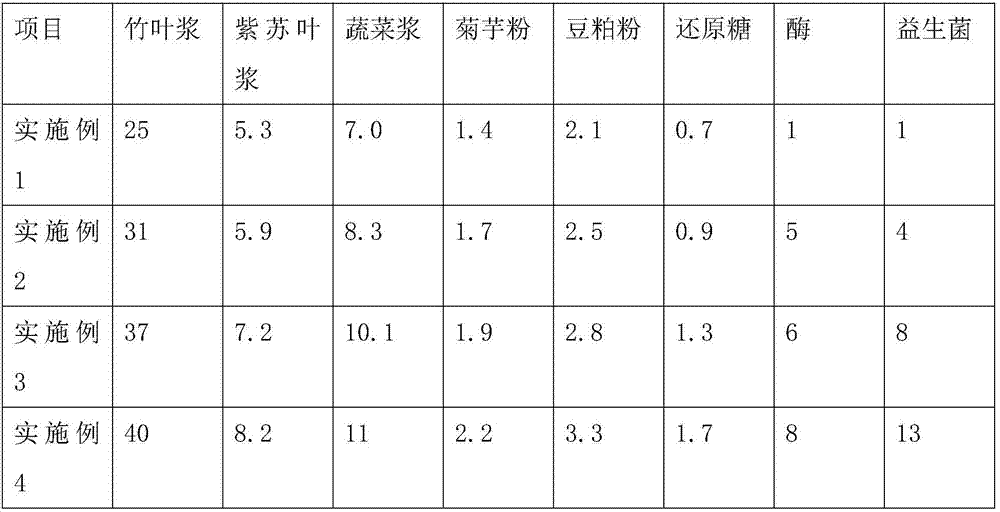

Examples

Embodiment 1

[0036] A kind of bamboo leaf enzyme, by weight:

[0037] Bamboo leaf pulp 25 Perilla leaf pulp 5.3 Cabbage and carrot pulp 7.0 Jerusalem artichoke powder 1.4 Soybean meal powder 2.1 Fructose 0.7 Cellulase 1 Brewer's yeast 1;

[0038] The preparation method of this bamboo leaf ferment comprises the following steps:

[0039] 1) cleaning, drying, crushing and beating bamboo leaves to obtain bamboo leaf pulp;

[0040] 2) adding fructose, Jerusalem artichoke powder, soybean meal powder, perilla leaf pulp, cabbage and carrot pulp to the bamboo leaf pulp, stirring evenly to obtain a mixed pulp;

[0041] 3) adjusting the pH of the mixed slurry to 4.0;

[0042] 4) Put the mixed pulp into the fermentation container, treat it with 400W ultrasonic wave for 30 minutes, seal it immediately, and carry out the first stage of anaerobic fermentation at 40°C for 5 days; lower the temperature to 33°C, and adjust the pH with lemon juice to 3.8 for a 6-day second-stage anaerobic fermentation; th...

Embodiment 2

[0046] A kind of bamboo leaf enzyme, by weight:

[0047] Bamboo leaf pulp 31 perilla leaf pulp 5.9 carrot pulp + sweet potato pulp + yam pulp 8.3 Jerusalem artichoke powder 1.7 soybean meal powder 2.5 lactose 0.9 pectin esterase 5 lactic acid bacteria + brewer's yeast 4;

[0048] The preparation method of this bamboo leaf ferment comprises the following steps:

[0049] 1) cleaning, drying, crushing and beating bamboo leaves to obtain bamboo leaf pulp;

[0050] 2) adding lactose, Jerusalem artichoke powder, soybean meal powder, perilla leaf pulp, carrot pulp+sweet potato pulp+yam pulp to the bamboo leaf pulp, stirring evenly to obtain a mixed pulp;

[0051] 3) adjust the pH of the mixed slurry to 4.2;

[0052] 4) Put the mixed pulp into the fermentation container, treat it with an ultrasonic wave with a power of 435W for 38 minutes, seal it immediately, and carry out the first stage of anaerobic fermentation at 42°C for 7 days; lower the temperature to 37°C, and adjust the pH...

Embodiment 3

[0056] A kind of bamboo leaf enzyme, by weight:

[0057] Bamboo leaf pulp 37 Perilla leaf pulp 7.2 Sweet potato and yam pulp 10.1 Jerusalem artichoke powder 1.9 Soybean meal powder 2.8 Maltose 1.3 Protease 6 Bifid bacteria 8;

[0058] The preparation method of this bamboo leaf ferment comprises the following steps:

[0059] 1) cleaning, drying, crushing and beating bamboo leaves to obtain bamboo leaf pulp;

[0060] 2) adding maltose, Jerusalem artichoke powder, soybean meal powder, perilla leaf pulp, sweet potato and yam pulp to the bamboo leaf pulp, stirring evenly to obtain a mixed pulp;

[0061] 3) adjust the pH of the mixed slurry to 4.4;

[0062] 4) Put the mixed pulp into the fermentation container, treat it with an ultrasonic wave with a power of 465W for 44 minutes, seal it immediately, and conduct the first stage of anaerobic fermentation at 44°C for 8 days; lower the temperature to 36°C, and adjust the pH with lemon juice to 4.1 for a 7-day second-stage anaerobic fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com