Antibacterial oral care product for refreshing breath

A technology for oral care and oral cavity, applied in the direction of oral care, local antibacterial agents, skin care preparations, etc., to achieve the effect of inhibiting adhesion and growth, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

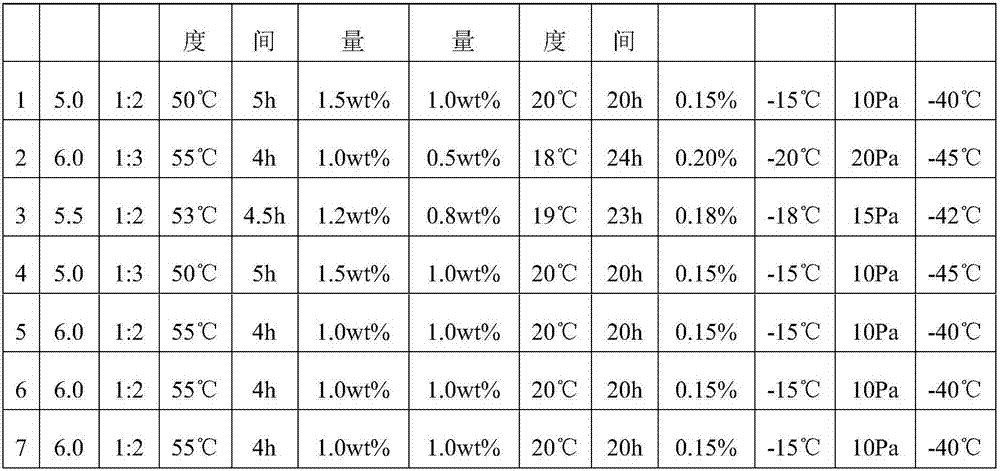

[0053] The quality index of the fruit and vegetable plant fermentation product that utilizes preparation method provided by the invention to make is as follows:

[0054] In the fruit and vegetable plant fermentation product, the content of protease exceeds 2000U / g, and the content of superoxide dismutase exceeds 5000U / g. Moreover, it also has the advantages of uniform color, unique fruit and vegetable aroma, accompanied by fermentation aroma, loose and no agglomeration.

[0055] The oral care article provided by the invention can be made into various preparations, so as to realize oral care through various ways of use. Therefore, in addition to the two active ingredients of Magnolia officinalis bark extract and fruit and vegetable plant fermentation products, the oral care product provided by the present invention can also contain oral acceptable auxiliary materials. Magnolia officinalis bark extract and fruit and vegetable plant fermentation products can be formulated into a...

Embodiment 1

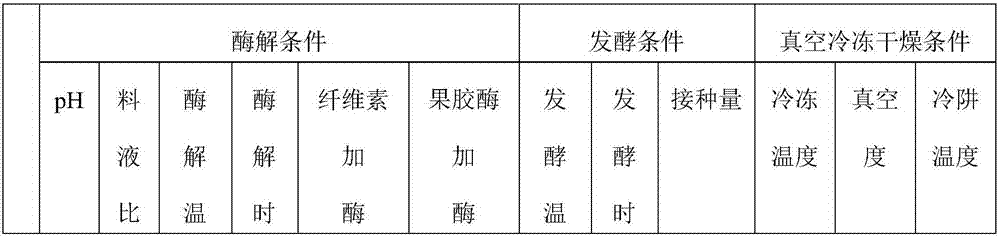

[0071] First prepare fruit and vegetable plant fermentation product, preparation method comprises the following steps (preparation conditions see Table 1):

[0072] (1) Apples are crushed into slag, and cellulase and pectinase are added for enzymolysis to obtain an enzymolysis mixture; the conditions for the enzymolysis are: pH is 5.0, the solid-liquid ratio of fruit and vegetable slag is 1:2, and the temperature The temperature is 50° C., the enzymatic hydrolysis time is 5 hours, and the amount of enzyme added to cellulose is 1.5 wt %, and the amount of enzyme added to pectinase is 1.0 wt %.

[0073] (2) Adjust the pH of the enzymolysis mixture to 3.5-4.0, and insert lactobacillus for fermentation to obtain a fermentation product; the fermentation conditions are as follows: the fermentation temperature is 20° C., the fermentation time is 20 h, and the inoculum size is 0.15%. The number of Lactobacillus casei in the fermented product obtained under such conditions is 5x10 8 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com