A processing technology and processing device for the tooth-shaped surface of the inner hole of a waveguide with a large length-to-diameter ratio

A technology with a large length-to-diameter ratio and a processing device, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low tool durability, large deformation of the process system, and large surface roughness value, etc., to achieve improved Tool durability, improved cooling effect, and reduced surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A processing technology and processing device for the toothed surface of the inner hole of a waveguide tube with a length of 1 meter and a large aspect ratio of the present invention will be described in detail below with reference to the drawings and embodiments.

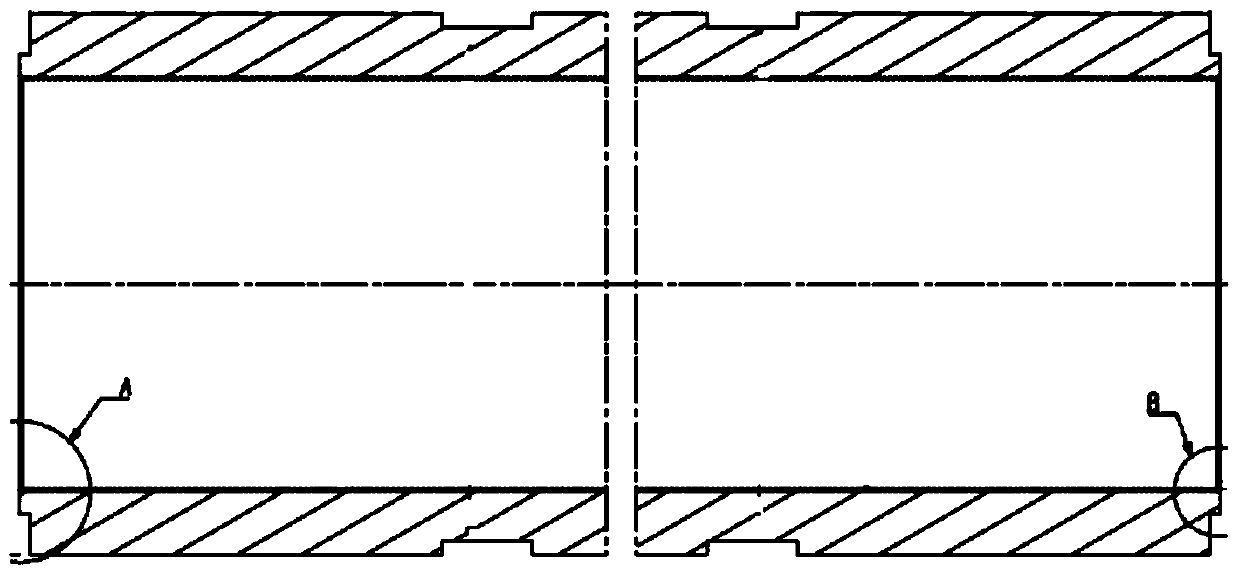

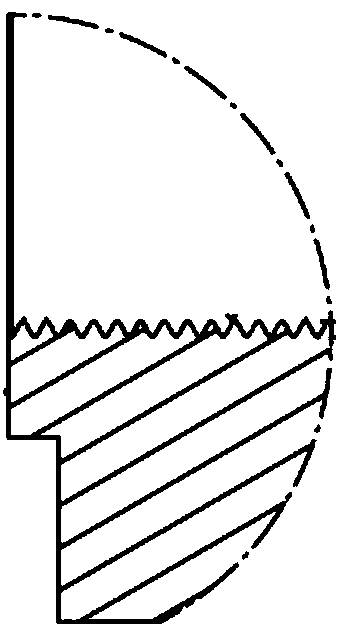

[0033] Such as figure 1 As shown, the 1-meter-long waveguide with large aspect ratio required for processing in the present invention is mainly used for transmitting MW level long-pulse millimeter waves. The value of the ripple period is P=0.8mm±0.02. The inner wall of the waveguide is a relatively smooth curved surface, which can effectively avoid tip discharge during high-power microwave transmission, and then efficiently transmit high-power long-pulse millimeter waves.

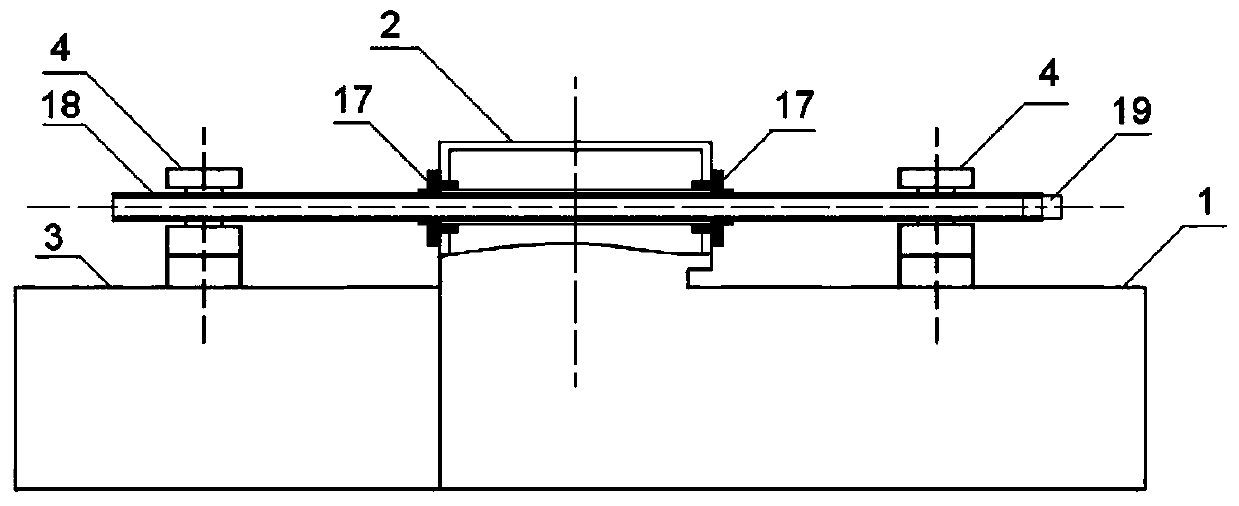

[0034] Such as figure 2 , 3 , 4, 5, and 6, a processing device of the present invention for processing the tooth profile surface of the inner hole of a waveguide with a large length-to-diameter ratio of 1 meter includes: 1 standard ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com