Temperature frequency characteristic regulator of microwave medium ceramic and LTCC material thereof

A technology of microwave dielectric ceramics and temperature-frequency characteristics, applied in the direction of silicate, alkaline earth metal silicate, printed circuit, etc., can solve the problems of low dielectric constant, device insulation resistance and reliability reduction, and achieve low dielectric constant, stable phase structure, and the effects of excellent microwave dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

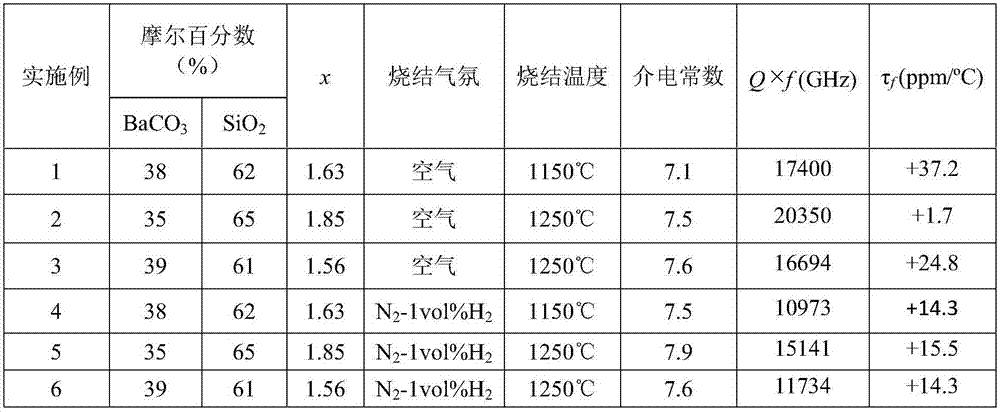

[0052] A microwave dielectric ceramic, its preparation method is carried out according to the following steps:

[0053] (1) Analytical pure BaCO 3 , SiO 2 After mixing according to the mole percentage ratio in Table 1, using zirconium balls as the medium and deionized water as the dispersant, the powder was mixed and stirred for 3 hours with a ball mill at a speed of 360 r / min; the obtained slurry was dried at 1100 Pre-fired at ℃ for 3 hours to obtain pre-fired ceramic powder;

[0054] (2) The pre-fired ceramic powder obtained in step (1) is subjected to wet ball milling again, and after drying, 3wt% polyvinyl alcohol (PVA) binder is added to the dry powder to granulate, and the powder is granulated under a pressure of 100MPa Press it into a cylindrical green sample with a thickness-to-diameter ratio of 0.4-0.6; after tableting, sinter in air or a reducing atmosphere at 1150-1250°C to obtain microwave dielectric ceramics or ceramics as described in Table 1. Temperature-freq...

Embodiment 7~11

[0060] A kind of LTCC microwave dielectric ceramic material, its preparation method is carried out according to the following steps:

[0061] (1) According to the chemical expression BaAl 2 Si 2 o 8 The stoichiometric ratio of BaCO 3 、Al 2 o 3 and SiO 2 , after mixing, use zirconium balls as the medium and deionized water as the dispersant, mix and stir the powder for 3 hours with a ball mill at a speed of 360r / min; dry the obtained slurry and pre-calcine at 1200°C for 3 hours to obtain pre-calcined ceramic powder;

[0062] (2) The calcined ceramic powder obtained in step (1), the microwave dielectric ceramic temperature-frequency characteristic regulator BaSi described in Examples 1 to 6, x o 2x+1 And sintering aid, the preferred sintering aid is LiF, after mixing according to the mass ratio y:(99-y):1, carry out wet ball milling treatment, after drying, add 3wt% polyvinyl alcohol (PVA) binder to dry The powder is granulated, and pressed under a pressure of 100 MPa i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com