A kind of microwave dielectric ceramic temperature-frequency characteristic regulator and its ltcc material

一种微波介质陶瓷、温频特性的技术,应用在硅酸盐、碱土金属硅酸盐、印刷电路等方向,能够解决器件绝缘电阻和可靠性降低、低介电常数等问题,达到低介电常数、稳定相结构、优异微波介电性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

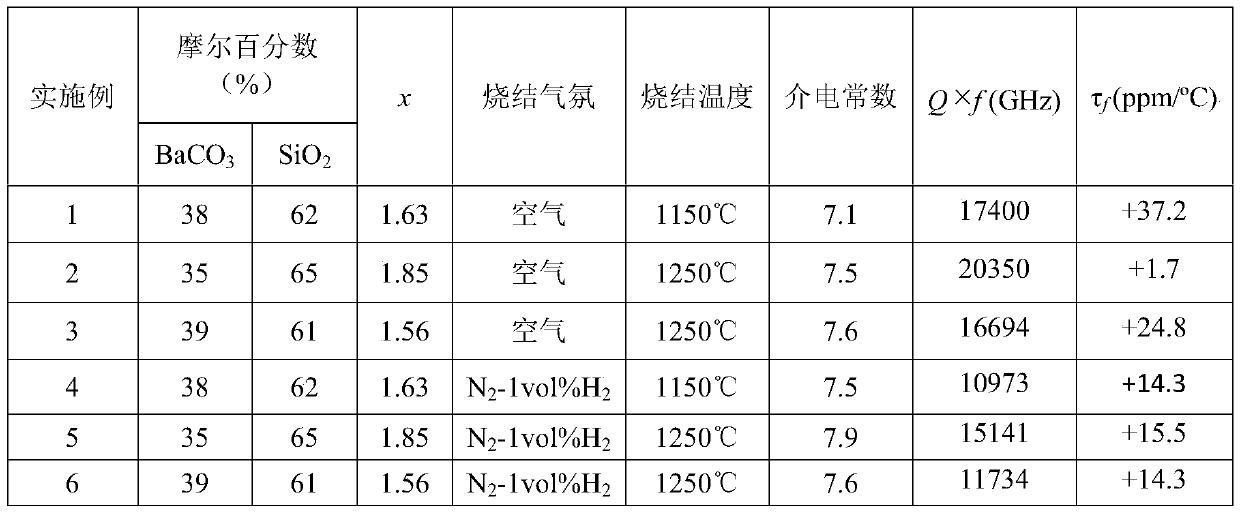

[0052] A microwave dielectric ceramic, its preparation method is carried out according to the following steps:

[0053] (1) Analytical pure BaCO 3 , SiO 2 After mixing according to the mole percentage ratio in Table 1, using zirconium balls as the medium and deionized water as the dispersant, the powder was mixed and stirred for 3 hours with a ball mill at a speed of 360 r / min; the obtained slurry was dried at 1100 Pre-fired at ℃ for 3 hours to obtain pre-fired ceramic powder;

[0054] (2) The pre-fired ceramic powder obtained in step (1) is subjected to wet ball milling again, and after drying, 3wt% polyvinyl alcohol (PVA) binder is added to the dry powder to granulate, and the powder is granulated under a pressure of 100MPa Press it into a cylindrical green sample with a thickness-to-diameter ratio of 0.4-0.6; after tableting, sinter in air or a reducing atmosphere at 1150-1250°C to obtain microwave dielectric ceramics or ceramics as described in Table 1. Temperature-freq...

Embodiment 7~11

[0060] A kind of LTCC microwave dielectric ceramic material, its preparation method is carried out according to the following steps:

[0061] (1) According to the chemical expression BaAl 2 Si 2 o 8 The stoichiometric ratio of BaCO 3 、Al 2 o 3 and SiO 2 , after mixing, use zirconium balls as the medium and deionized water as the dispersant, mix and stir the powder for 3 hours with a ball mill at a speed of 360r / min; dry the obtained slurry and pre-calcine at 1200°C for 3 hours to obtain pre-calcined ceramic powder;

[0062] (2) The calcined ceramic powder obtained in step (1), the microwave dielectric ceramic temperature-frequency characteristic regulator BaSi described in Examples 1 to 6, x o 2x+1 And sintering aid, the preferred sintering aid is LiF, after mixing according to the mass ratio y:(99-y):1, carry out wet ball milling treatment, after drying, add 3wt% polyvinyl alcohol (PVA) binder to dry The powder is granulated, and pressed under a pressure of 100 MPa i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com