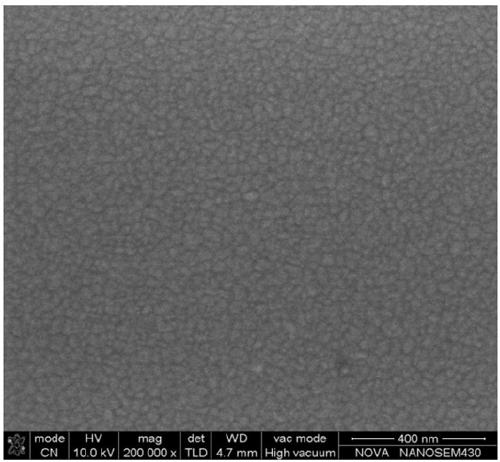

A kind of nano-α-alumina/chromia composite coating and preparation method thereof

A composite coating and aluminum oxide technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of poor film/substrate bonding force, large internal stress of coating, difficult engineering application, etc. Achieve low cutting heat, low friction coefficient, and suppress target poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Select AlCr40 alloy as the high-power pulse magnetron sputtering target, and install it in the corresponding target station of high-power pulse magnetron sputtering;

[0033] (2) Choose W6Mo5Cr4V2 high-speed steel as the substrate, cut it into Φ10×5mm size, after conventional quenching + 560°C (3 times) tempering, grind and polish the coating surface, and put it in anhydrous alcohol solution for ultrasonic cleaning for 15min Remove the oil, put it on the sample stage after drying, and adjust the distance between the sample and the target to 100mm;

[0034] (3) After pre-pumping the background vacuum to 10-20Pa, turn on the vacuum heating and baking system, set the baking temperature at 150°C, and then pump to the background vacuum of 6×10 -4 Pa, fill the vacuum chamber with Ar gas and adjust the throttle valve until the vacuum degree returns to 20Pa, open the throttle valve after stabilizing for 10 minutes, and then pump to 6×10 -4 Pa background vacuum;

[0035] (...

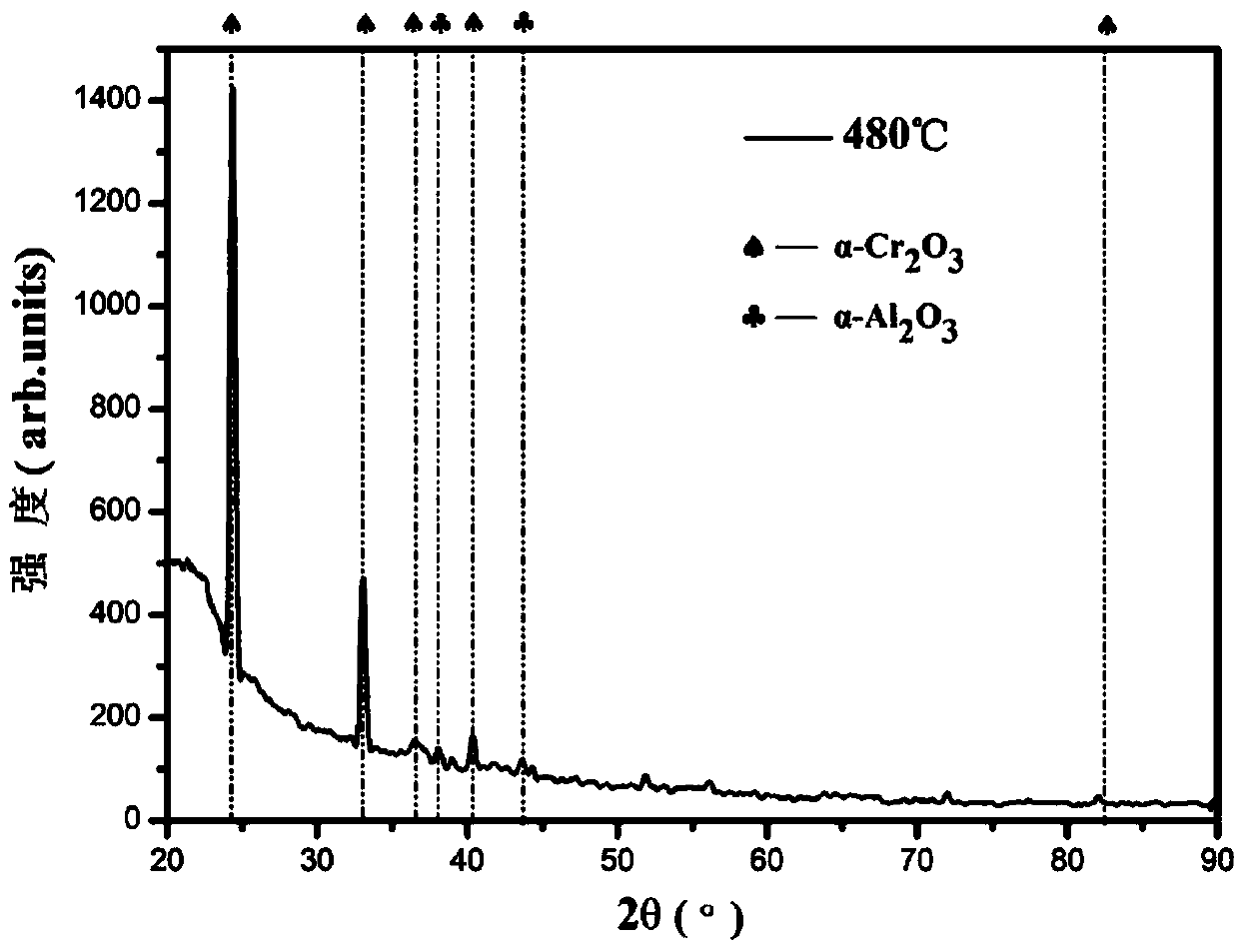

Embodiment 2

[0041] (1) Select AlCr40 alloy as the high-power pulse magnetron sputtering target, and install it in the corresponding target station of high-power pulse magnetron sputtering;

[0042] (2) Choose W6Mo5Cr4V2 high-speed steel as the substrate, cut it into Φ10×5mm size, after conventional quenching + 560°C (3 times) tempering, grind and polish the coating surface, and put it in anhydrous alcohol solution for ultrasonic cleaning for 15min Remove the oil, put it on the sample stage after drying, and adjust the distance between the sample and the target to 100mm;

[0043] (3) After pre-pumping the background vacuum to 10-20Pa, turn on the vacuum heating and baking system, set the baking temperature at 150°C, and then pump to the background vacuum of 6×10 -4 Pa, fill the vacuum chamber with Ar gas and adjust the throttle valve until the vacuum degree returns to 20Pa, open the throttle valve after stabilizing for 10 minutes, and then pump to 6×10 -4 Pa background vacuum;

[0044] (...

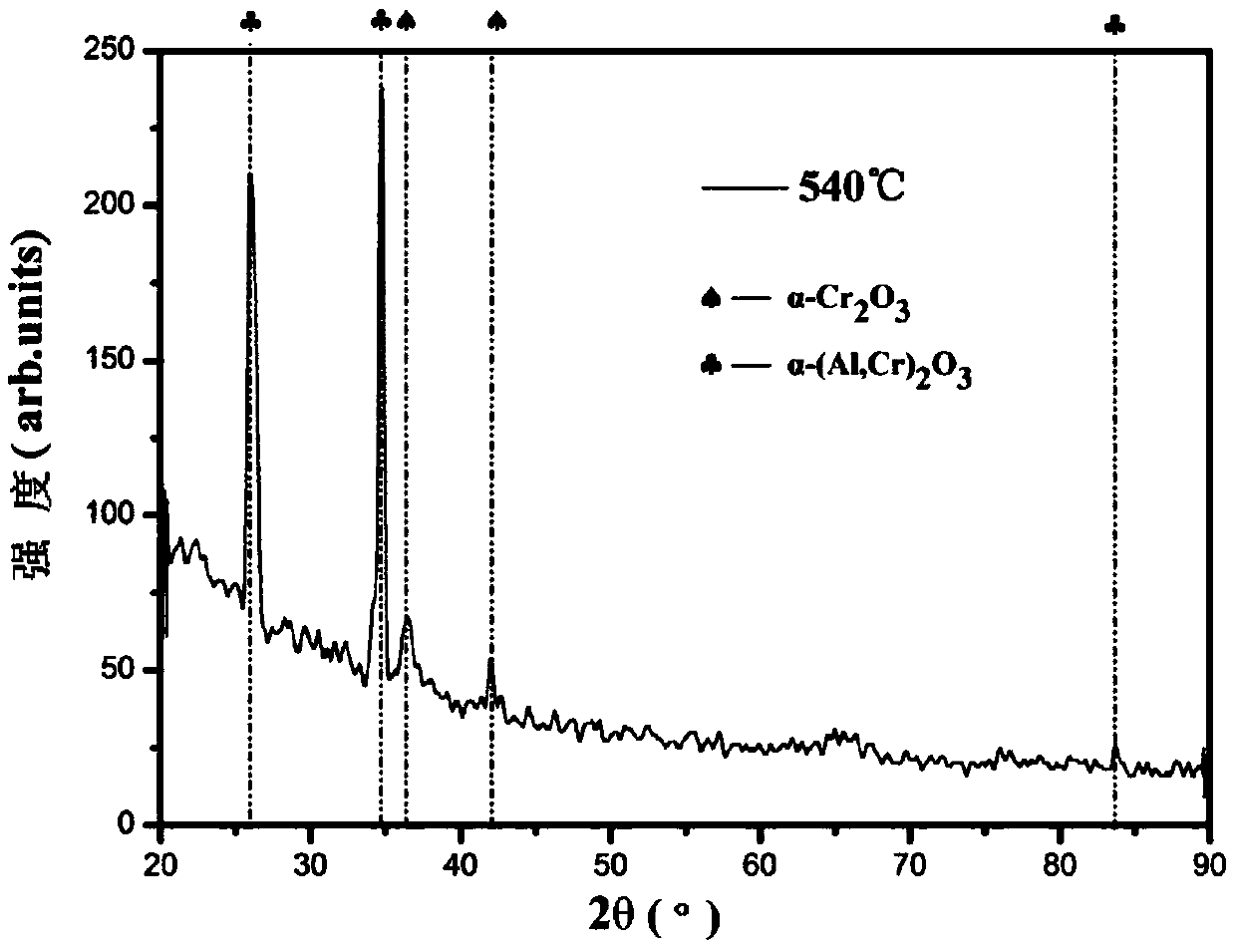

Embodiment 3

[0050] (1) Select AlCr5 alloy as the high-power pulse magnetron sputtering target, and install it in the corresponding target station of high-power pulse magnetron sputtering;

[0051] (2) Choose W6Mo5Cr4V2 high-speed steel as the substrate, cut it into Φ10×5mm size, after conventional quenching + 560°C (3 times) tempering, grind and polish the coating surface, and put it in anhydrous alcohol solution for ultrasonic cleaning for 15min Remove the oil, put it on the sample stage after drying, and adjust the distance between the sample and the target to 100mm;

[0052] (3) After pre-pumping the background vacuum to 10-20Pa, turn on the vacuum heating and baking system, set the baking temperature at 150°C, and then pump to the background vacuum of 6×10 -4 Pa, fill the vacuum chamber with Ar gas and adjust the throttle valve until the vacuum degree returns to 20Pa, open the throttle valve after stabilizing for 10 minutes, and then pump to 6×10 -4 Pa background vacuum;

[0053] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com