Preparation process of high temperature oxidation resistant zrnx/(zralfe)n/(zralfem)n composite gradient coating

A technology of anti-oxidation at high temperature and gradient coating, applied in metal material coating process, coating, superimposed layer plating, etc. Maintains stability and mitigates the effect of reduced binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

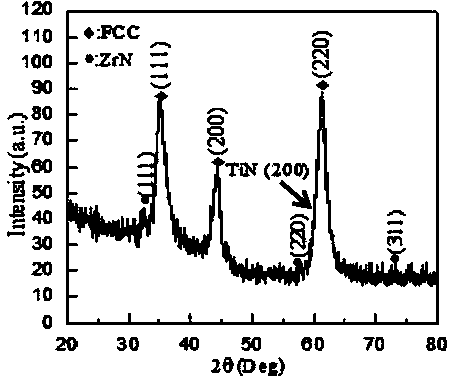

Image

Examples

Embodiment 1

[0030] a. Clean the base material:

[0031] Zirconium alloy (Zr 4 Alloy) substrate for grinding and polishing; then use acetone and ethanol as solvents to degrease and degrease and clean in an ultrasonic instrument; then clean with deionized water, dry and put into a vacuum chamber, the vacuum degree is -4 Pa;

[0032] b. Treatment of the substrate before deposition:

[0033] Keep the vacuum chamber vacuum -4 Under the condition of Pa, the reverse sputtering was used for 15 min to clean the zirconium alloy substrate; the reverse sputtering bias voltage was -450 V; the reverse sputtering gas was Ar; the reverse sputtering pressure in the vacuum chamber was 3.5 Pa;

[0034] c. Pre-sputtering:

[0035] Keep the vacuum chamber vacuum -4 Under the condition of Pa, pre-sputtering was used to clean each target for 15 min to remove impurities on the target surface; the pre-sputtering power was 120 W; the pre-sputtering bias was -120 V; the pre-sputtering gas was Ar; The pre-spu...

Embodiment 2

[0040] a. Clean the base material:

[0041] Zirconium alloy (Zr 4 Alloy) substrate for grinding and polishing; then use acetone and ethanol as solvents to degrease and degrease and clean in an ultrasonic instrument; then clean with deionized water, dry and put into a vacuum chamber, the vacuum degree is -4 Pa;

[0042] b. Treatment of the substrate before deposition:

[0043] Keep the vacuum chamber vacuum -4 Under the condition of Pa, the reverse sputtering was used for 15 min to clean the zirconium alloy substrate; the reverse sputtering bias voltage was -450 V; the reverse sputtering gas was Ar; the reverse sputtering pressure in the vacuum chamber was 3.5 Pa;

[0044] c. Pre-sputtering:

[0045] Keep the vacuum chamber vacuum -4 Under the condition of Pa, pre-sputtering was used to clean each target for 15 min to remove impurities on the target surface; the pre-sputtering power was 120 W; the pre-sputtering bias was -120 V; the pre-sputtering gas was Ar; The pre-spu...

Embodiment 3

[0050] a. Clean the base material:

[0051] Zirconium alloy (Zr 4 Alloy) substrate for grinding and polishing; then use acetone and ethanol as solvents to degrease and degrease and clean in an ultrasonic instrument; then clean with deionized water, dry and put into a vacuum chamber, the vacuum degree is -4 Pa;

[0052] b. Treatment of the substrate before deposition:

[0053] Keep the vacuum chamber vacuum -4Under the condition of Pa, the reverse sputtering was used for 15 min to clean the zirconium alloy substrate; the reverse sputtering bias voltage was -450 V; the reverse sputtering gas was Ar; the reverse sputtering pressure in the vacuum chamber was 3.5 Pa;

[0054] c. Pre-sputtering:

[0055] Keep the vacuum chamber vacuum -4 Under the condition of Pa, pre-sputtering was used to clean each target for 15 min to remove impurities on the target surface; the pre-sputtering power was 120 W; the pre-sputtering bias was -120 V; the pre-sputtering gas was Ar; The pre-sputt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com