Dual-core cage-shaped earth samarium (III) organic complex, and preparation method and application thereof

An organic complex and cage-like technology, which is applied in the field of synthesis of new catalytic materials, achieves the effects of mild reaction conditions, mild catalytic reaction conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

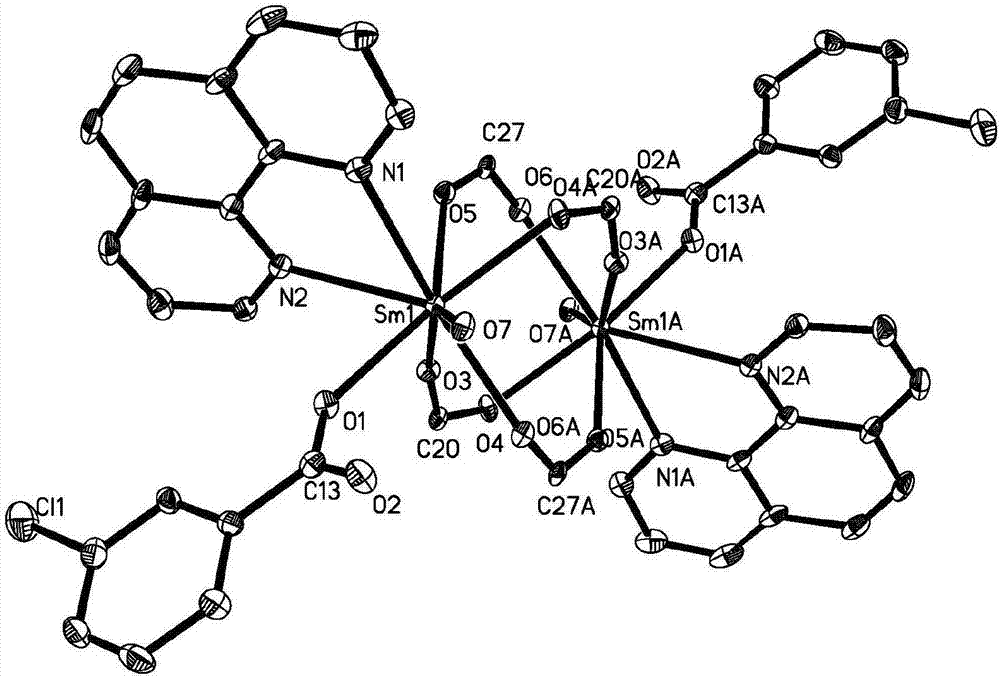

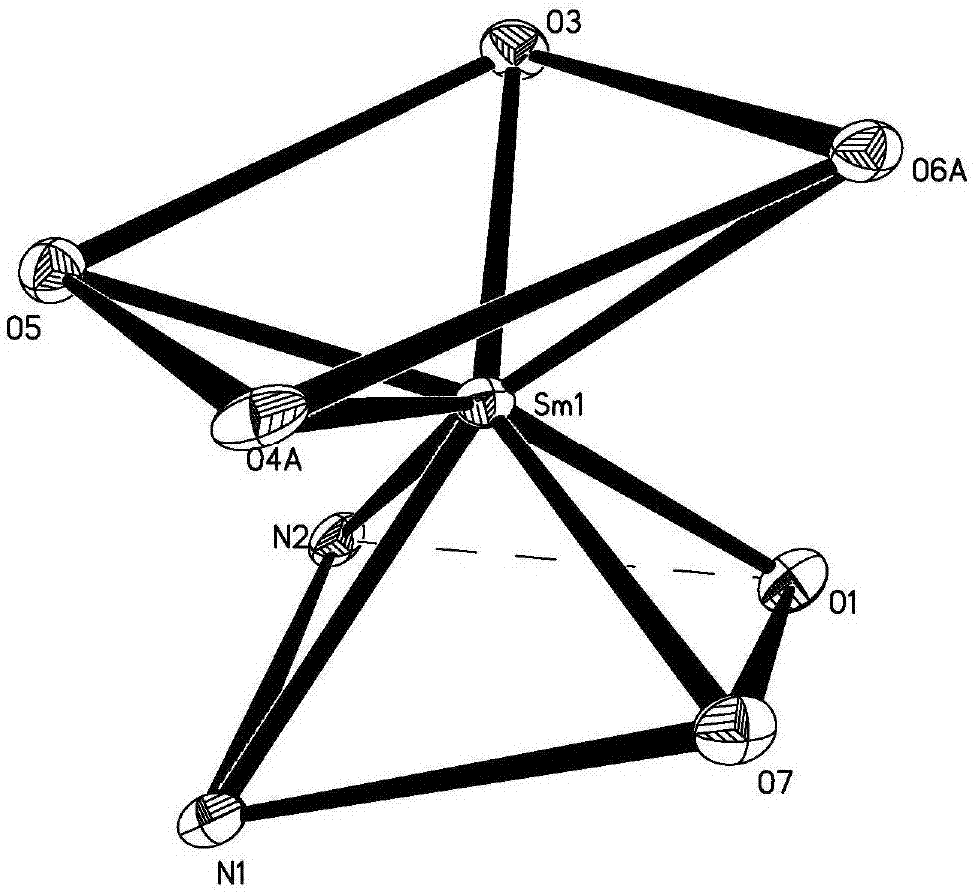

[0038] A Novel Dinuclear Caged Rare Earth Samarium(III) Organic Complex Sm 2 (C 7 h5 ClCOO) 6 (C 12 h 8 N 2 ) 2 (H 2 O) 2 The synthesis, its reaction steps are as follows:

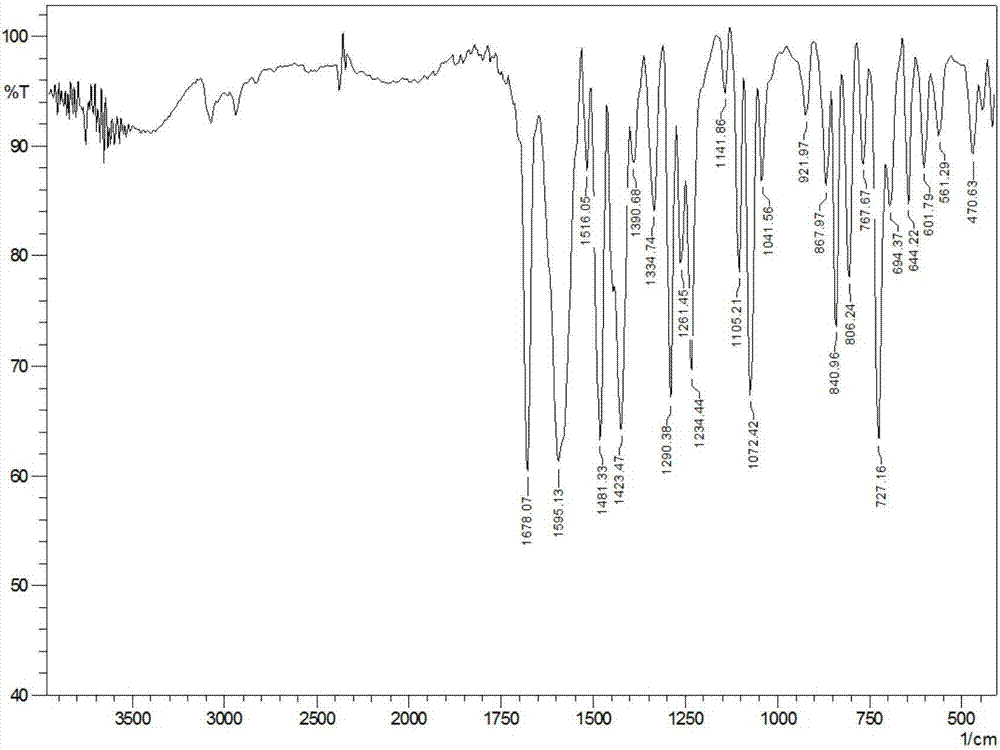

[0039] Add 0.64mmol (100.20mg) o-chlorobenzoic acid, 0.32mmol (82.15mg) samarium chloride and 0.32mmol (63.40mg) 1,10-phenanthroline into a mixed solvent of 20mL acetonitrile and water (volume ratio 5: 1), react for 1 hour, adjust the pH value to 6.5 with a concentration of 0.3mol / L sodium hydroxide solution, and react for 14 hours at 80°C. After the reaction is completed, a red solution is obtained, filtered, and the filtrate is covered with a fresh-keeping film, and placed Naturally volatilized at room temperature, a colorless crystal suitable for X-ray single crystal structure analysis was precipitated after one month, and the yield was 45.36%. M.P.205~207℃; IR main absorption peaks are: 1678(vs), 1595(vs), 1484(vs), 1423(vs),, 1290(m), 1234(w), 1105(w), 1072( m), 841(m), 806(w), 727(vs), 694(...

Embodiment 2

[0041] A Novel Dinuclear Caged Rare Earth Samarium(III) Organic Complex Sm 2 (C 7 h 5 ClCOO) 6 (C 12 h 8 N 2 ) 2 (H 2 O) 2 The synthesis of:

[0042] Add 0.87mmol (136.21mg) o-chlorobenzoic acid, 0.36mmol (143.77mg) samarium acetate tetrahydrate and 0.24mmol (47.55mg) 1,10-phenanthroline to 25mL N,N'-dimethylacetamide, ethanol In a mixed solvent with water (volume ratio 5:3:2), react. After 2 hours, use 0.5mL of concentrated ammonia water to adjust the pH value to 6.8, and react at 70°C for 13 hours. After the reaction is completed, a red solution is obtained and filtered. , the filtrate is covered with a layer of fresh-keeping film, placed at room temperature to volatilize naturally, and after two weeks, colorless crystals suitable for X-ray single crystal structure analysis are precipitated, with a yield of 43.21%.

Embodiment 3

[0044] A Novel Dinuclear Caged Rare Earth Samarium(III) Organic Complex Sm 2 (C 7 h 5 ClCOO) 6 (C 12 h 8 N 2 ) 2 (H 2 O) 2 The synthesis of:

[0045] Add 0.56mmol (87.68mg) of o-chlorobenzoic acid, 0.28mmol (139.65mg) of samarium carbonate hydrate and 0.36mmol (71.32mg) of 1,10-phenanthroline into a mixed solvent of 20mL of acetonitrile, ethanol and water (volume ratio 2:3:1), after 2 hours, adjust the pH value to 6.0 with triethylamine, and react at 75°C for 15 hours. It evaporates naturally at room temperature, and after three weeks, a colorless crystal suitable for X-ray single crystal structure analysis is precipitated, with a yield of 48.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com