Method of preparing phosphate

A technology of phosphate ester and pyrophosphoric acid, which is applied in the field of medicine and chemical industry, can solve the problems of poor feasibility of industrial production, poor stability of UTP, poor reaction yield, etc., and achieve the effect of easy industrial production, less operation steps and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a preparation method of phosphate ester, which comprises the following steps:

[0029] The pyrophosphate active compound represented by formula II reacts with the uridine monophosphate or its salt represented by formula III in a hydrophilic solvent under the action of a double metal ion composite catalyst to obtain P represented by formula I 1 ,P 4 -Bis(5'-uridine) tetraphosphate;

[0030]

[0031] In formula II, X is imidazolyl, N-methylimidazolyl or 1,2,4-triazolyl;

[0032] The double metal ion in the double metal ion composite catalyst is Zn 2+ , Mn 2+ , Mg 2+ , Fe 2+ , Fe 3+ And Al 3+ A combination of any two of them.

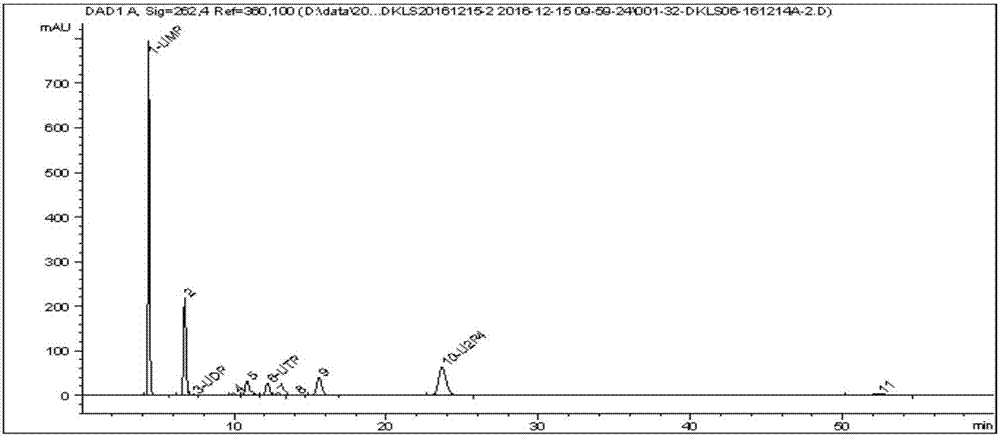

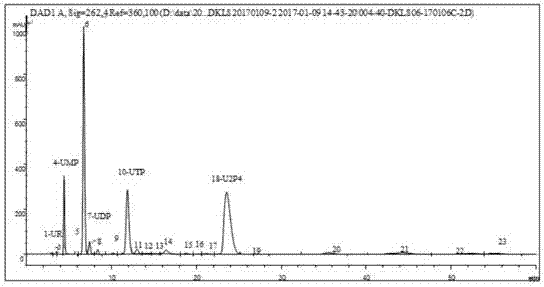

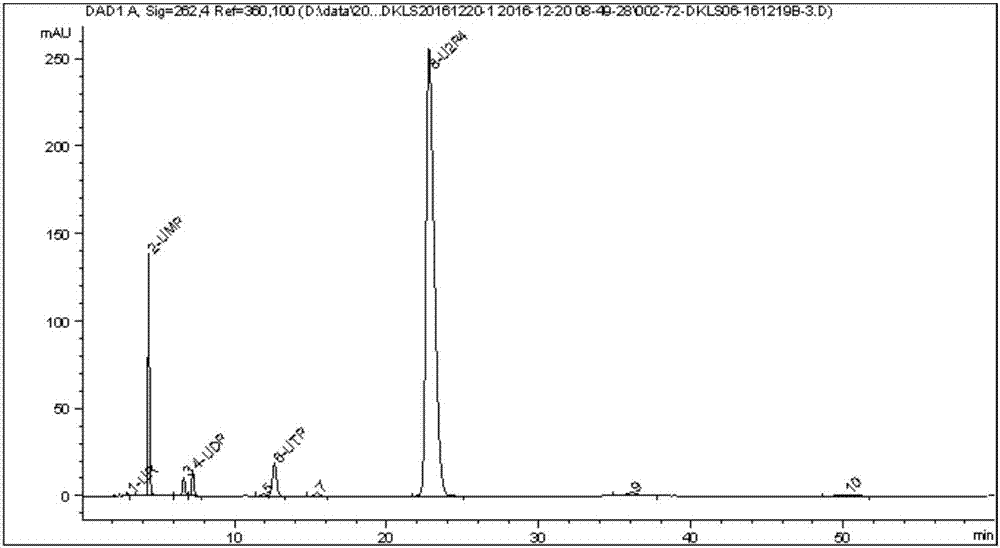

[0033] The preparation method provided by the invention has the advantages of easy availability of raw materials, low raw material cost, few operation steps, simple process, high reaction yield (product separation yield of more than 80%), high product purity (HPLC purity more than 99.9%), and easy The advantages of industrial ...

Embodiment 1

[0060] Example 1 Preparation of n-butylamine pyrophosphate (PPi-TBA)

[0061]

[0062] Tetrasodium pyrophosphate (26.6g, 0.1mol) was dissolved in deionized water (500mL), the aqueous solution was passed through a strong ion exchange column (pk216 proton type), the fractions containing pyrophosphate were combined, and tributylamine (37.1g , 0.2mol) to form a salt, the eluate is concentrated into an oily substance by a rotary evaporator. The oil was charged with water through 1,4-dioxane (100 mL), and the water was repeated 3 times to obtain the oily n-butylamine pyrophosphate (quantitative).

Embodiment 2

[0063] Example 2 Preparation of imidazole pyrophosphate (II)

[0064]

[0065] In a DMF (150 mL) solution of n-butylamine pyrophosphate (54.8 g, 0.1 mol), 1,1-carbonyldiimidazole (37.7 g, 0.3 mol) was added as an activator under nitrogen protection, and the mixture was stirred at room temperature for 2 hours. Methanol (3.2g, 0.1mol) was added to the reaction solution, stirred at room temperature for 10 minutes, and then pumped under a vacuum of 5 mmHg column, and stirred for 10 minutes. A DMF solution of imidazole pyrophosphate (II) is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com