An oil-based cleaning agent for cleaning petrochemical equipment

A cleaning agent and equipment technology, which is applied in the field of petrochemical industry, can solve the problems of long cleaning time, incomplete cleaning, and large energy consumption, and achieve the effect of shortening the maintenance period, omitting steam purging, and reducing the burden on operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

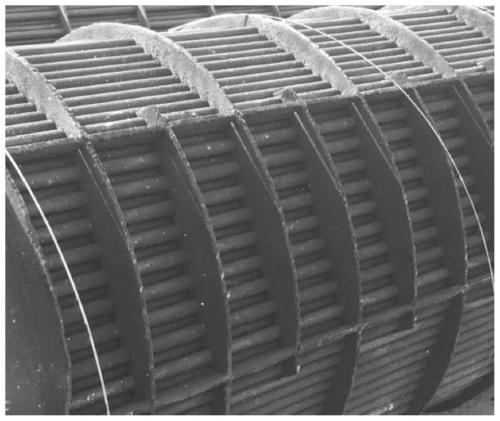

Image

Examples

Embodiment 1

[0039] Embodiment 1. is used for the oil-based cleaning agent of petrochemical equipment cleaning, and each component is by mass percentage,

[0040] Isogenic tridecyl polyoxyethylene ether 10%

[0041] Dihexyl succinate sulfonate 1%

[0042] Octylphenol ethoxylate 1.5%

[0043] Tetrasodium EDTA 1.5%

[0044] Triethanolamine Oleic Soap 1%

[0045] FCC Diesel Top Up 100%

[0046] The preparation method of the oil-based cleaning agent is as follows: in a blender, add the raw materials of each component weighed in a certain proportion, mix them evenly under high-speed stirring, heat properly if necessary, and fill 200L after testing for sufficient mutual solubility Finished barrels, sealed for future use.

Embodiment 2

[0047] Embodiment 2. a kind of oil base cleaning agent that is used for petrochemical equipment cleaning, each component is by mass percentage,

[0048] Isogenic tridecyl polyoxyethylene ether 11%

[0049] Dihexyl succinate sulfonate 1.5%

[0050]Octylphenol ethoxylate 1.6%

[0051] Tetrasodium EDTA 1.4%

[0052] Triethanolamine Oleic Soap 1.2%

[0053] Citric Acid 1.2%

[0054] FCC Diesel Top Up 100%

[0055] The preparation method is the same as in Example 1.

Embodiment 3

[0056] Embodiment 3. a kind of oil-based cleaning agent that is used for petrochemical equipment cleaning, each component is by mass percentage,

[0057] Isodecanol ethoxylates 12%

[0058] Di-isooctyl sulfonate 1.5%

[0059] Nonylphenol ethoxylates 2%

[0060] Disodium EDTA 1.2%

[0061] Rosin Maleamide Ethanol 1.5%

[0062] Naphtha Top Up 100%

[0063] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com