Heat treatment method of large-thickness high-toughness 15CrMoR steel plate

A heat treatment method and high toughness technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of difficult matching of steel plate strength and toughness, harsh service conditions of steel plates, and unsatisfactory steel plates, so as to improve economic and social benefits, Good matching of strength and toughness, the effect of solving technical problems of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

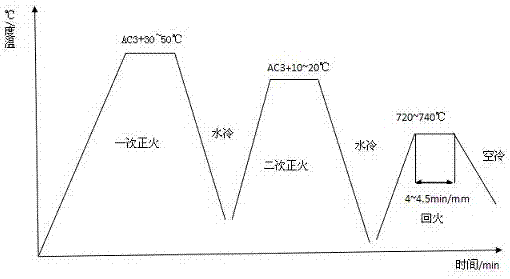

[0018] Embodiment 1: The heat treatment method of the large-thickness and high-toughness 15CrMoR steel plate adopts the following process.

[0019] Steel type 15CrMoR, chemical composition (wt): C 0.12%, Si 0.23%, Mn 0.50%, P 0.007%, S 0.002%, Ni 0.15%, Cr 0.98%, Mo 0.55%, TAl (full aluminum) 0.035%, The balance is Fe and unavoidable impurities. The thickness of the steel plate is 110mm, the AC1 is 760°C, and the AC3 is 877°C. The specific heat treatment process is as follows:

[0020] The first normalizing temperature is 925°C, the total heating time is PLC+20min, and the maximum water volume is 4350m 3 / h, the water temperature is kept at 23°C, the temperature of returning to red is 210°C; the second normalizing temperature is 890°C, the total heating time is PLC+15min, and the maximum water volume of water cooling is ≥4680m 3 / h, the water temperature is kept at 21°C, the swinging time is 20min, and the cooling is guaranteed to be at room temperature (the surface temperat...

Embodiment 2

[0022] Embodiment 2: The heat treatment method of the large-thickness and high-toughness 15CrMoR steel plate adopts the following process.

[0023] Steel type 15CrMoR, chemical composition (wt): C 0.12%, Si 0.24%, Mn 0.49%, P 0.006%, S 0.001%, Ni 0.15%, Cr 1.02%, Mo 0.53%, TAl (full aluminum) 0.034%, The balance is Fe and unavoidable impurities. The thickness of the steel plate is 120mm, the AC1 is 761°C, and the AC3 is 875°C. The specific heat treatment process is as follows:

[0024] The first normalizing temperature is 920°C, the total heating time is PLC+20min, and the maximum water volume is 4450m 3 / h, the water temperature is kept at 22°C, the temperature of returning to red is 200°C; the second normalizing temperature is 895°C, the total heating time is PLC+18min, and the maximum water volume of water cooling is ≥4650m 3 / h, the water temperature is kept at 23°C, the swing time is 20min, and the cooling is guaranteed to be room temperature (the surface temperature of...

Embodiment 3

[0026] Embodiment 3: The heat treatment method of the large-thickness and high-toughness 15CrMoR steel plate adopts the following process.

[0027] Steel type 15CrMoR, chemical composition (wt): C 0.13%, Si 0.25%, Mn 0.49%, P 0.006%, S 0.001%, Ni 0.14%, Cr 1.00%, Mo 0.54%, TAl (full aluminum) 0.037%, The balance is Fe and unavoidable impurities. The thickness of the steel plate is 125mm, the AC1 is 758°C, and the AC3 is 880°C. The specific heat treatment process is as follows:

[0028] The first normalizing temperature is 930°C, the total heating time is PLC+25min, and the maximum water volume is 4420m 3 / h, the water temperature is kept at 24°C, the temperature of returning to red is 190°C; the second normalizing temperature is 900°C, the total heating time is PLC+20min, and the maximum water volume of water cooling is ≥4700m 3 / h, the water temperature is kept at 20°C, the rocking time is 25min, and the cooling is guaranteed to be room temperature (the surface temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap