High-speed steel roller containing boron aluminum

A high-speed steel and aluminum-boron technology, which is applied in the field of aluminum-boron high-speed steel rolls and high-speed steel rolls, can solve the problems of large amount of precious alloys and high production costs of rolls, and achieve excellent oxidation resistance, roll cost reduction, and excellent anti-oxidation properties. The effect of high temperature tempering softening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

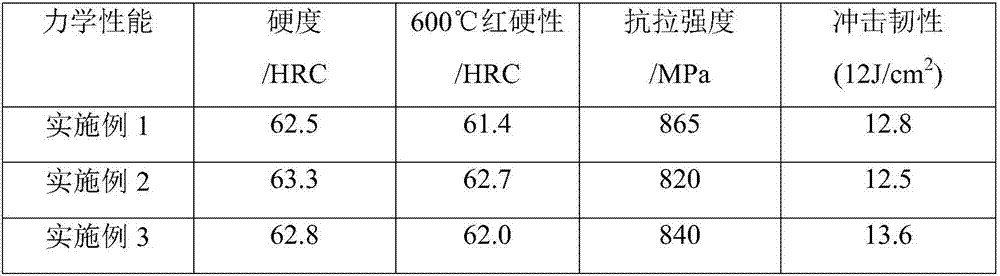

Examples

Embodiment 1

[0018] An aluminum-boron-containing high-speed steel roll is characterized in that it is smelted in an electric furnace, and the specific preparation process steps are:

[0019] 1) Melt aluminum-boron high-speed steel in a 500 kg medium-frequency induction furnace first. The chemical composition and mass fraction of the aluminum-boron high-speed steel molten steel are 1.67C, 1.36B, 1.05Al, 5.37Cr, 2.17Mo, 0.99Si, 0.67Mn, 1.36V, 0.019S, 0.028P, the balance Fe, when the temperature of the molten steel reaches 1623°C, the molten steel is taken out of the furnace into the ladle, and the bottom of the ladle is pre-added with an amorphous and nanocrystalline modifier with a thickness of 0.18mm. The chemical composition and mass fraction of the modifier is 21.60% B, 1.23% Rb, 21.69% Al, 3.66% Ti, 1.08% C, 5.21% Ca, the balance is Fe and inevitable impurity elements, amorphous and nanocrystalline modification The amount of additive added accounts for 0.63% of the mass fraction of the ...

Embodiment 2

[0022] An aluminum-boron-containing high-speed steel roll is characterized in that it is smelted in an electric furnace, and the specific preparation process steps are:

[0023] 1) Melt aluminum-boron high-speed steel in a 1000 kg medium-frequency induction furnace first. The chemical composition and mass fraction of aluminum-boron high-speed steel molten steel are 1.92C, 1.13B, 1.28Al, 5.04Cr, 2.55Mo, 0.78Si, 0.94Mn, 1.14V, 0.025S, 0.026P, the balance Fe, when the temperature of the molten steel reaches 1648°C, the molten steel is taken out of the furnace into the ladle, and the bottom of the ladle is pre-added with an amorphous and nanocrystalline modifier with a thickness of 0.69mm. The chemical composition and mass fraction of the modifier is 20.34% B, 1.44% Rb, 21.47% Al, 4.01% Ti, 0.91% C, 5.56% Ca, the balance is Fe and inevitable impurity elements, amorphous and nanocrystalline modification The amount of additive added accounts for 0.87% of the mass fraction of the mol...

Embodiment 3

[0026] An aluminum-boron-containing high-speed steel roll is characterized in that it is smelted in an electric furnace, and the specific preparation process steps are:

[0027] 1) Melt aluminum-boron high-speed steel in a 750 kg medium-frequency induction furnace first. The chemical composition and mass fraction of the aluminum-boron high-speed steel molten steel are 1.82C, 1.19B, 1.20Al, 5.25Cr, 2.46Mo, 0.90Si, 0.85Mn, 1.27V, 0.022S, 0.031P, the balance Fe, when the temperature of the molten steel reaches 1641°C, the molten steel is taken out of the furnace into the ladle, and the bottom of the ladle is pre-added with an amorphous and nanocrystalline modifier with a thickness of 0.54mm. The chemical composition and mass fraction of the modifier is 20.99% B, 1.28% Rb, 21.53% Al, 3.84% Ti, 0.97% C, 5.41% Ca, the balance is Fe and inevitable impurity elements, amorphous and nanocrystalline modification The amount of additive added accounts for 0.75% of the mass fraction of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com