A cooling tower device and control method with functions of replenishing water and anti-scaling

A cooling tower and functional technology, applied in water shower coolers, damage protection, heat exchange equipment, etc., can solve the problems of reduced heat exchange efficiency of cooling towers, easy to produce scale, loss of operating costs, etc., to reduce operating costs, reduce Fouling problem and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

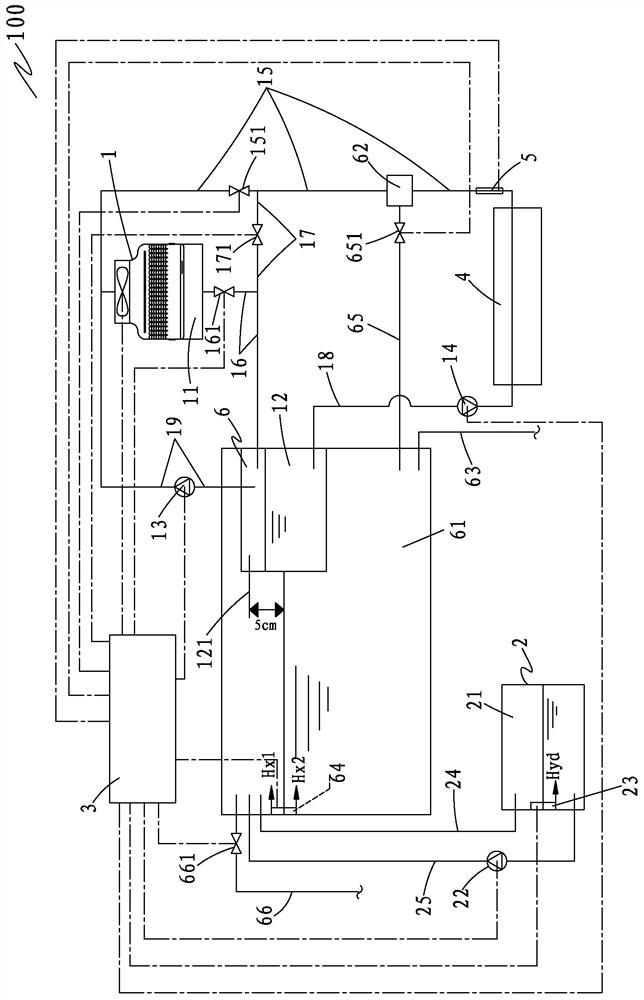

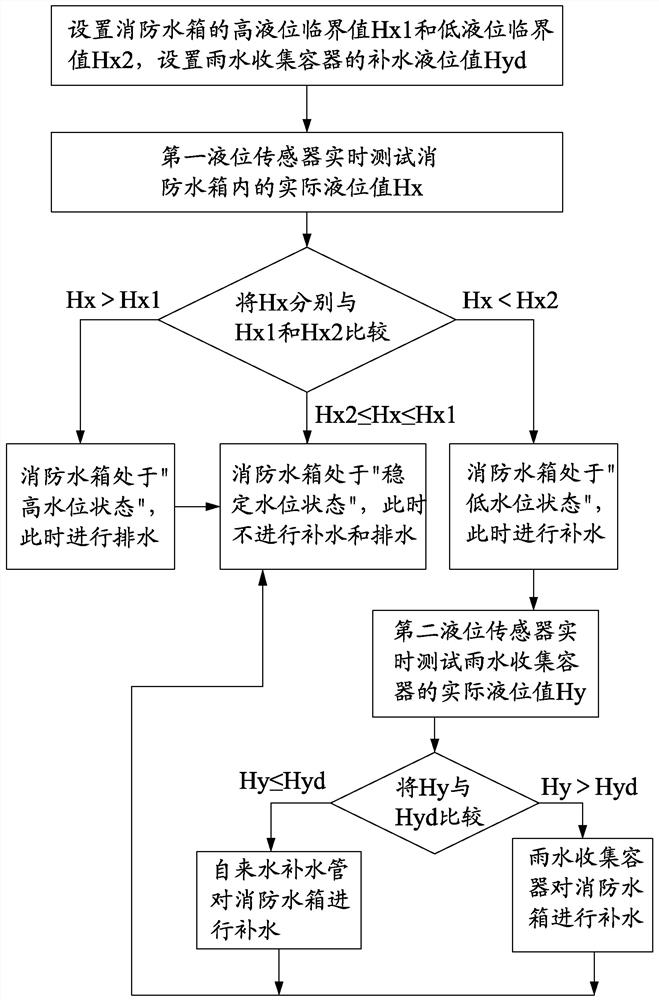

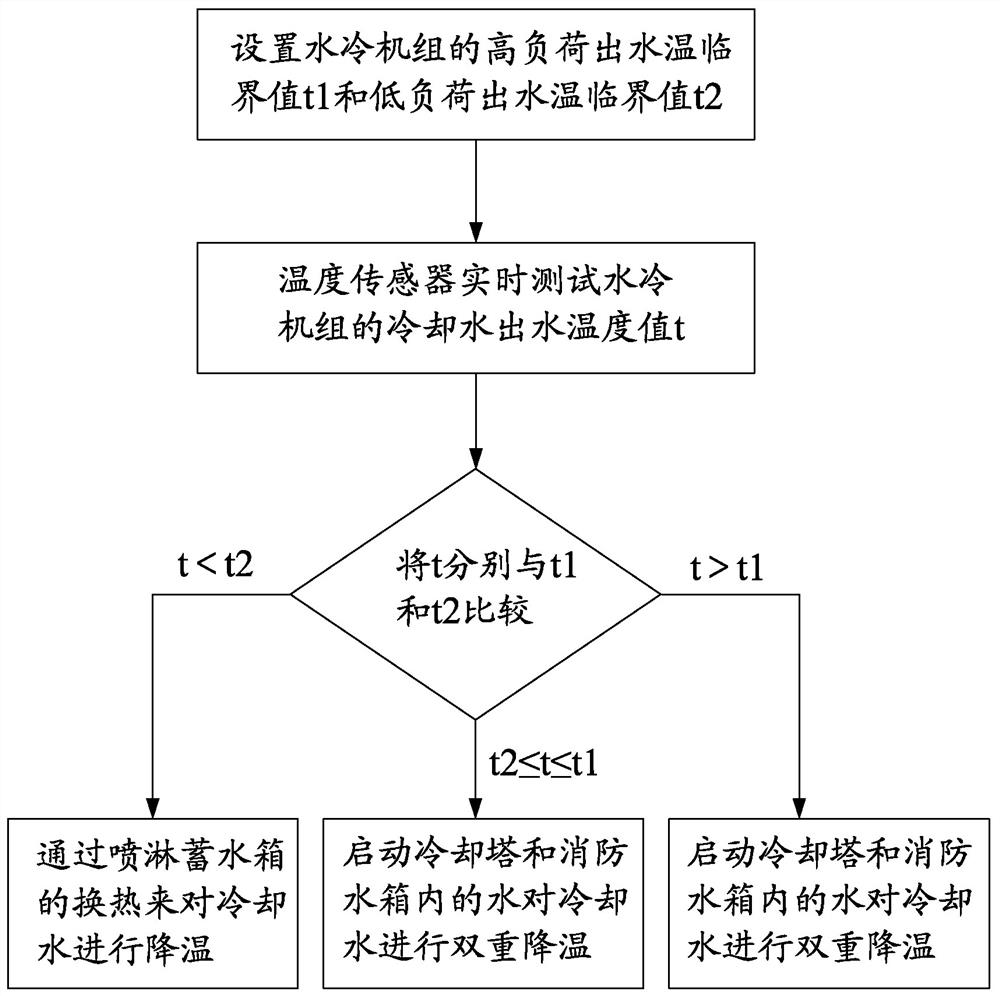

[0050] Please refer to figure 1 As shown, a preferred embodiment of a cooling tower device 100 with water replenishment and anti-scaling functions of the present invention, the cooling tower device includes a cooling water system 1, a rainwater collection and purification system 2, a control device 3, and a water cooling system. unit 4, a temperature sensor 5 and a fire water tank system 6;

[0051] The cooling water system 1 includes a cooling tower 11, a spray water storage tank 12, a variable frequency spray water pump 13 and a cooling water pump 14; the top of the cooling tower 11 is connected to the water cooling tower through a cooling tower return pipe 15. The water outlet side of the unit 4 is connected, and a first solenoid valve 151 is provided at the water outlet end of the cooling tower return pipe 15. When the first solenoid valve 151 is opened, the cooling water from the water cooling unit 4 can be cooled by cooling The tower return pipe 15 is sent to the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com