Special Cat-5e cable structure for aerospace and preparation method of cable structure

A technology of aerospace and cable structure, which is applied in the field of aerospace and super-category five network cables. It can solve the problems of reducing the carrying capacity of aircraft, high density of polyfluoroethylene propylene, and low temperature resistance of polyethylene, so as to enhance the oxidation resistance of conductors. , weight reduction, and signal loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

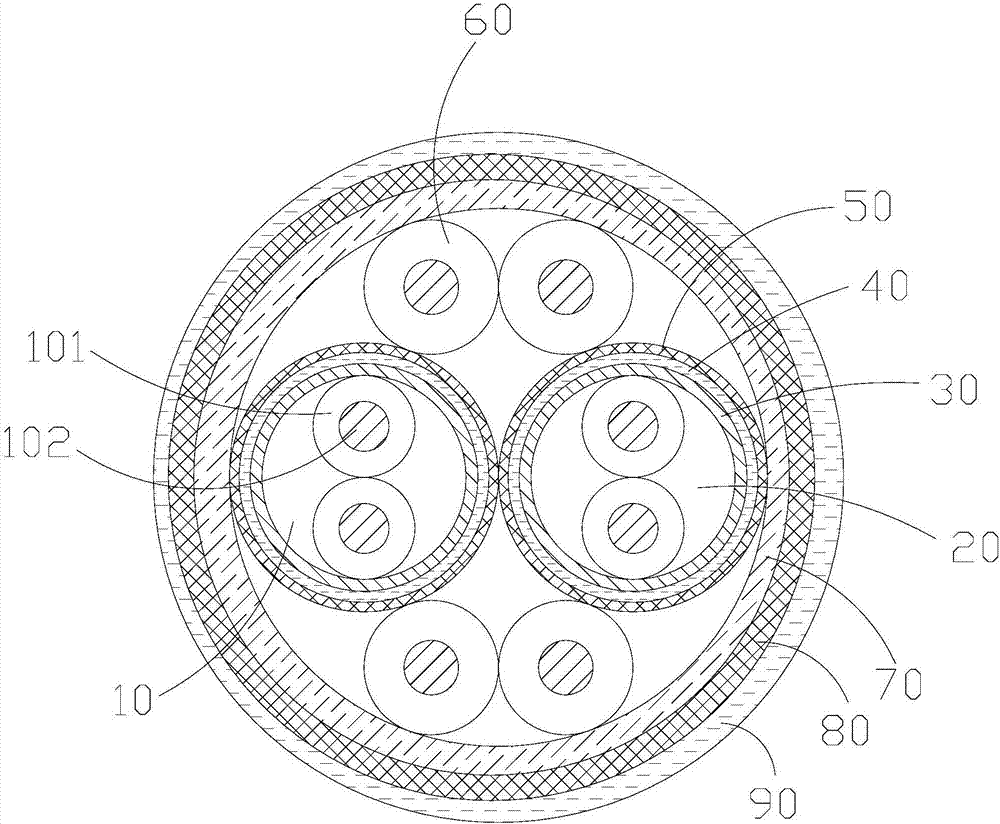

[0048] refer to figure 1, the present invention provides a special category five super cable structure for aerospace, including: white and blue pair twisted tape core; white orange twisted pair tape core; also includes 2 to 4 control wires 60; the three are twisted and The main structure of the cable is formed, and the twisting direction is right; wherein, the innermost layers of the white and blue twisted tape cores and the white and orange twisted tape cores are respectively: the first pair of cores 10, the second pair of cores 20. The first pair of wire cores 10 and the second pair of wire cores 20 are specifically the two insulated wire cores of white and blue should be twisted back to the left, and the two insulated wire cores of white and orange should be back twisted. twisted to the left; the conductor core insulation layer 101 of the white insulated wire core, the blue insulated wire core, and the orange insulated wire core is respectively white, blue, and orange; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com