Dye-sensitized solar cell photo anode and preparation method thereof

A technology for solar cells and dye sensitization, applied in the field of dye-sensitized solar cells, can solve problems such as cost, and achieve the effects of facilitating regulation and a simple and easy production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Using F127 [trade name: Pluronics is a water-soluble polyoxyethylene-polyoxypropylene-polyoxyethylene (PEO-PPO-PEO) three-stage copolymer] as a pore-forming agent, isopropyl titanate As a titanium source to prepare the precursor solution required for the photoanode, the specific steps include:

[0049] a) Add 22g (27.5ml) of absolute ethanol into 1.26g of pore-forming agent F127, stir evenly, and mark it as solution A;

[0050] b) Mix 3.36g of 37% hydrochloric acid solution with 1.5g of aqueous solution, marked as solution B;

[0051] c) Mix solutions A and B, stir until uniform, and mark it as solution C;

[0052] d) Slowly add 1.68 g of isopropyl titanate solution to the stirring solution C with a dropper, continue stirring for 2 hours until it becomes clear, and mark it as solution D, which is the precursor solution we need to prepare the photoanode ;

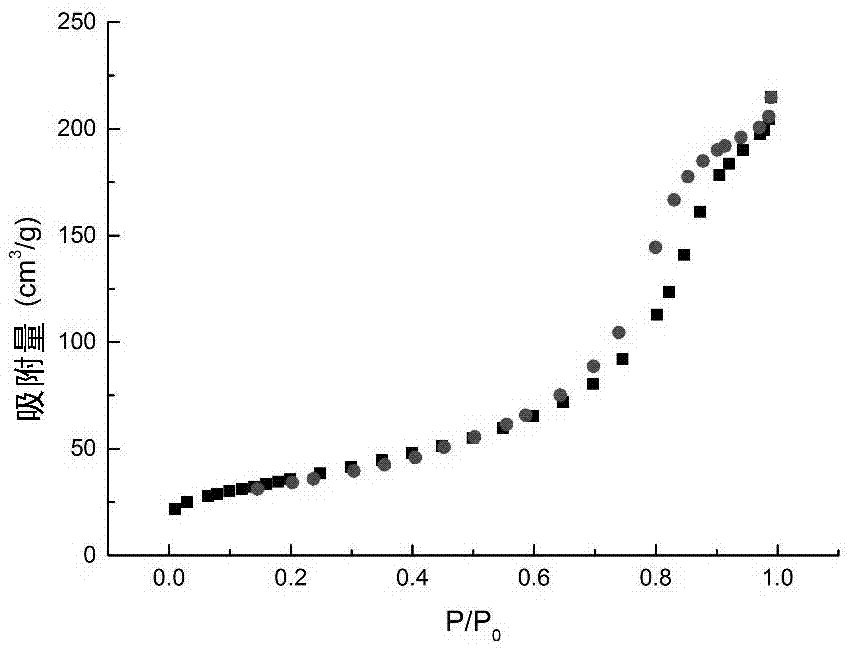

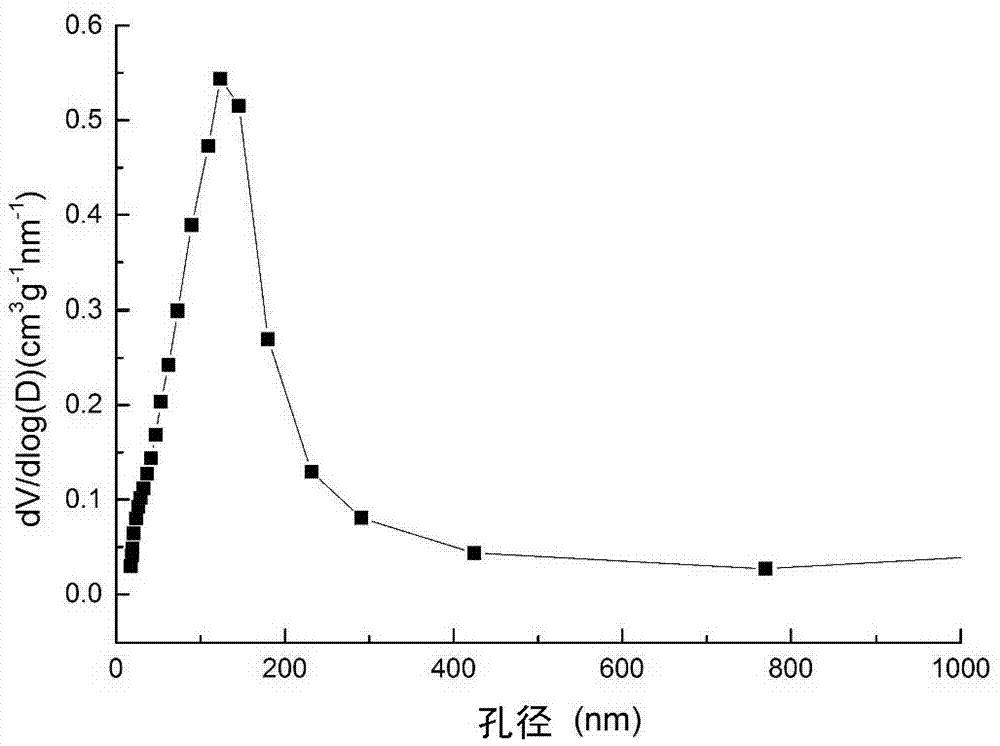

[0053] e) drying the solution D for sample preparation, figure 2 is the pore adsorption curve that charact...

Embodiment 2

[0076] Using P123 as a pore-forming agent, titanium tetrachloride and isopropyl titanate as a titanium source to prepare the precursor solution required for the photoanode, the specific steps include:

[0077]a) Add 1 g of pore-forming agent P123 to 20 g (25 ml) of absolute ethanol, stir for 30 min until uniform and clear, and mark it as solution A;

[0078] b) Slowly add 0.6 g (350 μl) of titanium tetrachloride with a pipette gun under stirring, and continue stirring until clarification;

[0079] c) Slowly add 1.7 g of isopropyl titanate with a pipette gun under stirring until it becomes clear, which is recorded as solution B; solution B is the precursor solution we need to prepare the photoanode.

[0080] (2) Using a pulling film machine to do fluorine (F) tin dioxide (SnO 2 ) transparent conductive glass (hereinafter referred to as FTO glass) made a single layer of mesoporous titanium dioxide (TiO 2 ):

[0081] a) Select a piece of FTO with a single area of 1.5cm*2.5cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com