Preparation method of trans-organic-inorganic hybrid perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of ITO electrode corrosion, perovskite stability and efficiency effects, etc., and achieve the effects of optimizing photoelectric conversion efficiency, improving conversion efficiency and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

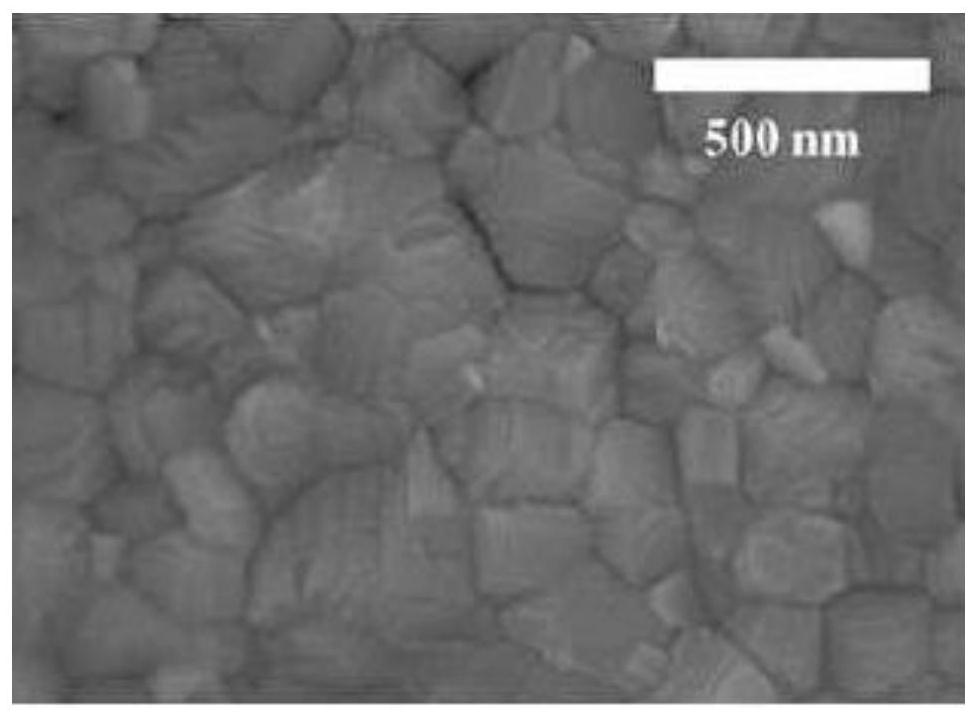

Image

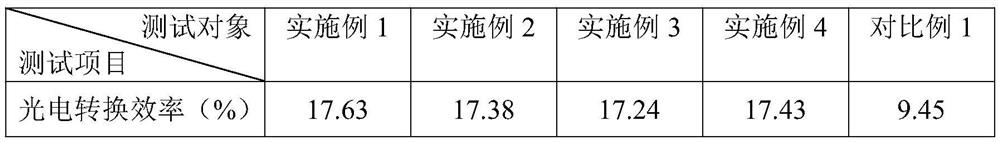

Examples

Embodiment 1

[0024] A method for preparing a trans-organic-inorganic hybrid perovskite solar cell, specifically comprising the following steps:

[0025] S1: Add ITO conductive glass deionized water, then add Alconox lotion powder, heat to 80°C to dissolve the lotion, perform ultrasonication for 30min, then ultrasonically wash with deionized water for 10 times, and finally use acetone and ethanol in sequence They were ultrasonically washed for 25 minutes, dried at 80°C for 30 minutes, and set aside.

[0026] S2: Add PEDOT (poly(3,4-ethylenedioxythiophene)): agarose to dimethyl sulfoxide and N,N-dimethylformamide, and then place the ITO substrate on the homogenizer , the PEDOT: agarose solution was spin-coated on the ITO substrate, and then annealed at 100 ° C for 10 min to form a 10 nm thick PEDOT: agarose film, in which PEDOT (poly(3,4-ethylenedioxythiophene)) and The addition ratio of agarose is 40%:60%; the volume ratio of dimethyl sulfoxide and N,N-dimethylformamide is 1:3.5.

[0027]...

Embodiment 2

[0033] A method for preparing a trans-organic-inorganic hybrid perovskite solar cell, specifically comprising the following steps:

[0034] S1: Add ITO conductive glass deionized water, then add Alconox lotion powder, heat to 90°C to dissolve the lotion, perform ultrasonication for 50min, then ultrasonically wash with deionized water for 16 times, and finally use acetone and ethanol in sequence They were ultrasonically washed for 30 minutes, dried at 90°C for 30 minutes, and set aside.

[0035]S2: Add PEDOT (poly(3,4-ethylenedioxythiophene)): agarose to dimethyl sulfoxide and N,N-dimethylformamide, and then place the ITO substrate on the homogenizer , the PEDOT: agarose solution was spin-coated on the ITO substrate, and then annealed at 120 ° C for 15 min to form a 13 nm thick PEDOT: agarose film, in which PEDOT (poly(3,4-ethylenedioxythiophene)) and The addition ratio of agarose is 45%:55%; the volume ratio of dimethyl sulfoxide and N,N-dimethylformamide is 2:5.

[0036] S2...

Embodiment 3

[0042] A method for preparing a trans-organic-inorganic hybrid perovskite solar cell, specifically comprising the following steps:

[0043] S1: Add ITO conductive glass deionized water, then add Alconox lotion powder, heat to 85°C to dissolve the lotion, perform ultrasonication for 40min, then ultrasonically wash with deionized water for 12 times, and finally use acetone and ethanol in sequence They were ultrasonically washed for 25 minutes, dried at 85°C for 30 minutes, and set aside.

[0044] S2: Add PEDOT (poly(3,4-ethylenedioxythiophene)): agarose to dimethyl sulfoxide and N,N-dimethylformamide, and then place the ITO substrate on the homogenizer , the PEDOT: agarose solution was spin-coated on the ITO substrate, and then placed at 110 ° C for 12 minutes to form a 11nm thick PEDOT: agarose film, in which PEDOT (poly(3,4-ethylenedioxythiophene)) and The addition ratio of agarose is 48%:52%; the volume ratio of dimethyl sulfoxide and N,N-dimethylformamide is 1.4:4.2.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com