Water-based grinding fluid suspension additive

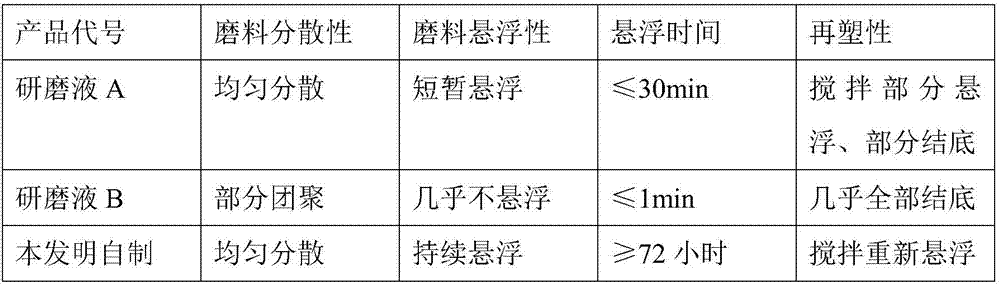

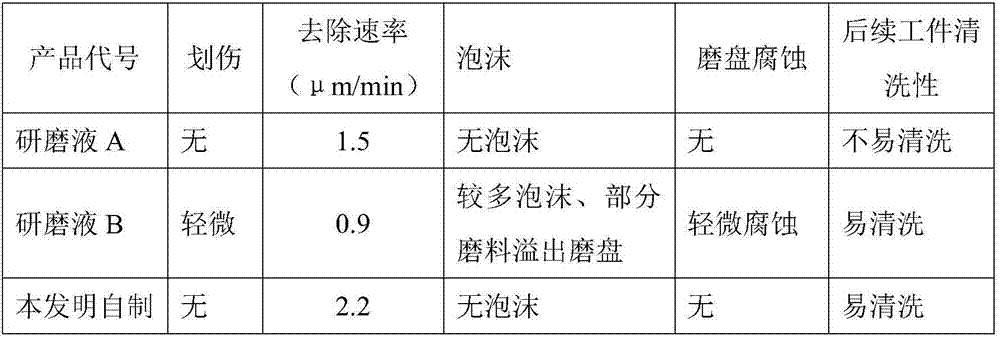

An additive and grinding fluid technology, applied in the field of water-based grinding fluid suspension additives, can solve the problems of high abrasive loss of grinding fluid, reduced grinding and polishing efficiency, slow grinding speed, etc. Effect of Grinding Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 3 parts of suspension stabilizer SF-1, 5 parts of humectant VK-N80, 8 parts of tripropylene glycol methyl ether, 76 parts of alkaline electrolyzed water, 8 parts of ammonium polyphosphate, among which ammonium polyphosphate with a degree of polymerization of 10 is selected.

[0028] The preparation method of above-mentioned embodiment:

[0029] 1) Add the suspension stabilizer SF-1 into the alkaline electrolyzed water, fully stir and swell with a tissue homogenizer at a speed of 4000r / min, and obtain a transparent gel for use;

[0030] 2) Dissolve humectant VK-N80 and ammonium polyphosphate with alkaline electrolyzed water to obtain a solution for later use;

[0031] 3) Slowly add the material obtained in step 1) into tripropylene glycol methyl ether by using a nano-disperser while adding and dispersing at room temperature, and fully stir and disperse;

[0032] 4) Preheat the material obtained in the above step 3) to 78°C by microwave, and slowly add the material in st...

Embodiment 2

[0034] 5 parts of suspension stabilizer SF-1, 1 part of humectant VK-N80, 7 parts of tripropylene glycol methyl ether, 66 parts of alkaline electrolyzed water, 6 parts of ammonium polyphosphate, and 15 parts of triethanolamine. Among them, ammonium polyphosphate with a degree of polymerization of 6 is selected.

[0035] The preparation method of above-mentioned embodiment:

[0036] 1) Add the suspension stabilizer SF-1 into the alkaline electrolyzed water, fully stir and swell with a tissue homogenizer at a speed of 4000r / min, and obtain a transparent gel for use;

[0037] 2) Dissolve humectant VK-N80, ammonium polyphosphate, and triethanolamine in alkaline electrolyzed water to obtain a solution for later use;

[0038] 3) Slowly add the material obtained in step 1) into tripropylene glycol methyl ether by using a nano-disperser while adding and dispersing at room temperature, and fully stir and disperse;

[0039] 4) Preheat the material obtained in the above step 3) to 75°C...

Embodiment 3

[0041] 2 parts of suspension stabilizer SF-1, 4 parts of humectant VK-N80, 5 parts of tripropylene glycol methyl ether, 81 parts of alkaline electrolyzed water, 5 parts of ammonium polyphosphate, 2 parts of thickener ACRYSOL TT-935, lubricant MPEG -600 0.5 parts, defoamer Surfynol DF-750.5 parts. Among them, ammonium polyphosphate with a degree of polymerization of 18 is selected.

[0042] The preparation method of above-mentioned embodiment:

[0043] 1) Add the suspension stabilizer SF-1 and the thickener ACRYSOL TT-935 into the alkaline electrolyzed water, and use a tissue homogenizer to fully stir and swell at a speed of 4000r / min to obtain a transparent gel for use;

[0044] 2) Dissolve humectant VK-N80, ammonium polyphosphate, lubricant MPEG-600, and defoamer Surfynol DF-75 in alkaline electrolyzed water to obtain a solution for later use;

[0045] 3) Slowly add the material obtained in step 1) into tripropylene glycol methyl ether by using a nano-disperser while adding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com