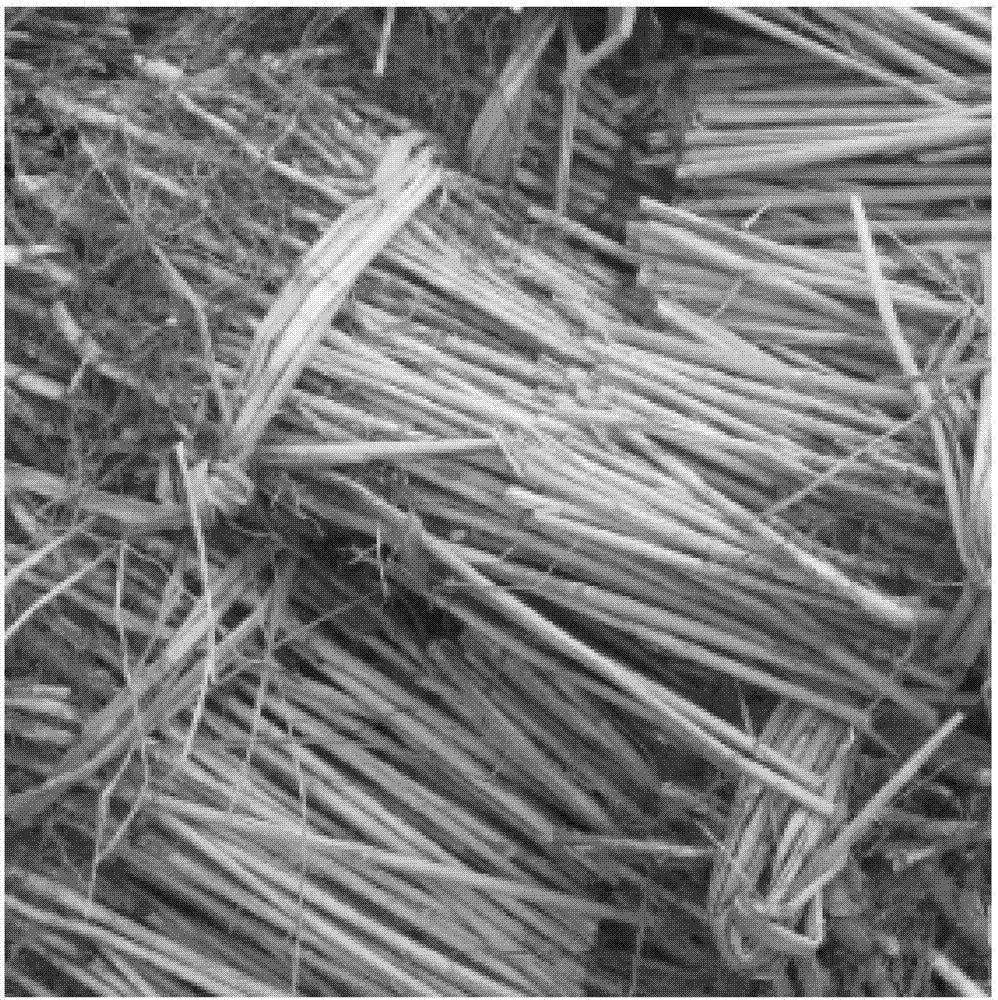

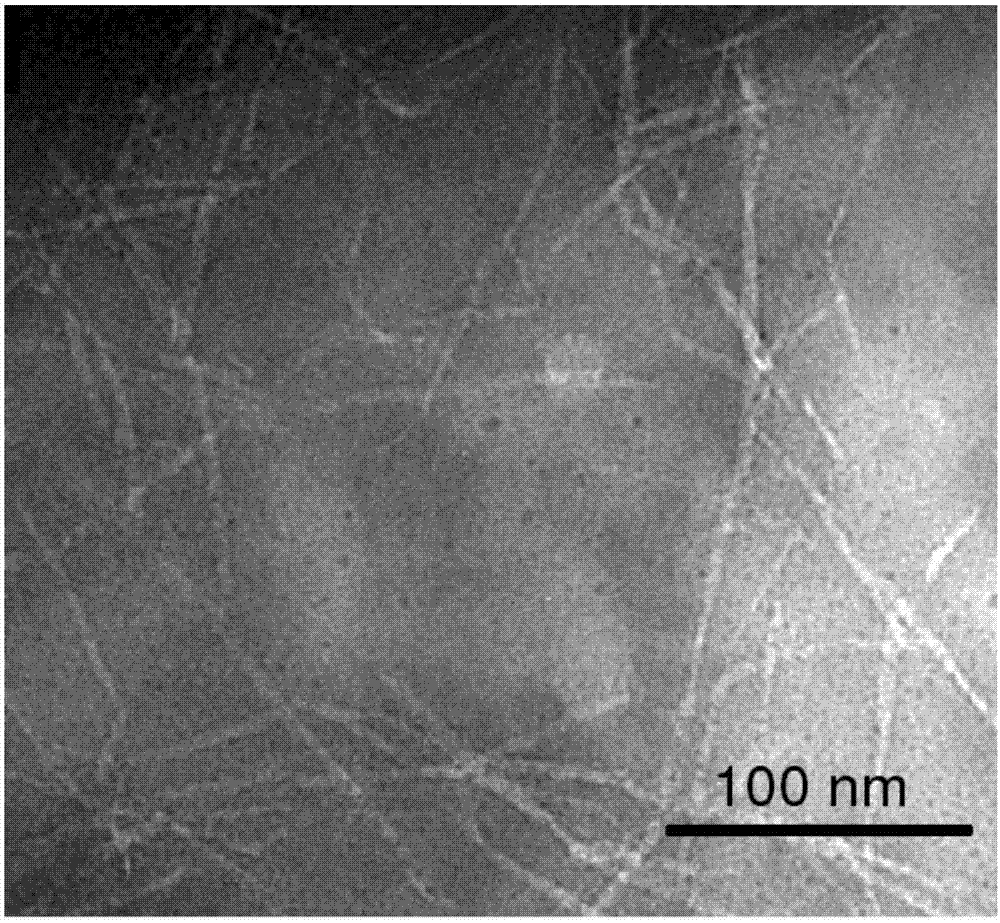

Reed stem cellulose nano-fiber and preparation method thereof

A cellulose and nanofilament technology, applied in the field of nanomaterials, to achieve the effect of improving physical properties, high aspect ratio, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing reed stem cellulose nanofilaments is prepared by the following steps.

[0025] Firstly, a pretreatment step: the reed stem is hydrolyzed and then dried to obtain a pretreated reed stem. Preferably, cut reed stems are dispersed in water, treated at a temperature of 120° C. to 180° C. and a pressure of 1.3 to 1.6 MPa for 60 to 240 minutes, and dried to obtain a pretreated reed stem.

[0026] Furthermore, in a preferred embodiment of the present invention, the reed stem is cut into small sections of 1-3 cm, and the reed stem is cut into an appropriate length, which is convenient for subsequent operations and consumes less energy.

[0027] Further, in a preferred embodiment of the present invention, in the pretreatment step, the solid-liquid ratio of reed stems and water is 1:6-10 g / mL.

[0028] Further, in a preferred embodiment of the present invention, the drying is air-drying, which may be natural air-drying or mechanical air-drying. Natural air...

Embodiment 1

[0046] A kind of reed stem cellulose provided in this embodiment is prepared according to the following steps::

[0047] First, take 100g of reed stems, cut them into 1-3cm segments, wash them with distilled water, transfer them to a reaction kettle, add 600mL of distilled water, raise the temperature to 120°C, and treat them for 240min at a pressure of 1.3MPa. Collect the pretreated reed stems. Air dry.

[0048] Then, take 1000g of absolutely dry reed stem pretreatment, add in 1.6(wt)% NaOH and 0.05(wt)% anthraquinone mixed solution of 10L, 25 ℃ and stir for 60min and then transfer to the electrothermal rotary reactor, Raise the temperature to 155° C., react for 90 minutes, continue to keep warm for 50 minutes, wash with distilled water, and remove lignin to obtain reed stem heddle cellulose.

[0049] Next, weigh 10g of reed stem heddle cellulose and disperse it in 100mL of distilled water, add 20mL of 30wt% H 2 o 2 The solution was heated and stirred in a water bath at 40...

Embodiment 2

[0053] A kind of reed stem cellulose provided in this embodiment is prepared according to the following steps::

[0054] First, take 100g of reed stems, cut them into 1-3cm segments, wash them with distilled water, transfer them to a reaction kettle, add 1000mL of distilled water, heat up to 180°C, and press at 1.6MPa for 60 minutes to collect the pretreated reed stems. Air dry.

[0055] Then, take 1000g of absolutely dry reed stem pretreatment, add in 20L of 2(wt)% NaOH and 0.1(wt)% anthraquinone mixed solution, transfer to the electrothermal rotary reaction kettle after stirring at 35°C for 20min, Raise the temperature to 160°C, react for 45 minutes, continue to keep warm for 90 minutes, wash with distilled water, and remove lignin to obtain reed stem heddle cellulose.

[0056] Next, weigh 10g of reed stem heddle cellulose and disperse it into 50mL of distilled water, add 20mL of 30wt% H 2 o 2 The solution was heated and stirred in a water bath at 60° C. to react for 60 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com