Mixed working medium cascade power generation and remaining cooling capacity output system and method utilizing liquefied natural gas (LNG) cold energy

A technology of mixing working fluid and output system, applied in the direction of combined combustion mitigation, machine/engine, steam engine installation, etc., can solve the problems of complex structure, influence of temperature and pressure deviation, huge system, etc., to improve heat exchange matching performance and avoid high The effect of reducing damage and improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

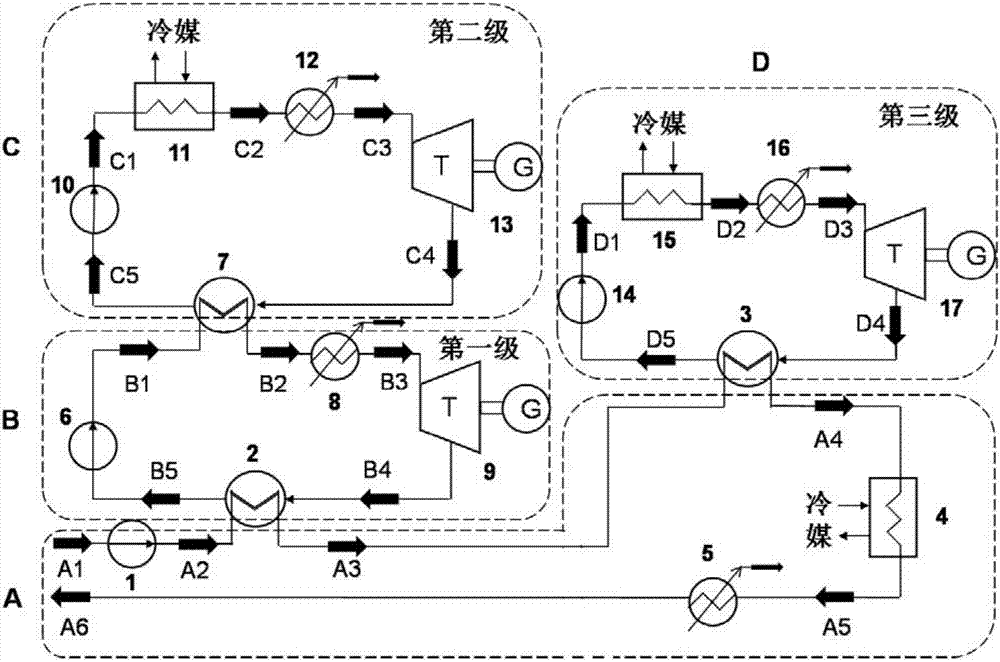

[0085] A mixed working fluid cascade power generation and residual cooling capacity output system using LNG cold energy, the process flow is as follows figure 1 As shown, it includes LNG vaporization side A, the first-stage ternary mixed refrigerant Rankine cycle B, the second-stage ternary mixed refrigerant Rankine cycle C, and the third-stage two-element mixed refrigerant Rankine cycle D. .

[0086] The molar composition of liquefied natural gas (LNG) at the receiving station is simplified as follows: 93% methane, 4% ethane, 1.5% propane, 1% isobutane, 0.1% isopentane, and 0.4% nitrogen; LNG used for cold energy power generation The evaporation capacity is 191t / h, and the first-stage ternary mixed working medium in Rankine Cycle B is selected as the first-stage circulating medium, which is composed of methane, ethylene and propane (the mass percentage of the three is 0.21:0.29 :0.50), the flow rate is 128.7t / h; the second-stage circulating medium in the second-stage ternary...

Embodiment 2

[0095] A mixed working fluid cascade power generation and residual cooling capacity output system using LNG cold energy, the process flow is as follows figure 1 As shown, it includes LNG vaporization side A, the first-stage ternary mixed refrigerant Rankine cycle B, the second-stage ternary mixed refrigerant Rankine cycle C, and the third-stage two-element mixed refrigerant Rankine cycle D. .

[0096]The molar composition of liquefied natural gas (LNG) at the receiving station is simplified as follows: 93% methane, 4% ethane, 1.5% propane, 1% isobutane, 0.1% isopentane, and 0.4% nitrogen; LNG used for cold energy power generation The evaporation capacity is 191t / h, and the first-stage ternary mixed working medium in Rankine Cycle B is selected as the first-stage circulating medium, which is composed of methane, ethylene and propane (the mass percentage of the three is 0.18:0.39 :0.43), the flow rate is 122.8t / h; in the second-stage ternary mixed working medium Rankine cycle C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com