Method for evaluating interfiber bonded area of high-yield pulp by using confocal laser scanning microscope (CLSM)

A high-yield pulp and bonding area technology, applied in the field of pulp and papermaking, can solve the problems of undetected pulp fiber actual bonding area, no detection instrument and operating parameters, introduction of problems and their solutions, etc., to achieve high accuracy, Good adaptability, avoid interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

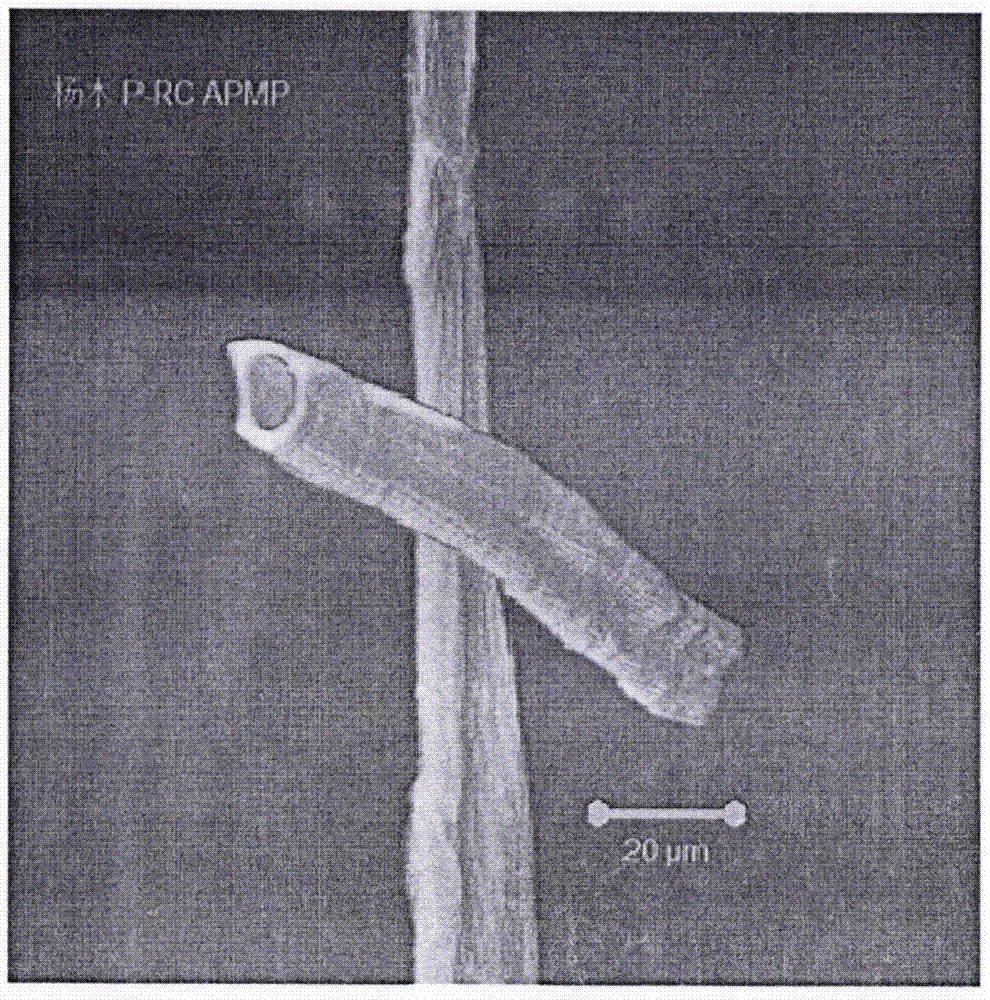

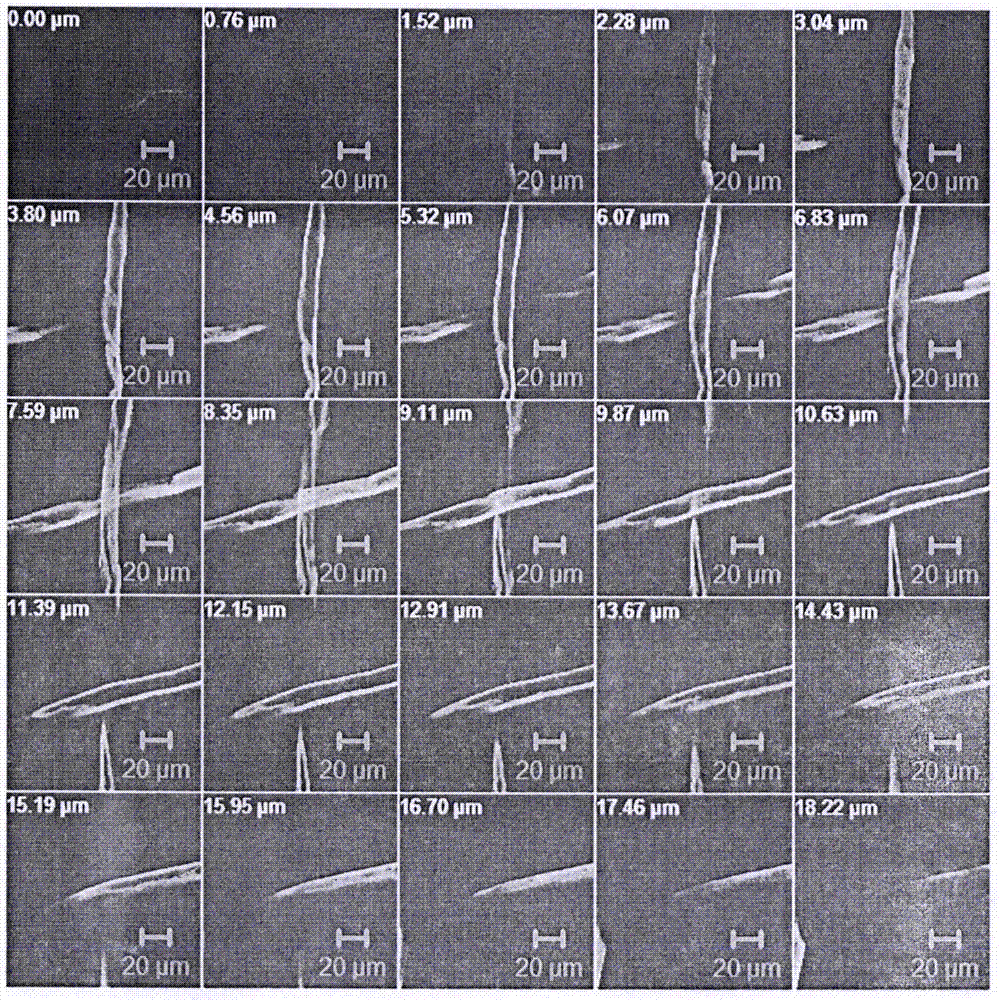

[0063] Take 60g of poplar P-RC APMP pulp produced by a certain factory and soak it in 1L of deionized water for 4 hours; the pulp after soaking will be depotentized. The pulp after submergence is dissociated with a standard fiber dissociation machine, and the dissociated pulp is classified with a Bauer sieve using 30, 50, 100 and 200-day screens, and the sieves are collected. The pulp fibers of the four fractions obtained by dividing; measure the solid content after equalizing the moisture, and set aside;

[0064] Take an appropriate amount of R30 fraction poplar P-RC APMP pulp fibers obtained by the above sieving and soak in deionized water for one week; use 5×10 -5 mol / L acridine orange solution dyeing, the specific dyeing method is: Weigh the wet slurry with a dry weight of 0.2g, put it into a 50mL glass bottle wrapped with tinfoil, add 40mL fluorescent dye solution to the glass bottle, add an appropriate amount of Cover the glass beads with a rubber stopper and shake even...

Embodiment 2

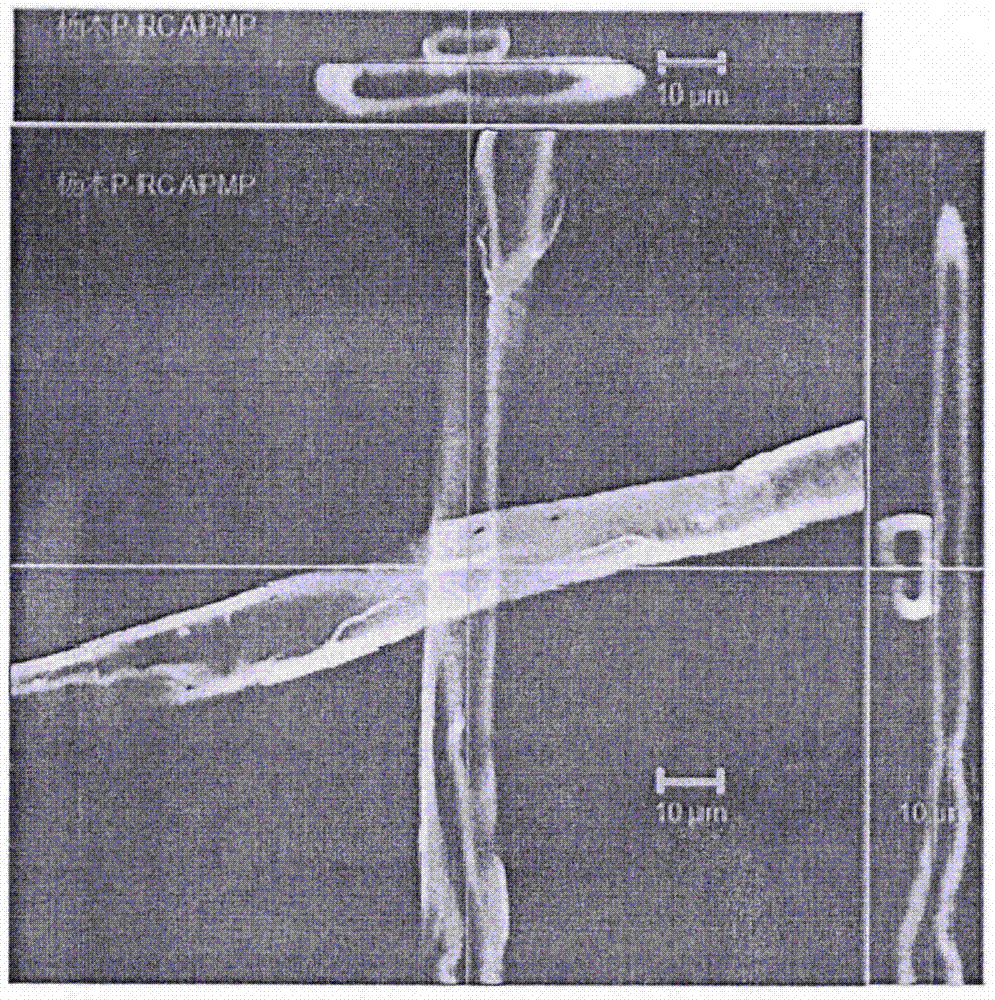

[0077] Take 60g of poplar P-RC APMP pulp produced by a certain factory and soak it in 1L of deionized water for 4 hours; the pulp after soaking is subjected to delamination treatment. The pulp after submergence is dissociated with a standard fiber dissociation machine, and the dissociated pulp is classified with a Bauer sieve using 30, 50, 100 and 200 mesh screens, and collected and sieved The pulp fiber of four fractions that obtains; Measure solid content after equalizing moisture, standby:;

[0078] Take an appropriate amount of P30 / R50 fraction poplar P-RC APMP pulp fibers obtained by the above screening and soak in deionized water for one week: use 6×10 5 mol / L acridine orange solution dyeing, the specific dyeing method is: Weigh the wet slurry with a dry weight of 0.2g, put it into a 50mL glass bottle wrapped with tinfoil, add 40mL fluorescent dye solution to the glass bottle, add an appropriate amount of Cover the glass beads with a rubber stopper and shake evenly for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com