A method for preparing monophenolic compounds by catalyzing lignin degradation with ammonia complexes

A technology of ammonia complexes and lignin, which is applied in the field of preparing monophenolic compounds by using ammonia complexes to catalyze the degradation of lignin, can solve the problems of complicated product purification operations, poor selectivity of degradation products, and low product yields, and achieve improved Effect of product selectivity, increased contact sites, high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

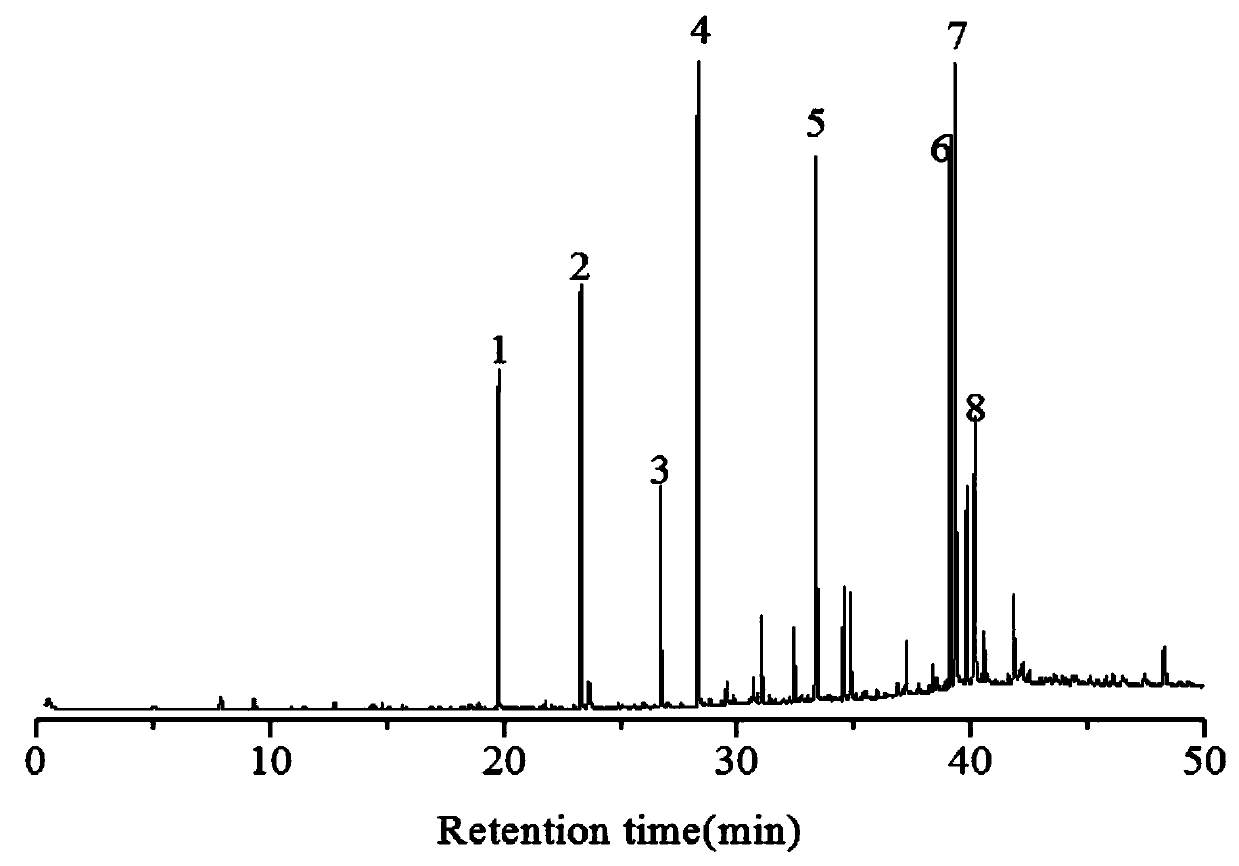

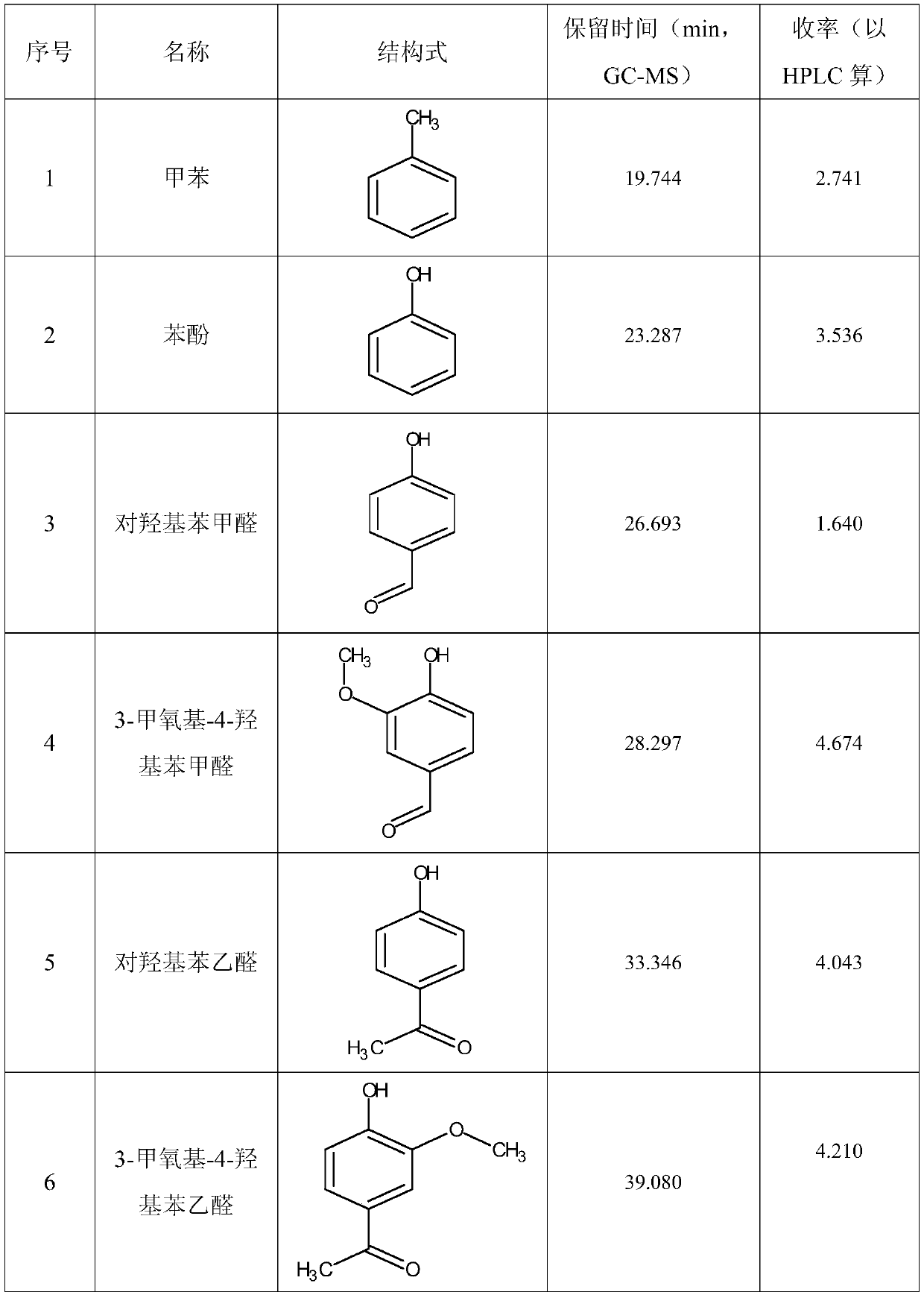

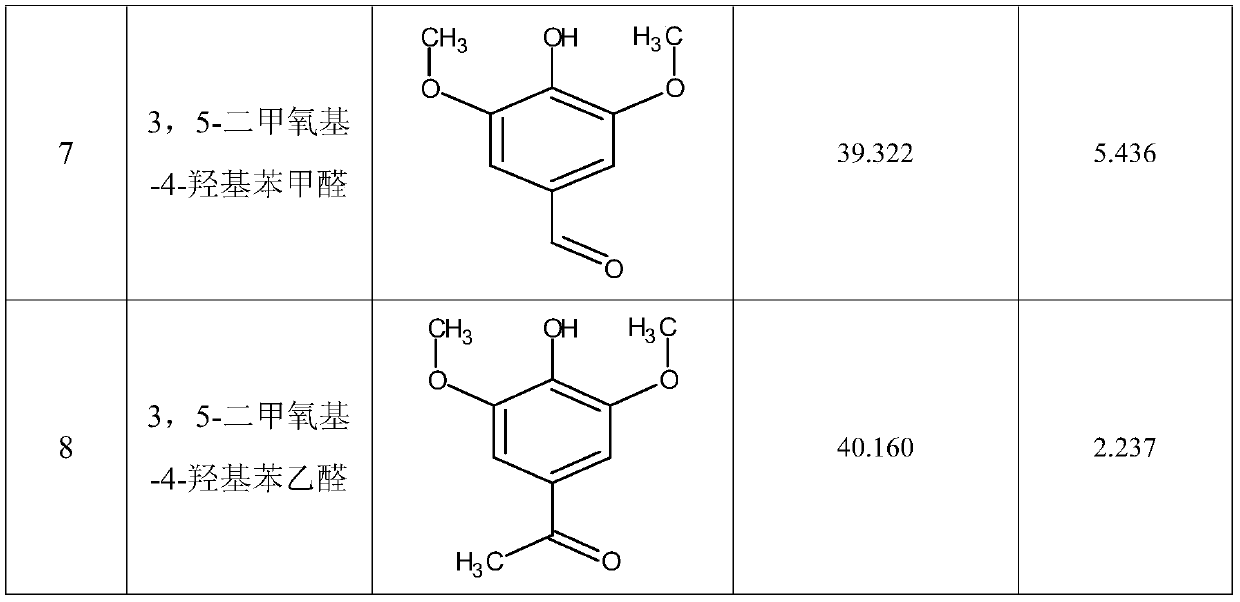

Image

Examples

Embodiment 1

[0029] (1) In parts by weight, 5 parts of bagasse lignin, 0.5 part of sodium hydroxide, 8 parts of hydrogen peroxide aqueous solution with a mass fraction of 4:1 in a weight ratio of 30% and a mass fraction of 5% The mixture of zinc chlorate aqueous solution, 0.15 parts of zinc acetate, 4 parts of ammonia solution with a mass fraction of 25% and 100 parts of deionized water are mixed, poured into a high-pressure reactor, quickly sealed and stirred evenly at a speed of 300 r / min. Forms a clear solution;

[0030] (2) Continue to maintain a stirring speed of 300r / min, heat the high-pressure reactor to 150°C, stop the reaction after 120min of reaction, and naturally cool to room temperature to obtain a primary degradation product;

[0031] (3) Adjust the pH value of the primary degradation product to 2 with an aqueous sulfuric acid solution with an acid mass fraction of 10%, seal the high-pressure reactor, heat to 120° C., stop the reaction after reacting for 10 minutes, and natur...

Embodiment 2

[0039] (1) In parts by weight, 1 part of eucalyptus lignin, 0.5 part of potassium hydroxide, 0.5 part of hydrogen peroxide aqueous solution with a mass fraction of 3:1 in a weight ratio of 30% and a mass fraction of 5% The mixture of zinc chlorate aqueous solution, 0.1 part of zinc oxide, 1 part of ammonia solution with a mass fraction of 5% ammonia solution and 100 parts of deionized water are mixed, poured into a high-pressure reactor, quickly sealed and stirred at a speed of 300r / min Uniform, forming a clear solution;

[0040] (2) Continue to maintain a stirring speed of 300r / min, heat the high-pressure reactor to 120°C, stop the reaction after 100min of reaction, and naturally cool to room temperature to obtain a primary degradation product;

[0041] (3) After adjusting the pH value of the primary degradation product to 2 with a sulfuric acid aqueous solution with a mass fraction of 10%, seal the high-pressure reactor, heat to 100° C., stop the reaction after 10 minutes of...

Embodiment 3

[0045] (1) In parts by weight, 2 parts of bagasse lignin, 0.8 parts of sodium hydroxide, 4 parts of hydrogen peroxide aqueous solution with a mass fraction of 2:1 in a weight ratio of 30% and a mass fraction of 5% The mixture of zinc chlorate aqueous solution, 0.15 parts of zinc sulfate, 2 parts of ammonia solution with a mass fraction of 15% of ammonia solution and 100 parts of deionized water are mixed, poured into a high pressure reactor, quickly sealed and stirred at a speed of 300r / min Uniform, forming a clear solution;

[0046] (2) Continue to maintain a stirring speed of 300r / min, heat the high-pressure reactor to 135°C, stop the reaction after 150min of reaction, and naturally cool to room temperature to obtain a primary degradation product;

[0047] (3) After adjusting the pH value of the primary degradation product to 2.5 with an aqueous sulfuric acid solution with an acid mass fraction of 11%, seal the high-pressure reactor, heat to 105° C., stop the reaction after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com