Waterborne polyurethane resin for waterborne clothing leather base and preparation method thereof

A technology of water-based polyurethane and resin, which is applied in the direction of textiles and papermaking, etc., can solve the problems of water-based clothing leather base development limitations, poor clothing leather structure, poor air permeability, etc., to avoid pollution and human health hazards, soft hand feel, The effect of high fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

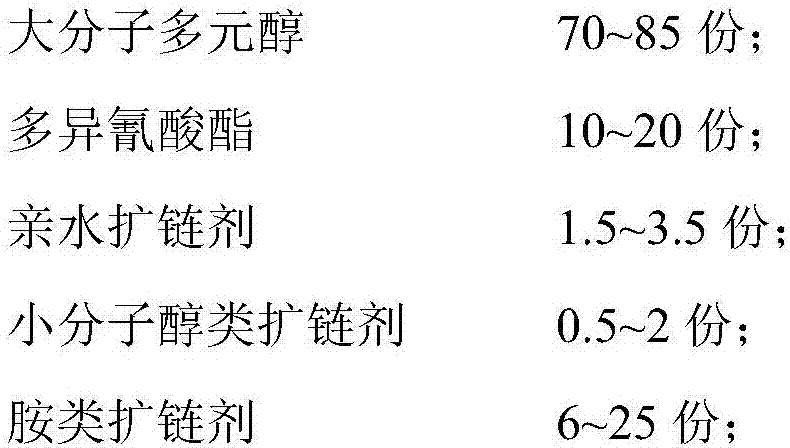

Method used

Image

Examples

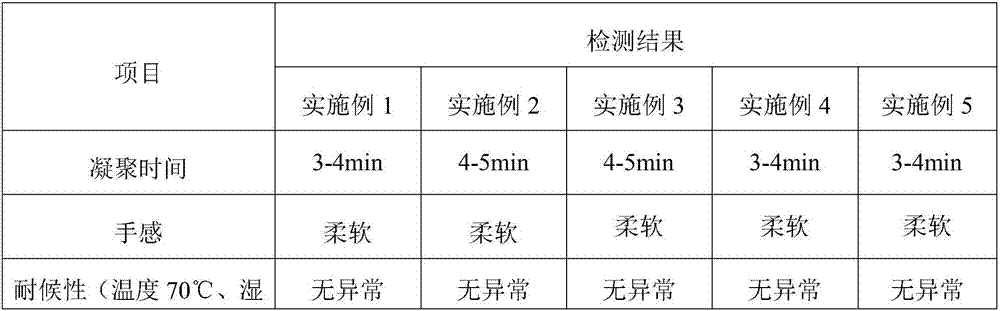

Embodiment 1

[0036] Dehydrate 80g of polytetrahydrofuran ether polyol (molecular weight: 3000) at 105°C for 1 hour, then cool down to 50°C, add 15g of toluene diisocyanate, raise the temperature to 90°C and keep it warm for 3 hours, measure the NCO content in two hours, and reach the theoretical value After cooling down to 50°C, add 2g of dimethylolbutyric acid and 1.5g of ethylene glycol to react at 80°C for 2h, cool down to 50°C, then add 0.2g of organic bismuth Coscat83 and 2ml of acetone to adjust the viscosity. React for 2.5 hours, measure the NCO content after the reaction is over, then cool down to 0°C, add 2.32g of triethylamine for neutralization, after neutralization for 30 minutes, add deionized water under high-speed shear, disperse for 2 minutes, and then slowly add 10g of poly Ether amine (molecular weight is 2000), the acetone in the system is distilled off under reduced pressure, promptly obtains waterborne polyurethane resin sample 1.

Embodiment 2

[0038] Dehydrate 78g of polyethylene oxide polyol (molecular weight: 3000) at 105°C for 1 hour, then cool down to 50°C, add 15g of isophorone diisocyanate, raise the temperature to 90°C and keep it warm for 3 hours, then measure NCO in two hours After reaching the theoretical value, cool down to 50°C, then add 2g of dimethylolbutyric acid and 1.5g of glycerin to react at 80°C for 2 hours, cool down to 50°C, then add 0.15g of organic bismuth 1610 and 2ml of acetone to adjust the viscosity, React at 70°C for 2.5h, measure the NCO content after the reaction is over, then cool down to 0°C, add 2.12g of triethylamine for neutralization, after neutralization for 30min, add deionized water under high-speed shear, disperse for 2min, then slowly add 20g of polyether amine (molecular weight: 2000), acetone in the system was distilled off under reduced pressure to obtain water-based polyurethane resin sample 2.

Embodiment 3

[0040] Dehydrate 75g of polyester ether polyol (molecular weight: 3000) at 105°C for 1 hour, then cool down to 50°C, add 15g of 1,6-hexamethylene diisocyanate, raise the temperature to 90°C and keep it warm for 3 hours, then measure the NCO content in two hours After reaching the theoretical value, cool down to 50°C, then add 2g of dimethylol octanoic acid, 1.5g of ethylene glycol to react at 80°C for 2h, cool down to 50°C, then add 0.2g of organic bismuth 2010 and 2ml of acetone to adjust the viscosity. React at 70°C for 2.5h, measure the NCO content at the end of the reaction, then cool down to 0°C, add 2.51g of triethylamine for neutralization, after neutralization for 30min, add deionized water under high-speed shearing, disperse for 2min, then slowly add 15g of polyetheramine (molecular weight: 2000), acetone in the system was distilled off under reduced pressure to obtain waterborne polyurethane resin sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com