A composition used for food-grade gear oil, a preparing method thereof, gear oil including the composition and a preparing method of the gear oil including the composition

A food-grade, gear oil technology, applied in the field of lubricating oil, can solve the problem of no uniform food-grade lubricating oil, and achieve the effects of excellent waterproof, stable performance, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

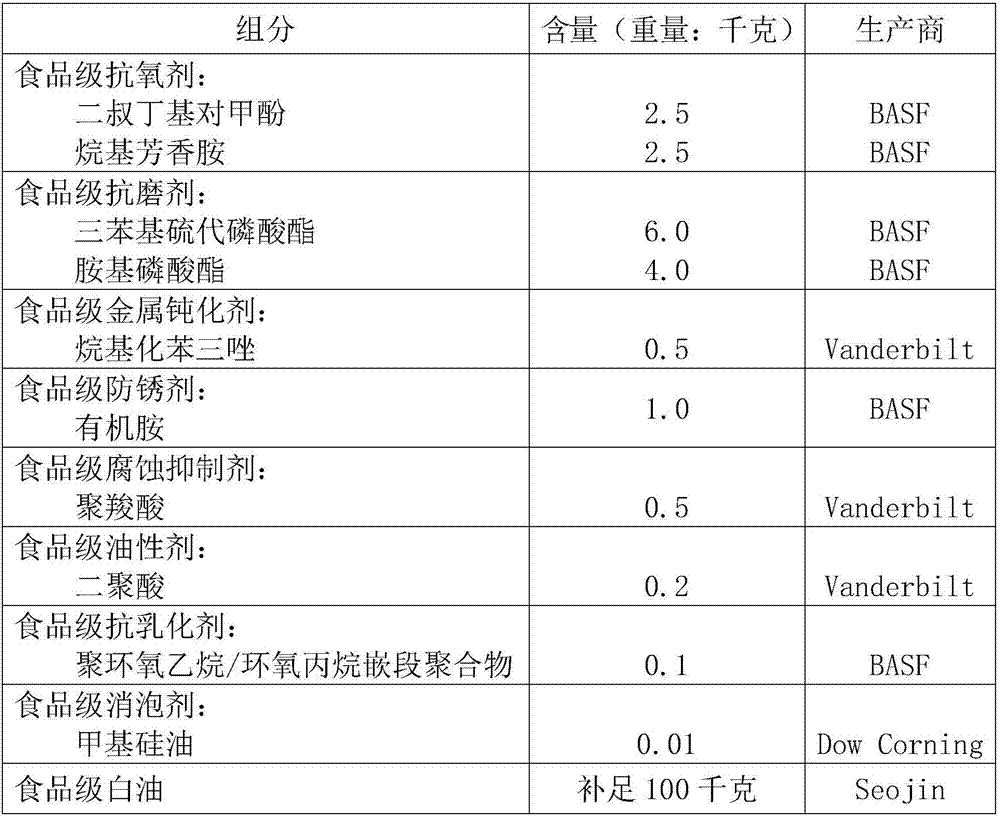

[0036] The composition of this composition that is used for food grade gear oil is as follows (in 100 kilograms, hereinafter the same):

[0037]

[0038] The preparation method of the composition that is used for food-grade gear oil, adopts the following steps:

[0039] (1-1) Add 30% of the weight of food-grade white oil into the blending kettle, and heat it to 30°C under normal pressure; under the premise of satisfying the amount of dissolved additives, adding a small amount of base oil can save heating time and improve production efficiency;

[0040](1-2) Add a food-grade anti-wear agent to the food-grade white oil obtained by heating in step (1-1) while stirring, and stir and mix at 57° C. for 20 minutes under normal pressure;

[0041] (1-3) Add food-grade antioxidant, food-grade metal deactivator, food-grade rust inhibitor, food-grade corrosion inhibitor, food-grade oily agent while stirring in the mixture obtained in step (1-2) , food-grade anti-emulsifier, stirring a...

Embodiment 12

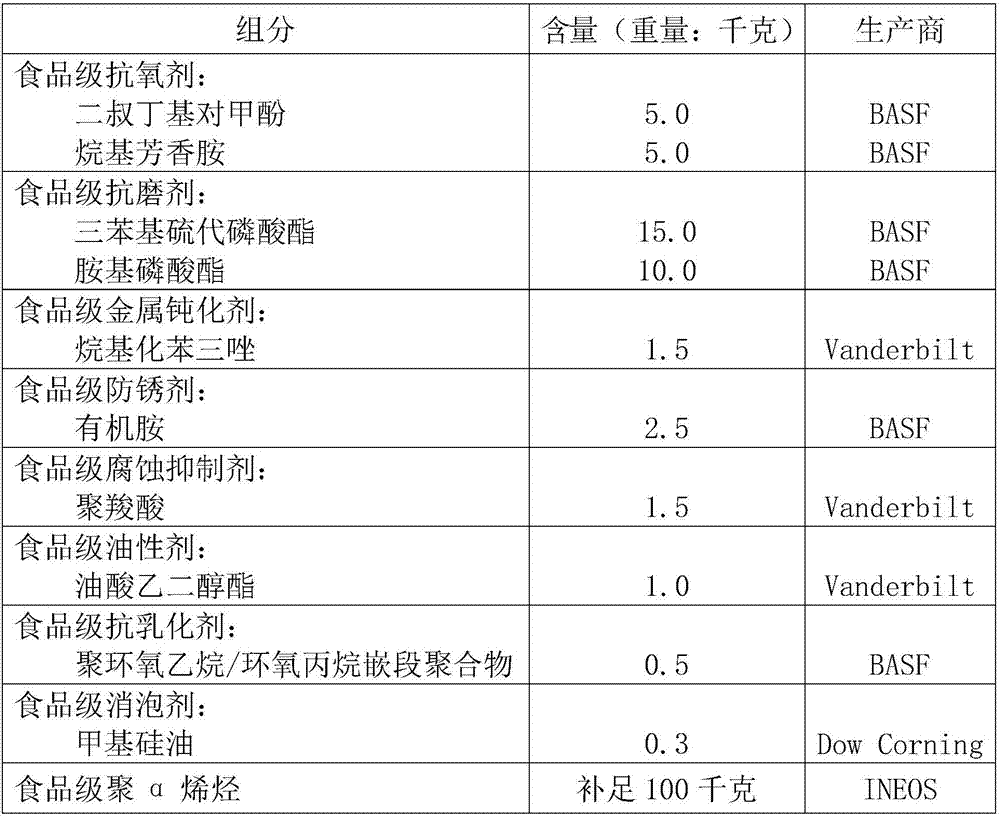

[0044]

[0045] The preparation method of the composition that is used for food-grade gear oil, adopts the following steps:

[0046] (1-1) Add 30% of the weight of food-grade polyalphaolefin into the blending kettle, and heat it to 50°C under normal pressure; under the premise of satisfying the amount of dissolved additives, adding a small amount of base oil can save heating time and improve production efficiency ;

[0047] (1-2) Add a food-grade anti-wear agent to the food-grade white oil obtained by heating in step (1-1) while stirring, and stir and mix at 52° C. for 40 minutes under normal pressure;

[0048] (1-3) Add food-grade antioxidant, food-grade metal deactivator, food-grade rust inhibitor, food-grade corrosion inhibitor, food-grade oily agent while stirring in the mixture obtained in step (1-2) , Food grade anti-emulsifier, stirring and mixing for 112min, until the mixture is uniform and transparent;

[0049] (1-4) Add a food-grade defoamer to the mixture obtai...

Embodiment 13

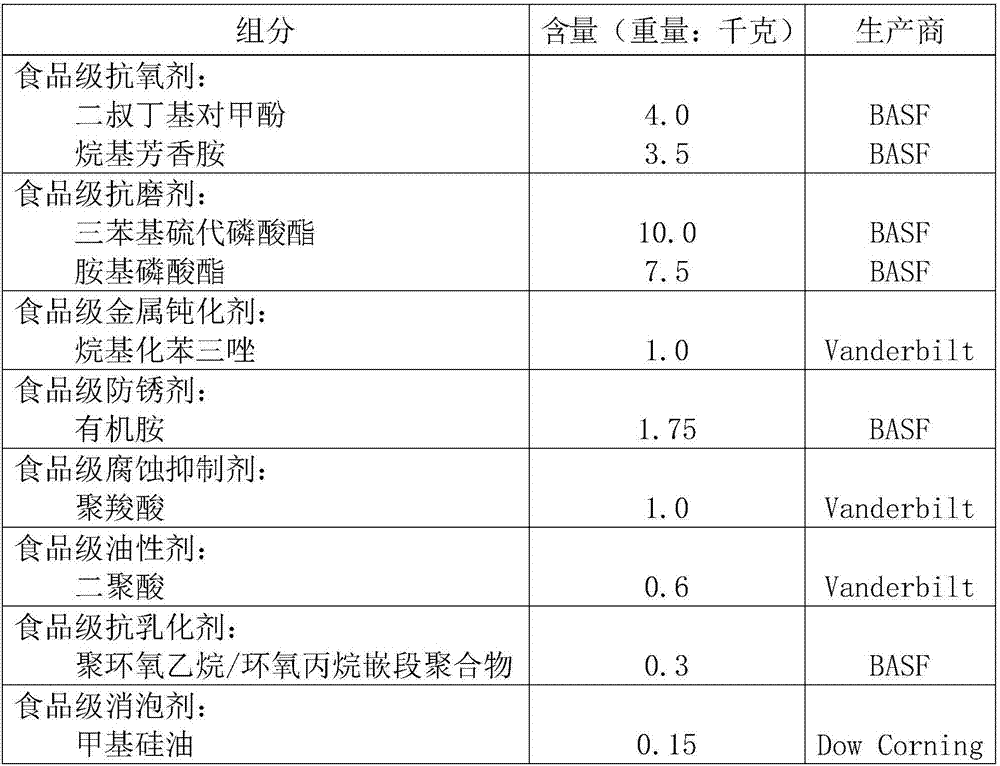

[0051]

[0052]

[0053] The preparation method of the composition that is used for food-grade gear oil, adopts the following steps:

[0054] (1-1) Add 30% of the weight of food-grade polyalphaolefin into the blending kettle, and heat it to 40°C under normal pressure; under the premise of satisfying the amount of dissolved additives, adding a small amount of base oil can save heating time and improve production efficiency ;

[0055] (1-2) Add a food-grade anti-wear agent to the food-grade white oil obtained by heating in step (1-1) while stirring, and stir and mix at 55° C. for 30 minutes under normal pressure;

[0056] (1-3) Add food-grade antioxidant, food-grade metal deactivator, food-grade rust inhibitor, food-grade corrosion inhibitor, food-grade oily agent while stirring in the mixture obtained in step (1-2) , food-grade anti-emulsifier, stirring and mixing for 125 minutes, until the mixture is uniform and transparent;

[0057] (1-4) Add a food-grade defoamer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com