Method for improving photo-thermal excitation micro-cantilever beam vibration energy conversion efficiency by using local plasmon structure

A technology of micro-cantilever beam and plasmon polaritons, which is applied in the direction of using optical devices to transmit sensing components, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of reducing the quality factor of cantilever beams, reducing detection sensitivity, The problem of limited increase and other issues, to achieve the effect of improving energy conversion efficiency, high cost performance, and improving quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for improving the vibration energy conversion efficiency of a photothermally excited micro-cantilever by using a localized plasmon structure, comprising: preparing a localized plasmon structure on the micro-cantilever; The vibration signal emitted.

Embodiment 2

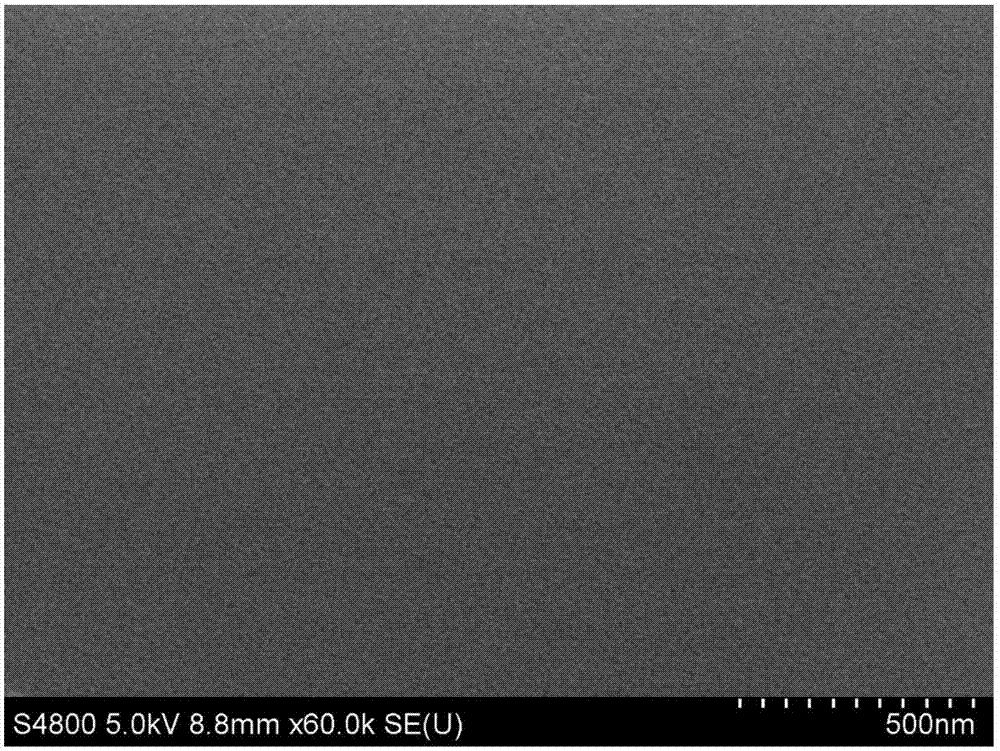

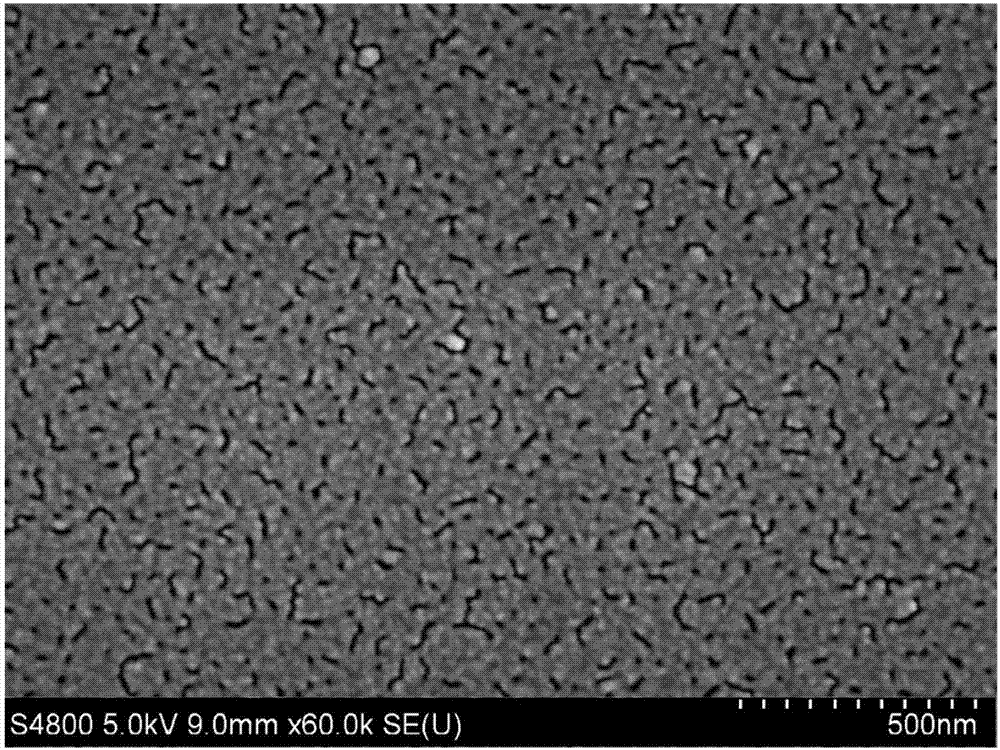

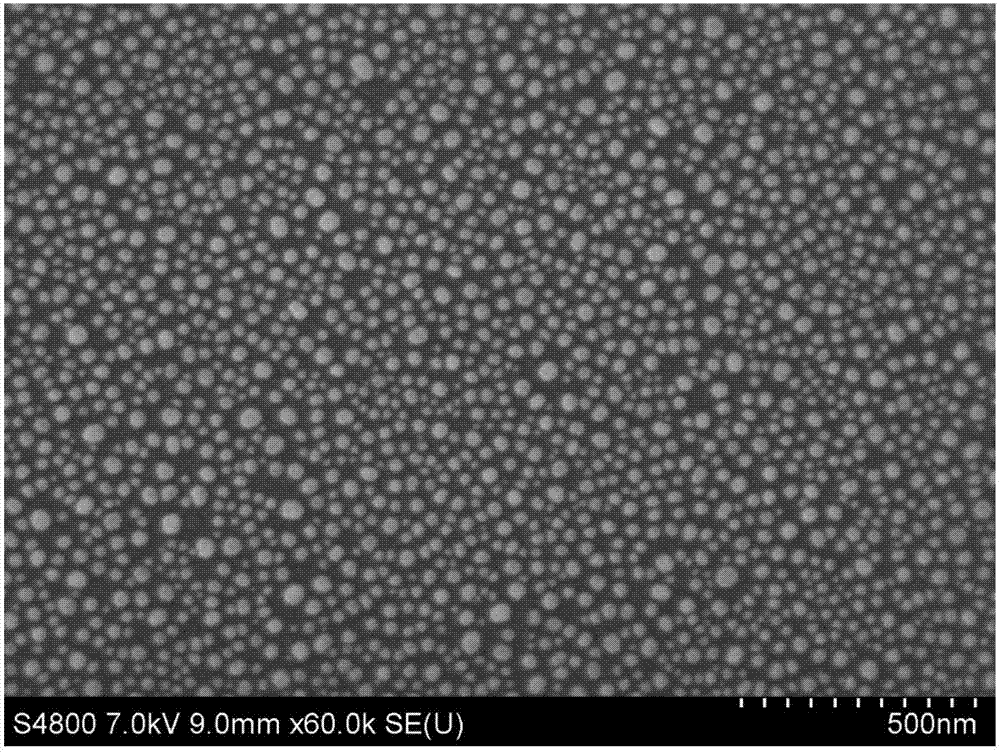

[0044]As described in Example 1, a method of using a localized plasmonic structure to improve the vibration energy conversion efficiency of a photothermally excited micro-cantilever, the difference is that a localized plasmonic structure is prepared on the micro-cantilever The method comprises: sputtering a metal film on a micro-cantilever beam in vacuum, and then annealing the micro-cantilever beam in a nitrogen atmosphere: forming metal nanoparticles on the surface of the micro-cantilever beam.

[0045] The optical wavelength corresponding to the optical excitation is: the optical wavelength that causes the plasmon to resonate.

[0046] The light wavelength corresponding to the light excitation is 365-940nm.

Embodiment 3

[0048] As described in Example 2, a method for improving the vibration energy conversion efficiency of photothermally excited micro-cantilever beams by using a localized plasmon structure, the difference is that the metal film is a gold film; the metal nanoparticles are gold nanoparticles. The light wavelength corresponding to the light excitation is 523nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com