Optical transmit-receive module

A technology of optical transceiver components and optical signals, applied in optical components, light guides, optics, etc., can solve the problems of coupling efficiency drop, two optical paths cannot be aligned with coupling efficiency at the same time, and cannot be integrally formed, so as to simplify the structure and process, The effect of omitting the calibration action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiments of the present invention will be described below with reference to the accompanying drawings in the embodiments of the present invention.

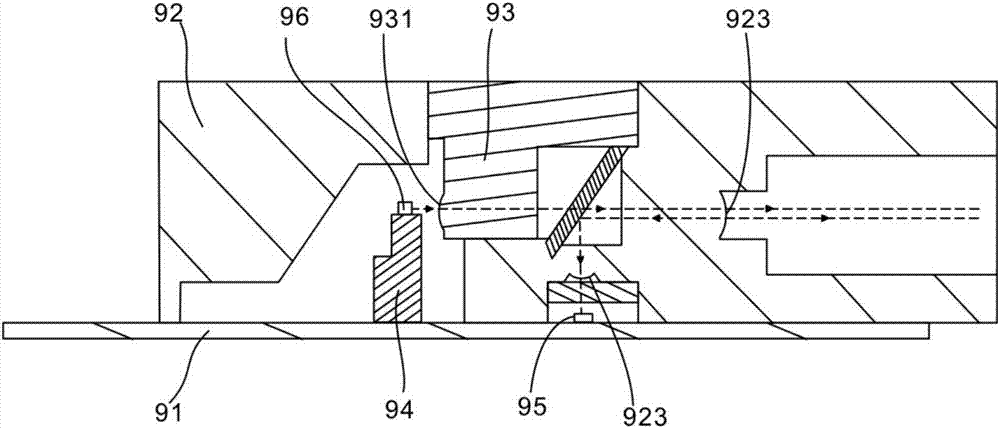

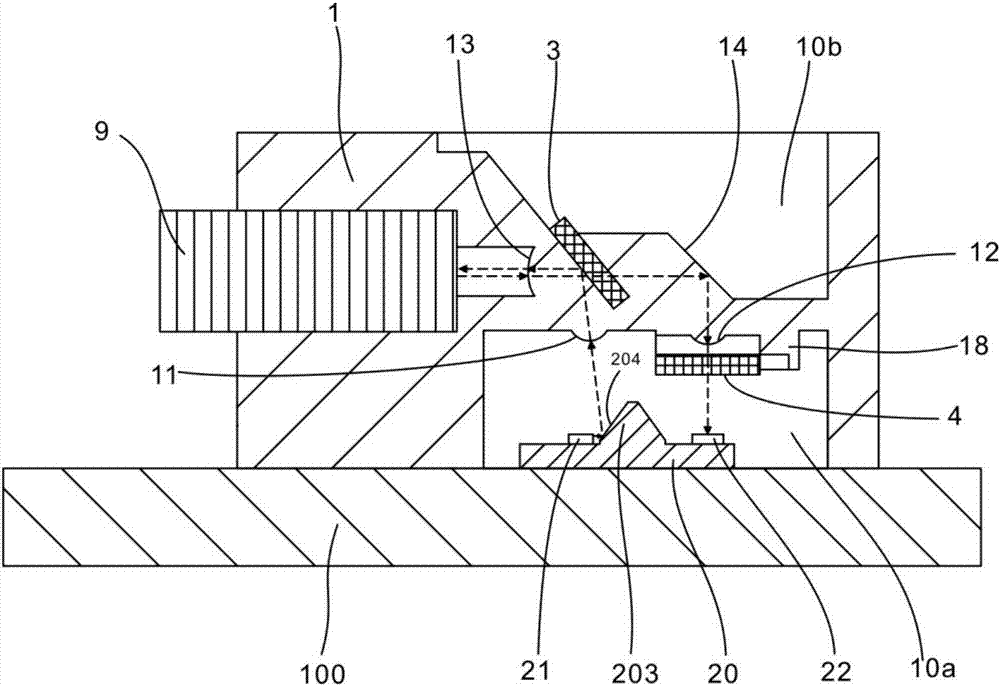

[0044] see figure 2 , is a schematic diagram of an optical transceiver component provided by the first embodiment of the present invention. It should be known that the optical transceiver component is used to convert electrical signals into optical signals (referred to as "electrical-optical conversion") and conduct them into optical fibers, and to conduct and convert optical signals transmitted in optical fibers into electrical signals (referred to as "photoelectric conversion"). ").

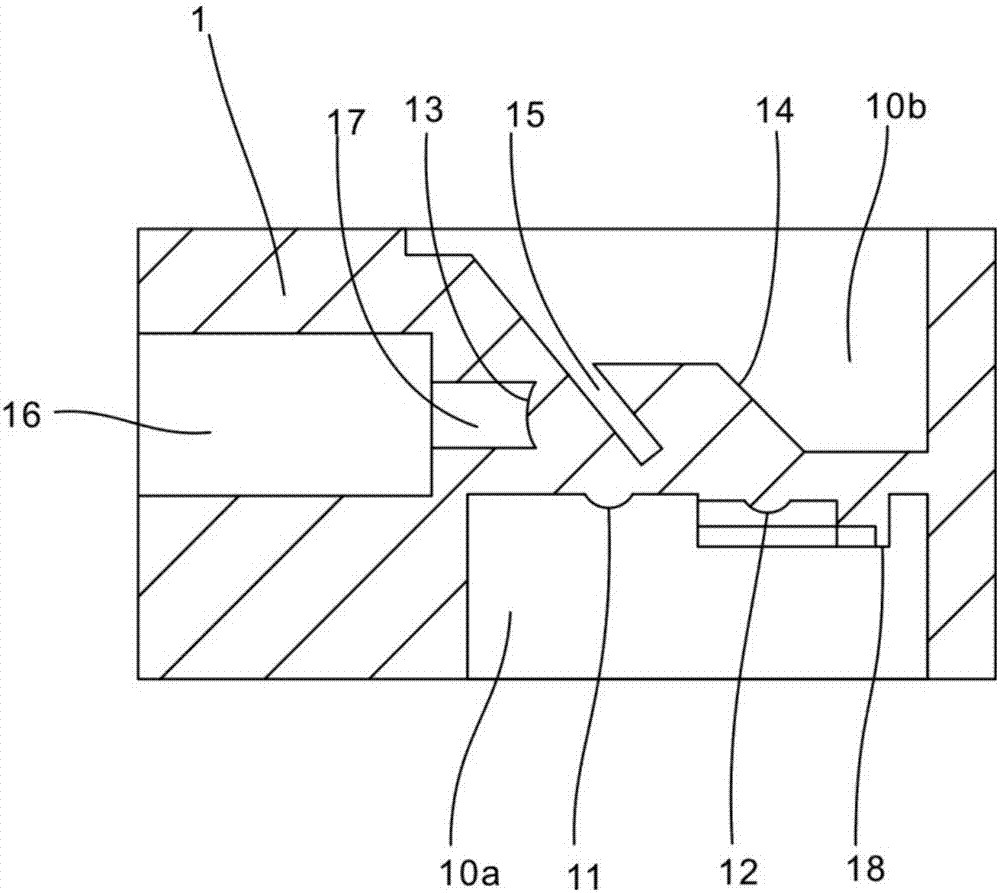

[0045] figure 2 The shown optical transceiver assembly includes a circuit board 100 , a light guide body 1 , a wavelength division multiplexing filter 3 , a first reflective surface 14 , a laser 21 and a detector 22 . The light guide body 1 is fixed on the circuit board 100. The light guide body 1 is integrally formed with a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com