Preparation method for high-efficiency and large-area perovskite solar cell

A solar cell and perovskite technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problem of affecting the quality and photoelectric conversion efficiency of perovskite solar cells, unstable decomposition of perovskite materials, and difficulty in ensuring film formation Uniformity and other issues, to overcome uneven film thickness, improve quality and performance, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

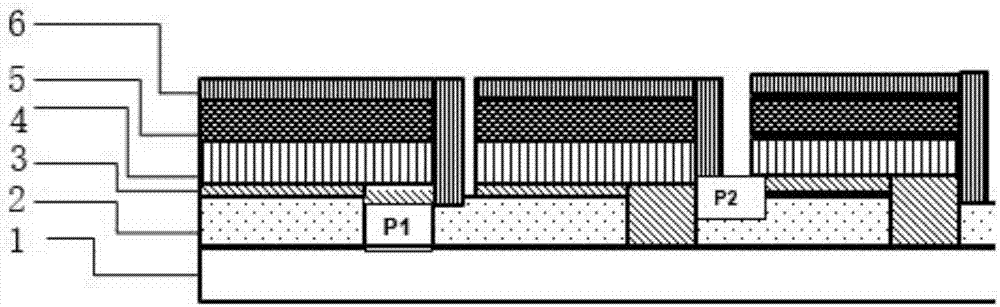

[0027] Perovskite solar cell structures such as figure 1 shown. A method for preparing a high-efficiency large-area perovskite solar cell, specifically comprising the following steps:

[0028] Step 1. Treat the substrate: use ITO glass as the substrate material (the average light transmittance of ITO glass is about 83%), cut it into a suitable size and clean it; when cleaning, use detergent solution, deionized water and ethanol to clean it ultrasonically in sequence 15 to 20 minutes each, blown dry with nitrogen flow, and then irradiated with ultraviolet light for 9 to 11 minutes. The substrate includes a transparent substrate 1 and a conductive layer 2 covering the surface of the transparent substrate 1;

[0029] Step 2: Prepare the hole transport layer 3; laser scribe lines on the processed substrate, and then vapor-deposit copper phthalocyanine (CuPC) on the scribed substrate to form the hole transport layer 3 . The specific process is, in the vacuum chamber, by heating ...

Embodiment 1

[0035] Embodiment 1, this embodiment provides a high-efficiency large-area perovskite solar cell, which includes a transparent substrate 1, a conductive layer 2, a hole transport layer 3, a perovskite active layer 4, an electronic The transmission layer 5 and the metal counter electrode 6, wherein the transparent substrate 1 and the conductive layer 2 are integrated, are collectively referred to as a substrate, and the size of the substrate is 10×10 cm; the manufacturing process of the battery is as follows:

[0036] 1. Treat the substrate: use ITO glass as the substrate material, cut it into a size of 10×10cm, then use detergent solution, deionized water and ethanol to ultrasonically clean it for 15 minutes each, blow it dry with nitrogen flow, and then irradiate it with ultraviolet light for 10 minutes;

[0037] 2. Preparation of the hole transport layer 3; 13 laser lines were carved on the treated substrate with a line spacing of 6 mm; then copper phthalocyanine (CuPC) was v...

Embodiment 2

[0043] Embodiment 2. This embodiment provides a high-efficiency large-area perovskite solar cell, which includes a transparent substrate 1, a conductive layer 2, a hole transport layer 3, a perovskite active layer 4, and an electronic The transmission layer 5 and the metal counter electrode 6, wherein the transparent substrate 1 and the conductive layer 2 are integrated, are collectively referred to as a substrate, and the size of the substrate is 10×10 cm; the manufacturing process of the battery is as follows:

[0044] 1. Treat the substrate: use ITO glass as the substrate material, cut it into a size of 10×10cm, then use detergent solution, deionized water and ethanol to ultrasonically clean it for 15 minutes each, blow it dry with nitrogen flow, and then irradiate it with ultraviolet light for 10 minutes;

[0045] 2. Preparation of the hole transport layer 3; 13 laser lines were carved on the treated substrate with a line spacing of 6 mm; then copper phthalocyanine (CuPC) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com