Graphene-based electrothermal film capable of efficient heat conduction and preparation method thereof

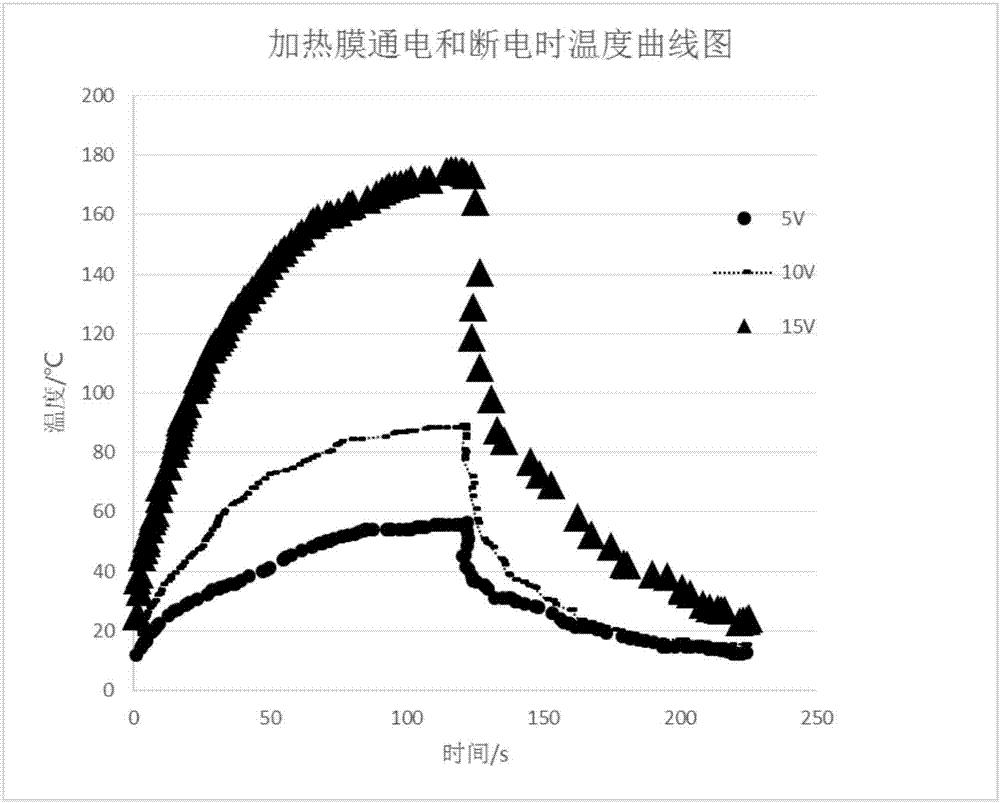

A graphene, electrothermal film technology, applied to conductive layers on insulating carriers, cable/conductor manufacturing, circuits, etc., can solve the problems of low heating rate, high energy consumption, slow thermal conductivity, etc. The effect of shortened rise time and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

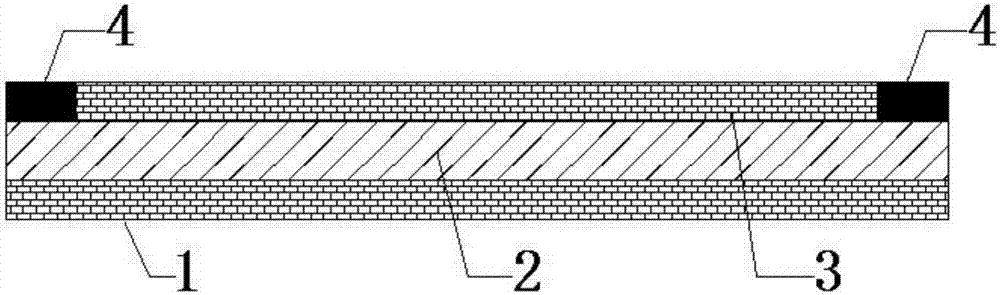

[0026] The preparation method of the electrothermal film based on graphene that can conduct heat efficiently of the present invention is as follows:

[0027] The first step, the preparation of mixed powder: metered by mass percentage, graphene 8%, conductive carbon black 42%, glass powder 35%, ethanol 15%, the powder is dispersed in ethanol solvent as in the mixed ball mill and ground until fully mix;

[0028] The second step, the preparation of organic carrier: measure by mass percentage, terpineol 55%, lipid 25%, ethyl cellulose 6%, dispersant BYK 10%, turpentine other 4%, organic solvent is placed in mixer and mixed uniform;

[0029] The third step, the configuration of the conductive paste: measure by mass percentage, mixed powder 60%, organic vehicle 40%, first add the organic vehicle and mixed powder to the mixer and stir for 10-30min, then transfer to the grinder, grind to two or fully mixed, the particle size of the mixed slurry is less than 15μm;

[0030] The fourt...

Embodiment 2

[0033] The preparation method of the electrothermal film based on graphene that can conduct heat efficiently of the present invention is as follows:

[0034] The first step, the preparation of mixed powder: metered by mass percentage, graphene 16%, conductive carbon black 34%, glass powder 35%, ethanol 15%, the powder is dispersed in ethanol solvent as in mixing ball mill and grinds until fully mix;

[0035] The second step, the preparation of organic vehicle: measure by mass percentage, terpineol 55%, lipid 25%, ethyl cellulose 6%, dispersant BYK10%, turpentine 4%, organic solvent is placed in the blender and mixes ;

[0036] The third step, the configuration of the conductive paste: measure by mass percentage, mixed powder 60%, organic vehicle 40%, first add the organic vehicle and mixed powder to the mixer and stir for 10-30min, then transfer to the grinder, grind to two or fully mixed, the particle size of the mixed slurry is less than 15μm;

[0037] The fourth step, th...

Embodiment 3

[0040] The preparation method of the electrothermal film based on graphene that can conduct heat efficiently of the present invention is as follows:

[0041] The first step, the preparation of mixed powder: metered by mass percentage, graphene 25%, conductive carbon black 25%, glass powder 35%, ethanol 15%, the powder is dispersed in ethanol solvent as in the mixed ball mill and ground until fully mix;

[0042] The second step, the preparation of organic vehicle: measure by mass percentage, terpineol 55%, lipid 25%, ethyl cellulose 6%, dispersant BYK10%, turpentine 4%, organic solvent is placed in the blender and mixes ;

[0043]The third step, the configuration of the conductive paste: measure by mass percentage, mixed powder 60%, organic vehicle 40%, first add the organic vehicle and mixed powder to the mixer and stir for 10-30min, then transfer to the grinder, grind to two or fully mixed, the particle size of the mixed slurry is less than 15μm;

[0044] The fourth step, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com