Quantum dot material, quantum dot photoresist and preparation method of quantum dot photoresist

A quantum dot material and quantum dot technology, applied in the field of quantum dot material modification, can solve the problems of cadmium selenide quantum dot energy level decline, loss of activity, quantum dot material stability and optical efficiency reduction, etc., to improve stability and optical efficiency, guaranteed activity, and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

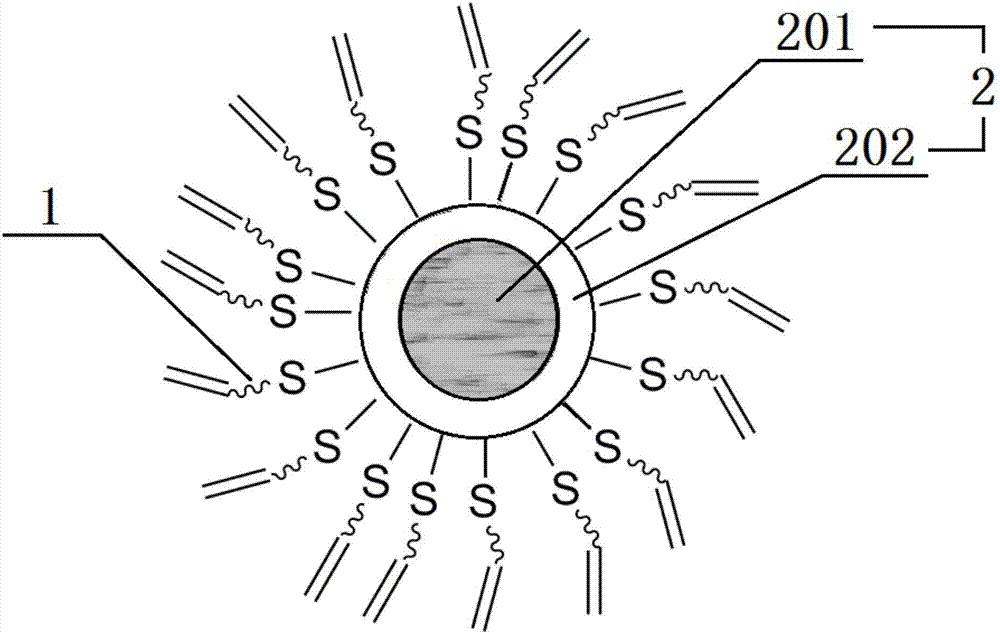

[0057] This embodiment provides a quantum dot material and a quantum dot photoresist including the quantum dot material.

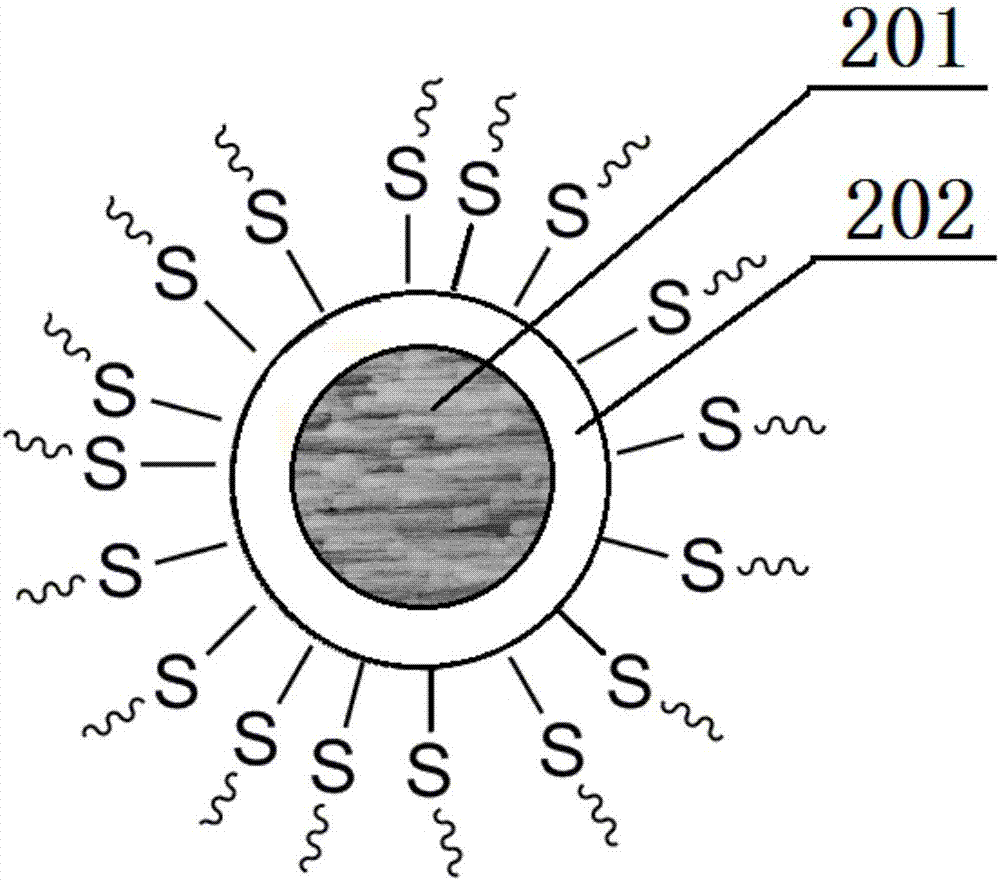

[0058] Specifically, the quantum dot material includes:

[0059] a) Quantum dot core: cadmium selenide,

[0060] b) quantum dot shell wrapped around the quantum dot core: zinc sulfide, and

[0061] c) Surface ligands covering the surface of the quantum dot shell.

[0062] Among them, the general formula of the surface ligand is:

[0063] HS-(-CH 2 -) n -R

[0064] Wherein, n is 1, R is a double bond, that is, the surface ligand is allyl thiol.

[0065] The process of preparing quantum dot photoresist using the quantum dot material is as follows:

[0066] 0.5g allyl mercaptan is mixed with 91g negative photoresist (SU-8 series photoresist produced by U.S. Microlithography Chemical Company (MicrolithographyChemical) to obtain a mixed solution, then add 8.5g in the mixed solution Cadmium selenide quantum dots to obtain quantum dot photoresists.

[00...

Embodiment 2

[0072] This embodiment provides a quantum dot material and a quantum dot photoresist including the quantum dot material.

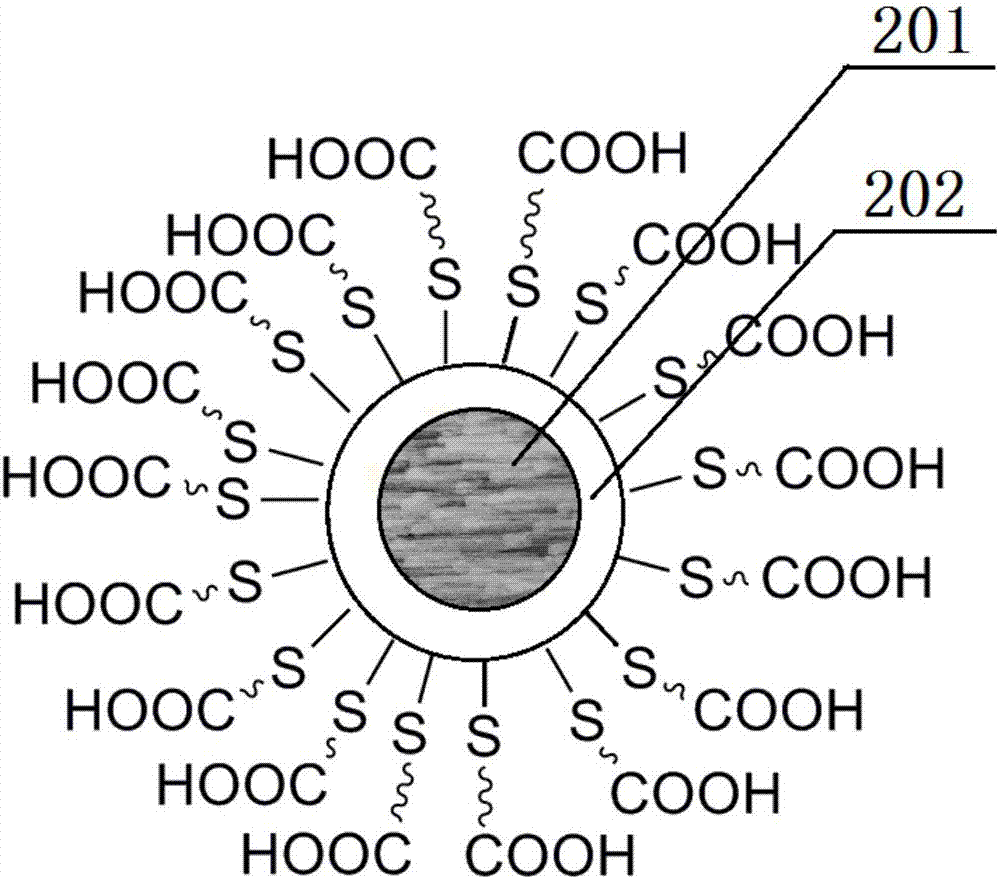

[0073] Specifically, the quantum dot material includes:

[0074] a) Quantum dot core: cadmium selenide,

[0075] b) quantum dot shell wrapped around the quantum dot core: zinc sulfide, and

[0076] c) Surface ligands covering the surface of the quantum dot shell.

[0077] Among them, the general formula of the surface ligand is:

[0078] HS-(-CH 2 -) n -R

[0079] Wherein, n is 1, R is furfuryl, that is, the surface ligand is furfuryl methyl mercaptan.

[0080] The process of preparing quantum dot photoresist using the quantum dot material is as follows:

[0081] Mix 2.2g of allyl mercaptan with 93.8g of negative photoresist (model: SU-8) to obtain a mixed solution, and then add 4g of cadmium selenide quantum dots to the mixed solution to obtain a quantum dot photoresist.

[0082] Wherein, the preparation process of cadmium selenide quantum dots is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com