Biomass porous carbon material based on watermelon peel and preparation method and application of biomass porous carbon material

A biomass and porous carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex preparation process and high preparation cost of supercapacitor electrode materials, and achieve excellent electrochemical performance, high specific surface area, The effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] (1) Preparation of the precursor: Mix the watermelon rind powder that has been dried and pulverized after removing the outer hard peel with the activator, add deionized water, stir magnetically for 5-6 hours in the solution state, and then dissolve the solution at 50- Dry to constant weight at 60 °C to obtain the precursor;

[0027] The mass ratio of above-mentioned activator and watermelon peel powder is 0.05: 1~20: 1, is preferably 1: 1~9: 1;

[0028] The activator is one or more of zinc chloride, phosphoric acid, sodium carbonate, sodium bicarbonate, sodium hydroxide or potassium hydroxide;

[0029] (2) Preparation of biomass porous carbon material: put the above precursor into a graphite crucible, place it in a resistance furnace, and heat it at 3-10 °C min -1 The heating rate is anaerobic heating to 400~1100 ℃ (preferably 600~800 ℃), and then pyrolyzed at this temperature for 1-3h and then lowered to room temperature to obtain a solid powder. °C to a constant wei...

Embodiment 1

[0035] The preparation method of the biomass porous carbon material based on watermelon rind is as follows:

[0036] (1) Take 0.4 g of potassium hydroxide and 0.4 g of dried and pulverized watermelon rind powder (mass ratio: 1:1), put them into a beaker, add 20 mL of deionized water, stir for 5 h, pour Put it into an evaporating dish, dry it in an oven at 60 °C to constant weight, obtain a light yellow solid mixture, and then grind it to obtain a precursor;

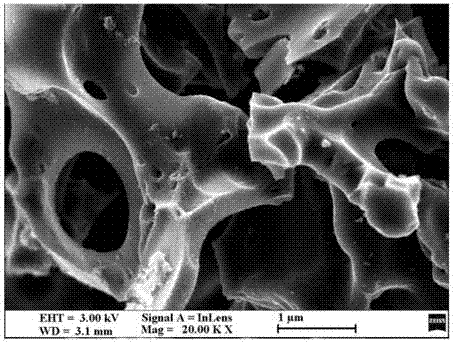

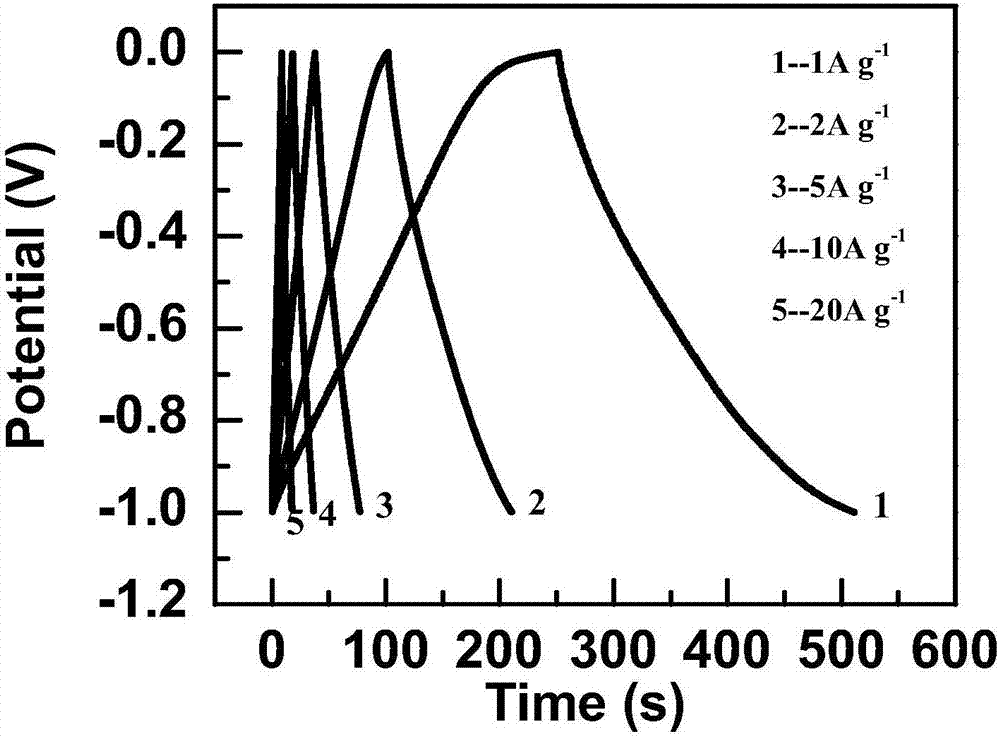

[0037] (2) Put the above precursors into a graphite crucible, place in a resistance furnace, and heat at a rate of 5 °C min -1 Anaerobically heated to 700 °C, then pyrolyzed at this temperature for 1 h, and then cooled to room temperature with the furnace, the obtained black solid powder was subjected to 1 molL -1 Washed with hydrochloric acid and dried to constant weight at 60 °C to obtain a biomass porous carbon material, its scanning electron microscope picture is as follows: figure 1 As shown, it can be seen that th...

Embodiment 2

[0040] The preparation method of the biomass porous carbon material based on watermelon rind is as follows:

[0041] (1) Take 0.8 g of potassium hydroxide and 0.4 g of dried and pulverized watermelon rind powder (mass ratio: 2:1), put them into a beaker, add 20 mL of deionized water, and perform magnetic stirring for 5 h , poured into an evaporating dish, and dried in an oven at 60 °C to constant weight to obtain a light yellow solid mixture, which was then ground to obtain a precursor;

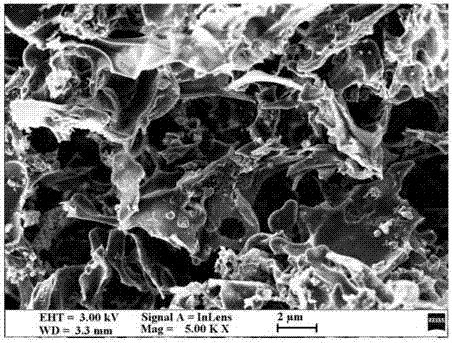

[0042] (2) Put the above precursors into a graphite crucible, place in a resistance furnace, and heat at a rate of 5 °C min -1Anaerobically heated to 700 °C, then pyrolyzed at this temperature for 1 h, and then cooled to room temperature with the furnace, the obtained black solid powder was subjected to 1 molL -1 Washed with hydrochloric acid and dried to constant weight at 60 °C to obtain a biomass porous carbon material, its SEM picture is as follows figure 2 As shown, it can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com